Pilot Operated Diaphragm Type Solenoid Valve (NC)

Price 12000 INR/ Number

Pilot Operated Diaphragm Type Solenoid Valve (NC) Specification

- Size

- Compact/Midi Range

- Application

- Industrial Automation, Water Treatment, Pneumatic Systems, HVAC, Irrigation

- Voltage

- 230V AC / 24V DC (Other voltages on request)

- Color

- Golden Body with Black Coil

- Connection

- Threaded (BSP/NPT)

- Pressure

- 0.5 to 10 Bar

- Type

- Pilot Operated Diaphragm Type Solenoid Valve (NC)

- Material

- Brass Body, NBR Diaphragm, Stainless Steel Internals

- Temperature

- -10C to +80C

- Media

- Air, Water, Gas, Oil

- Standard

- ISO certified

- Power

- 10-15W

- Port Size

- 1/2 inch, 3/4 inch, 1 inch, 1-1/2 inch, 2 inch

- Model

- PODSV-NC Series

- Characteristics

- Normally Closed, High Flow Rate, Low Noise, Long Life Span

- Mounting Position

- Any, preferably upright

- Coil Protection Class

- IP65

- Ambient Temperature

- Up to 50°C

- Body Finish

- Nickel Plated Brass

- Orifice Size

- 13 mm to 50 mm

- End Connection

- Screwed Ends

- Cycle Life

- Over 1 Million Operations

- Response Time

- < 1 sec

- Suitable Fluids

- Clean Liquids and Gases

- Weight

- Depends on port size, approx. 0.5 to 2.5 kg

- Seal Material

- NBR (Standard), Optional FKM/EPDM

- Manual Override

- Optional

About Pilot Operated Diaphragm Type Solenoid Valve (NC)

Port : Refer below technical data sheet (Available BSP / NPT)

End Connection : Screwed / Flange

Body Material : SS ASTM A351 Grade CF8 / CF8M, Forged Brass

Circumstance Temp : -10C to 70C

Media : Air, Water, Chemical, Gas, Oil, Diesel, Kerosene, LPG.

Main Features : Internal Parts are in superior corrosion resistance steel,

(Equivalent to SS316L) Suitable for Food Industries, Pharmaceuticals,

Chemical application & Highly corrosive environment.

Coil Features : High Reliability Unaffected by Voltage Surges.

Easy coil changes coil lockable in 4X90 position or freely movable in

between as require.

Coil Housing : Epoxy square coil, Metallic round enclosure,

IP-68 Weatherproof enclosure

Optional Feature : 90% Power saver series also available, Manual Override,

Water hammering reducer also available to avoid water hammer

forces

Other Specification Data : Available on Request

Versatile Construction and Reliable Performance

With nickel plated brass body, NBR diaphragm, and stainless steel internals, the PODSV-NC Series valve ensures durability in challenging environments. Its compact size and various orifice options fit a wide range of industrial applications, offering consistent response and extended life span over one million cycles.

Flexible Installation and Operation

The valve's design allows for mounting in any position, with preference for upright installation for optimal performance. Threaded ends (BSP/NPT) and optional manual override enhance its usability across diverse systems, enabling fast installation and easy maintenance.

Wide Media Compatibility and Safety Features

Suitable for air, water, gas, and oil, the valve's seal options (NBR, FKM, EPDM) increase chemical compatibility. The IP65 coil protection ensures operational safety in harsh conditions, supporting ambient temperatures up to 50C and pressure range of 0.5-10 Bar.

FAQ's of Pilot Operated Diaphragm Type Solenoid Valve (NC):

Q: How does the manual override function work on the PODSV-NC Series valve?

A: The manual override is an optional feature that allows users to operate the valve manually during power outages or maintenance without activating the solenoid coil. This ensures continued flow control even when electrical power is unavailable.Q: What fluids and gases are suitable for use with this solenoid valve?

A: The valve is designed for clean liquids and gases, including air, water, oil, and gas. Its seal materials (NBR standard, with FKM or EPDM optional) offer resistance to a broad spectrum of media, expanding compatibility across many industrial fluids.Q: When should the valve be mounted in an upright position?

A: While the valve can be mounted in any position, upright installation is preferred for optimal performance and longevity. This orientation helps prevent debris accumulation and ensures reliable pilot operation, especially in high-cycle applications.Q: Where is the PODSV-NC Series typically used?

A: This valve is widely used in industrial automation, water treatment, pneumatic systems, HVAC, and irrigation due to its high flow rate, low noise emissions, and long life span. Its robust construction ensures reliability in demanding environments.Q: What is the process for selecting seal material for specific media?

A: To choose the appropriate seal material, evaluate the media's chemical properties and temperature range. NBR suits most standard fluids, while FKM or EPDM seals are recommended for aggressive chemicals or higher temperature applications to maintain performance and safety.Q: How does coil protection class IP65 benefit valve operation?

A: IP65 rated coil protection guards against dust ingress and water jets, making the valve suitable for operation in harsh and moist environments. This enhances safety, reduces downtime, and prolongs both the coil and valve's operational life.Q: What are the benefits of the pilot operated diaphragm design in this solenoid valve?

A: Pilot operated diaphragm construction delivers high flow rates and rapid response times (less than 1 second), enabling precise control in complex systems. It reduces noise, supports longer cycle life, and handles pressures from 0.5 to 10 Bar efficiently.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Diaphragm Valve Category

SS Diaphragm Valve Manufacturer in Jamnagar

Price 700 INR / Unit

Minimum Order Quantity : 1 Number

Material : Other , Stainless Steel (SS)

Color : White

Connection : Other, Flanged / Screwed / Butt Weld / Socket Weld

Size : Customized / Standard

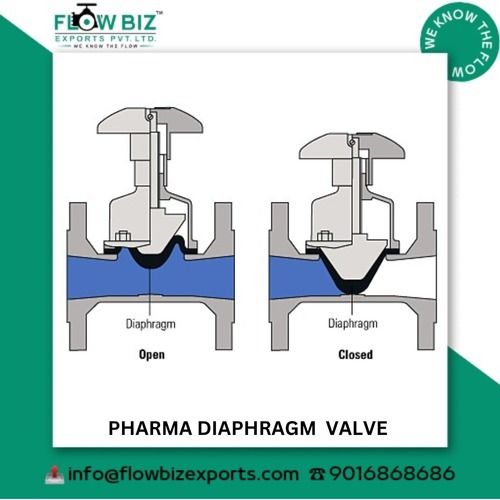

Pharma Diaphragm Valve

Price 9000 INR / Unit

Minimum Order Quantity : 1 Number

Material : Other , Stainless Steel (SS 316/316L)

Color : Silver / Metallic Finish

Connection : Other, TriClamp, Welded Ends, Threaded

Size : Customized sizes available

PTFE Lined Diaphragm Valve Manufacturer in Pune

Price 700.00 INR / Unit

Minimum Order Quantity : 1 Number

Material : Cast Iron

Color : Blue

Connection : Flange Type

Size : 1/2" to 12"

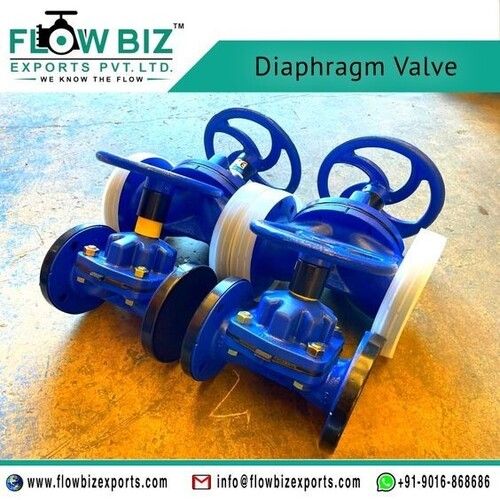

Diaphragm Valve Manufacturers in Rajkot

Price 3000 INR / Unit

Minimum Order Quantity : 1 Number

Material : Stainless Steel

Color : Blue

Connection : Flange Type

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS