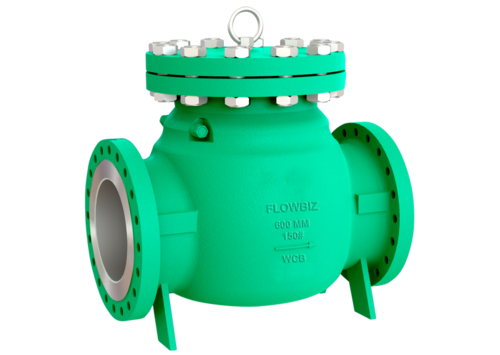

Swing Check Valve Manufacturer in Vadodara

Price 900 INR/ Unit

Swing Check Valve Manufacturer in Vadodara Specification

- Valve Size

- 1/2 to 12

- Features

- Corrosion Resistant, Leakproof, Maintenance Free

- Connection Type

- Flanged, Screwed

- Material

- Cast Iron, Stainless Steel, Carbon Steel, Bronze

- Valve Type

- Check Valve

- Structure

- Swing Type

- Application

- Industrial, Water, Oil & Gas, Chemical Processing, Power Plants

- Sealing

- Soft & Metal Seated

- Type

- Swing Check Valve

- Power

- Manual

- Pressure

- Class 150, PN16, PN25

- Media

- Water, Oil, Gas, Steam

- Port Size

- DN15 to DN300

- Temperature

- -10C to 200C

- Disc

- Swing Type

- Pin

- Stainless Steel

- Operation Method

- Swing

- Suitable Fluid

- Clean & Slightly Contaminated Fluid

- End Connection Standard

- ANSI, DIN, JIS

- Bonnet Type

- Bolted

- Customization

- Available as per Request

- Body Finish

- Epoxy Coated, Painted

- Flow Direction

- One Way

- Service Life

- Long-lasting

- Testing Standard

- API 598

- Face to Face Standard

- ASME B16.10

- Gasket Material

- PTFE, Graphite

- Design Standard

- API 6D / BS EN 12334

- Mounting Position

- Horizontal / Vertical

About Swing Check Valve Manufacturer in Vadodara

Features:

Deal in: New only.

Easily installed.

Smooth functioning.

Prolonged service life.

Delivered within committed time frame.

tested on various quality parameters.

FlowBiz is the best manufacturer of Swing Check Valve in India. We supply Swing Check Valve in Ahmedabad, Vapi, Valsad, Surat, Gandhidham, Kutch, Ankleshwar, Bharuch, Mumbai, Nashik, Pune, Thane, Aurangabad, Satara, Sangli, Nagpur, Kolhapur, Indore, Dewas, Bhopal, Chennai, Coimbatore, Selam and all over India.

Quality and Standards Assurance

Each swing check valve complies with international design standards such as API 6D and BS EN 12334, and is tested as per API 598. End connections are available in ANSI, DIN, and JIS, providing compatibility with global systems. Face-to-face dimensions follow ASME B16.10, ensuring seamless installation and interchangeability for industrial projects.

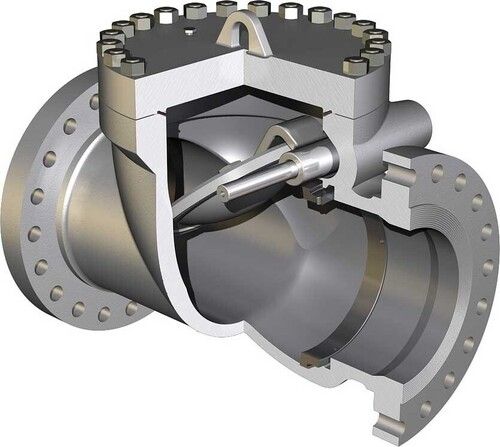

Durable and Versatile Performance

The valves feature robust construction using cast iron, stainless steel, carbon steel, or bronze. Epoxy coated and painted finishes provide enhanced corrosion resistance, and both soft and metal sealing options are available. Designed for both horizontal and vertical mounting positions, these valves offer leakproof, maintenance-free operation and a long service life under demanding temperature and pressure conditions.

Wide Range of Applications

Ideally suited for clean or slightly contaminated fluids, our swing check valves serve water, oil & gas, chemical processing, and power plants. With port sizes from DN15 to DN300, and pressure classes including Class 150, PN16, and PN25, these valves meet the requirements for various industrial installations. Customization is offered to satisfy specific project demands.

FAQ's of Swing Check Valve Manufacturer in Vadodara:

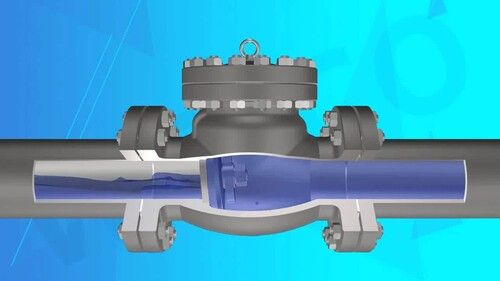

Q: How does a swing check valve ensure one-way flow in industrial applications?

A: A swing check valve uses a swing-type disc that opens to allow flow in one direction and closes when flow reverses, stopping backflow and ensuring reliable one-way movement of water, oil, gas, or steam.Q: What end connection standards are available for these valves?

A: Our swing check valves are manufactured with end connection standards including ANSI, DIN, and JIS. This allows for flexible installation into various existing pipeline systems used worldwide.Q: Where can these swing check valves be installed?

A: These valves are suitable for horizontal or vertical mounting, making them ideal for a wide range of industrial setups such as water treatment plants, oil & gas pipelines, chemical processing units, and power plants.Q: What benefits does the epoxy coating or painted finish provide?

A: Epoxy coated and painted body finishes significantly increase the valve's resistance to corrosion, extending its operational lifespan and ensuring leakproof, maintenance-free performance even in challenging environments.Q: How long is the expected service life, and what makes these valves maintenance-free?

A: Designed for durability with corrosion-resistant materials and a robust structure, the valves offer a long-lasting service life. Precision engineering and high-quality sealing make them maintenance-free under recommended usage conditions.Q: What customization options are available for swing check valves?

A: We offer customization for port sizes, gasket materials (PTFE, Graphite), body material, and more, based on specific application requirements ensuring optimal fit and efficiency for your industrial process.Q: What is the process for quality assurance and valve testing?

A: Each valve is manufactured using design standards such as API 6D and BS EN 12334, with testing conducted as per API 598 to verify structural integrity, leakproof performance, and operational reliability before delivery.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Swing Check Valve Category

Swing Check Valve Manufacturer in Kheda

Price 900 INR / Unit

Minimum Order Quantity : 1 Number

Temperature : 10C to 80C

Application : industrial

Port Size : As per requirement

Disc : Metallic / Rubber Lined

All You Need to Know About Swing Check Valve

Price 3000 INR / Unit

Minimum Order Quantity : 1 Number

Temperature : 10C to 180C

Application : Industrial Pipeline Systems

Port Size : 15mm to 600mm

Disc : Single/Nonreturn Disc

Swing Check Valve Manufacturer in Rajkot

Price 700 INR / Unit

Minimum Order Quantity : 1 Number

Temperature : Up to 200C Celsius (oC)

Application : Process Industries likeChemical, Power, Refinery, Petrochemicals, Nuclear, Water

Port Size : Customized as per requirement

Disc : SS 304

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free