SS Diaphragm Valve Manufacturer in Rajkot

Price 500 INR/ Unit

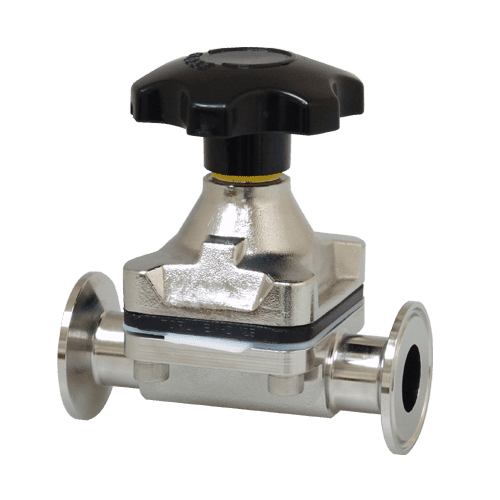

SS Diaphragm Valve Manufacturer in Rajkot Specification

- Color

- Silver

- Usage

- Industrial

- Type

- Diaphragm Valves

- Material

- Stainless Steel

- Size

- Standard Sizes

- Product Type

- SS Diaphragm Valve

SS Diaphragm Valve Manufacturer in Rajkot Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 1000 Per Month

- Delivery Time

- 7 Days

About SS Diaphragm Valve Manufacturer in Rajkot

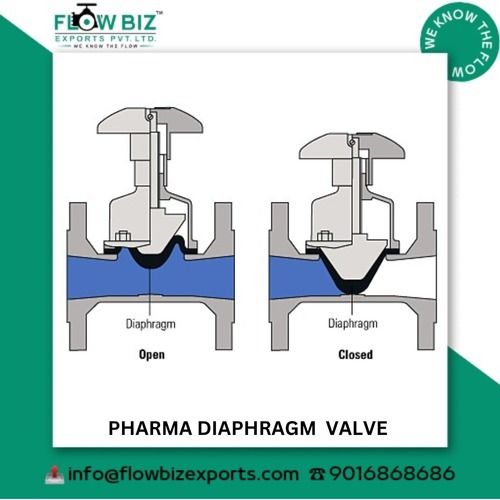

Pharma Diaphragm Valve

Operating Principles

FlowBiz Pharma Diaphragm provides a seal body along with a seat seal. The closed design makes the valve disconnected from the outside environment, making the valve suitable for aseptic processes.

The pressure pad supporting the Diaphragm moves towards the body, sealing the face when the valve is closed. The flow path is completed through the body when the pressure plate moves, flexing the Diaphragm & forcing it down onto the seal area in the body's centre. The inter-relationship of the body to the pressure plate prevents Over-compression of the Diaphragm.

FlowBiz Pharma Diaphragm Valves have two operational variants, manually and pneumatically controlled by control tops and solenoid valves.

Size Range: 1/2 inch to 3 inches (15mm to 80mm)

End Connection: Tri-Clover End

Applications:

Specially engineered for use in the pharmaceutical industries' hygienic and aseptic process.

Excellent results for flow control and open/close duties.

Precision-Engineered SS Diaphragm Valves

Crafted from premium stainless steel, our diaphragm valves offer exceptional corrosion resistance and mechanical integrity. These valves are ideal for regulating flow in harsh industrial environments, thanks to their robust construction and easy maintenance. Each valve undergoes rigorous quality checks to ensure superior performance and long-lasting reliability.

Standard Sizes for Versatile Industrial Application

Our SS diaphragm valves are available in a range of standard sizes, catering to diverse industrial requirements. This adaptability makes them suitable for systems demanding precise flow control, while simplifying installation and inventory management for different sectors.

FAQ's of SS Diaphragm Valve Manufacturer in Rajkot:

Q: How are stainless steel diaphragm valves commonly used in industrial settings?

A: Stainless steel diaphragm valves are frequently used to regulate or stop the flow of liquids, gases, or slurries in various industrial processes such as chemical manufacturing, water treatment, food processing, and pharmaceuticals. Their sanitary design and corrosion resistance make them ideal for systems requiring frequent cleaning or handling aggressive media.Q: What is the manufacturing process of your SS diaphragm valves?

A: Our SS diaphragm valves are manufactured using high-grade stainless steel through precision casting, machining, and assembly. Each valve is fitted with a high-quality diaphragm and undergoes thorough pressure and leakage testing, ensuring reliable performance and durability even in demanding industrial environments.Q: When should I choose a diaphragm valve over other valve types?

A: Diaphragm valves are preferable when you require tight shut-off and control in applications involving corrosive, abrasive, or viscous fluids. They are especially useful in sanitary or high-purity processes, as their design minimizes dead space where contaminants can accumulate.Q: Where can your SS diaphragm valves be supplied or exported?

A: As a prominent exporter, manufacturer, and supplier from Rajkot, India, we provide our SS diaphragm valves to customers nationwide and in international markets. Our efficient logistics network ensures timely delivery and reliable support for clients across industries.Q: How do I select the appropriate standard size for my application?

A: Choosing the correct size involves considering the flow rate, pressure, and connection specifications of your system. Our expert team can assist you in identifying the optimal valve size based on your process requirements and technical parameters.Q: What are the primary benefits of using stainless steel diaphragm valves in industrial applications?

A: The key advantages include superior resistance to corrosion, excellent mechanical strength, low maintenance, and suitability for hygienic or hazardous processes. Their versatility and robust build enhance operational safety and longevity in diverse industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Diaphragm Valve Category

Pilot Operated Diaphragm Type Solenoid Valve (NC)

Price 12000 INR / Number

Minimum Order Quantity : 1 Unit

Material : Other , Brass Body, NBR Diaphragm, Stainless Steel Internals

Color : Golden Body with Black Coil

Power : Other, 1015W

Size : Compact/Midi Range

Pharma Diaphragm Valve

Price 9000 INR / Unit

Minimum Order Quantity : 1 Number

Material : Other , Stainless Steel (SS 316/316L)

Color : Silver / Metallic Finish

Power : Other, Manual, Pneumatic or Electric Actuation

Size : Customized sizes available

Diaphragm Valve Manufacturer in Junagadh

Price 5000 INR / Unit

Minimum Order Quantity : 1 Number

Material : Stainless Steel

Color : Green

Power : Manual

Size : Standard Sizes

SS Diaphragm Valve Manufacturer in Gandhidham

Price 1700.00 INR / Unit

Minimum Order Quantity : 1 Number

Material : Stainless Steel

Color : Silvar

Power : Manual

Size : 1/2 inch

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS