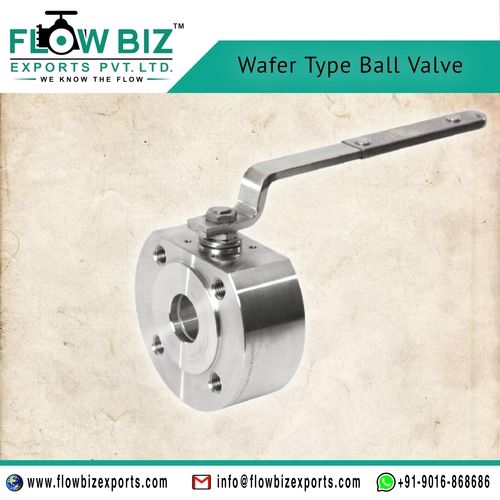

Wafer Type Ball Valve

Price 6000 INR/ Unit

Wafer Type Ball Valve Specification

- Structure

- Wafer Type Ball Valve

- Caliber

- DN15 - DN200

- Pressure

- PN16 / 150 PSI

- Connection

- Wafer / Sandwich Type

- Channels

- Single Channel

- Material

- Stainless Steel / Carbon Steel / Cast Iron

- Power

- Manual

- Media

- Water, Gas, Oil, Acidic Fluids

- Temperature of Media

- -20C to 180C

- Port Size

- 1/2 to 8

- Flange

- ANSI, DIN, JIS Standards

- Finish

- Epoxy Painted / Powder Coated

- Application

- Industrial, Chemical, Water Treatment, Petrochemical, Food Industries

- Ball Material

- Stainless Steel ASTM A351 Gr. CF8 / CF8M

- Anti-static Device

- Provided

- Seal Test Pressure

- 16 bar

- Seat Material

- PTFE / RPTFE / CFT

- Body Material Grades

- WCB, CF8, CF8M

- Fire Safe Design

- Available on Request

- Leakage Class

- Bubble Tight

- End Connection

- Wafer Type (fits between Flanges)

- Mounting Pad

- ISO 5211

- Design Standard

- API 6D / BS 5351

- Suitable Fluids

- Clean Liquids and Gases, Mild Corrosive Media

- Body Test Pressure

- 22 bar

- Operation

- Lever Operated

- Stem Material

- AISI 410 / 304 / 316 Stainless Steel

- Face to Face Dimension

- EN558-1, ISO 5752

About Wafer Type Ball Valve

FlowBiz Wafer Type Ball Valve comes with inbuilt flange tapping that can be installed between flanges with the help of bolts. Wafer Type Ball Valves are low on the area and provide the benefits of flange end Ball Valves while reducing the cost and weight.

FlowBiz Wafer Type Ball Valve is usually a one-piece design and floating ball type. FlowBiz Wafer Type Ball

Valves are available in both cast and forged materials of construction, ranging from DN15 to DN 100, in 150

Class to 900 Class pressure rating. Testing standards as per BS-6755 and API-607.

Size Range :1 inch to 4 inches (25mm to 100mm)

End Connection: Wafer Type

Standard:

Design and Manufacturing: ASME B 16.34 / API 6D

Valve Face-to-Face Dimension: As per Manufacturer

Flange Standard Conformity: ASME B 16.5 Class 150

Inspection And Testing: API 598 / FCI - 70-2 / BS EN 12266-1

Advanced Sealing and Durability

Equipped with seats of PTFE, RPTFE, or CFT, the wafer type ball valve offers excellent resistance to chemical attack and abrasion. The stainless steel ball and stem meet stringent standards for corrosion protection, making the valve ideal for demanding settings where reliability is paramount.

Applications Across Multiple Industries

This ball valve is engineered for adaptability, serving water, oil, gas, and mild acids across various sectors such as chemical processing, water treatment, food, and petrochemical industries. The wafer design makes it easy to install and maintain, enhancing process efficiency for exporters, manufacturers, and suppliers.

Compliance with International Standards

The valve design complies with API 6D, BS 5351, and mounting pad ISO 5211, ensuring global compatibility. Its face-to-face dimensions meet EN558-1 and ISO 5752 requirements, while end connections suit ANSI, DIN, and JIS flanges, providing peace of mind and simplified procurement for international projects.

FAQ's of Wafer Type Ball Valve:

Q: How is the wafer type ball valve installed and what flange standards does it support?

A: Installation is straightforward as the wafer design fits between compatible flanges. The valve supports ANSI, DIN, and JIS flange standards, enabling fast and easy integration into various piping systems without requiring major modifications.Q: What types of fluids and media can this ball valve handle safely?

A: This valve is suitable for clean liquids and gases, mildly corrosive fluids, water, oil, and certain acids. Its stainless steel construction and advanced seat materials (PTFE/RPTFE/CFT) assure reliable performance across these media types from -20C to 180C.Q: When should the fire-safe design option be requested for this wafer type ball valve?

A: Fire-safe design should be requested for operations involving flammable media or environments where fire safety compliance is critical to ensure additional protection against leakage during fire incidents.Q: Where can this wafer type ball valve be used most effectively?

A: It is most effective in industrial, chemical, water treatment, petrochemical, and food industry applications, particularly where space-saving and reliable shut-off are key requirements.Q: What testing and quality standards does the valve conform to?

A: The valve undergoes a 22 bar body test and 16 bar seal test, complies with API 6D and BS 5351 design standards, and ensures bubble-tight leakage class for superior reliability.Q: How does the anti-static device benefit the user?

A: The built-in anti-static device minimizes risk of electrostatic discharge, enhancing safety when handling flammable or sensitive media and reducing process interruptions.Q: What are the advantages of lever-operated manual control for this valve?

A: Lever operation provides simple, direct control for on/off functions, offering immediate feedback for process adjustments, which is ideal for quick shut-off or flow regulation in industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Ball Valve Category

Forged Steel Ball Valve Manufacturer in Gandhidham

Price 2000 INR / Unit

Minimum Order Quantity : 1 Number

Finish : Polished

Application : Industrial, Chemical Processing, Oil & Gas, Water Treatment

Flange : ANSI / DIN / BS Standard

Material : Other, Forged Steel

Ball Valve Manufacturer in Kheda

Price 600 INR / Unit

Minimum Order Quantity : 1 Number

Finish : Polished

Application : Industrial, Agriculture, Water Treatment

Flange : ANSI, DIN, JIS Standard

Material : Stainless Steel

High Pressure Ball Valve Manufacturer in Gandhidham

Price 2000 INR / Unit

Minimum Order Quantity : 1 Number

Finish : Precision Machined, Corrosion Resistant Coating

Application : High Pressure Pipeline, Oil & Gas Industries, Chemical Plants

Flange : ANSI / DIN / BS Standard

Material : Other, Forged Carbon Steel / Stainless Steel / Alloy Steel

Wafer Type Jacketed Ball Valve Manufacturer in Jamnagar

Price 600 INR / Unit

Minimum Order Quantity : 1 Number

Finish : Polished

Application : Industrial

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free