Swing Check Valve Manufacturer in Kheda

Price 900 INR/ Unit

MOQ : 1 Number

Swing Check Valve Manufacturer in Kheda Specification

- Control System

- Manual Operation

- Connection Type

- Flanged End

- Valve Size

- All size

- Material

- Cast Iron / Cast Steel / Stainless Steel

- Features

- Corrosion Resistant, Easy to Install, Durable

- Valve Type

- Non-return

- Structure

- Check

- Application

- industrial

- Usage

- Construction

- Sealing

- Precisely Machined Gasket

- Type

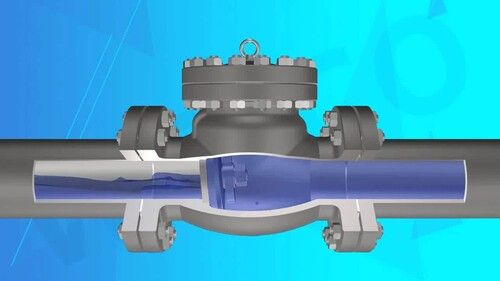

- Swing Check Valve

- Power

- Manual

- Size

- All size

- Pressure

- PN16 / PN25

- Media

- Water, Oil, Gas

- Product Type

- Swing Check Valve

- Port Size

- As per requirement

- Temperature

- -10C to 80C

- Disc

- Metallic / Rubber Lined

- End Connection Standard

- ANSI, DIN, IS

- Coating

- Epoxy Powder Coated

- Body Design

- Full-bore, bolted cover

- Inspection & Testing

- Hydrostatic Pressure Tested

- Leakage Class

- Class VI

- Working Pressure

- Up to 16 Bar

- Face to Face Dimensions

- As per IS / ANSI Standards

Swing Check Valve Manufacturer in Kheda Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 100 Per Week

- Delivery Time

- 7 Days

About Swing Check Valve Manufacturer in Kheda

FlowBiz Exports Swing check valves can regulate and transport water steam oil acetic acid nitric acid solid oxidizing medium and other corrosive media They are usually installed in pipelines for petroleum chemicals and waterbased process flows They suit clean fluid not solidparticleladen or viscosityintensive media

Swing check valves are a standard solution in a variety of industries Power plants refineries and gas transmissions frequently employ swing check valves Swing check valves help prevent the improper flow of gas that could result in dangerous leaks or fires Our valves have broad usage in gas pipelines both in cleaning distribution and compression

Since swing check valves work well with large predictable flow they are frequently used in wastewater treatment and water pumping

Full-Bore, Durable Design

Our swing check valves feature full-bore passage and a robust bolted cover for maximum strength and minimal flow restriction. Manufactured from cast iron, steel, or stainless steel, their integrity is enhanced by an epoxy powder coating, providing lasting corrosion resistance in demanding environments.

Precision Engineering and Testing

Each valve is hydrostatically pressure-tested and adheres to strict leakage standards (Class VI). The sealing system is a precisely machined gasket, ensuring reliable performance and leak prevention under working pressures up to 16 Bar.

Versatile Application and Standards Compliance

Designed to meet ANSI, DIN, and IS standards, these valves are compatible with a variety of industrial and construction systems. The flanged end connections and manual control provide both flexibility and ease of use, supporting water, oil, or gas flow applications.

FAQ's of Swing Check Valve Manufacturer in Kheda:

Q: How are your swing check valves tested for quality and reliability?

A: All our swing check valves undergo rigorous hydrostatic pressure testing to ensure they meet national and international leakage Class VI standards. This process validates the valve's durability and leak-proof performance under working pressures up to 16 Bar.Q: What sizes and connection standards are available for your swing check valves?

A: We offer swing check valves in all sizes, with port size customizable upon request. End connections are manufactured to ANSI, DIN, and IS standards, ensuring compatibility with a wide range of piping systems in industrial and construction sectors.Q: What types of media are suitable for use with your swing check valves?

A: These valves are optimized for use with water, oil, and gas. The robust material choices and precision sealing make them suitable for various industrial environments dealing with these fluids.Q: When is it advisable to use an epoxy powder-coated swing check valve?

A: Epoxy powder-coated swing check valves are ideal when corrosion resistance and long-term durability are required-such as in demanding industrial, construction, or outdoor installations exposed to moisture and chemicals.Q: Where are your swing check valves commonly installed?

A: Our valves are widely installed in construction pipelines, industrial fluid transport systems, and infrastructure projects throughout India and globally, wherever dependable non-return flow control is needed.Q: What are the benefits of manual operation for these valves?

A: Manual operation allows for straightforward, user-controlled flow regulation without the need for complex automation, providing simplicity, reliability, and cost-effectiveness in a variety of operational settings.Q: What process do you follow to ensure your valves match project specifications?

A: Every valve is manufactured according to client requirements-starting from material selection to sizing and end connection type. We adhere to face-to-face dimension standards (IS/ANSI) and apply strict inspection before dispatch to guarantee project compatibility.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Swing Check Valve Category

Swing Check Valve Manufacturer in Vapi

Price 1900 INR / Unit

Minimum Order Quantity : 1 Number

Type : Check Valve

Application : Industrial, Water, Oil, Gas, Steam piping systems

Media : Other, Water, Oil, Air, Gas, Steam

Pressure : Other, Up to 40 Bar

Forged Steel Swing Check Valve

Price 16000 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Forged Steel Swing Check Valve

Media : Gas

Pressure : High Pressure

Audco (L T) Make Swing Check Valve

Price 1800 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Audco (L T) Make Swing Check Valve

Application : Industrial

Pressure : High Pressure

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS