Pharma Diaphragm Valve

Price 9000 INR/ Unit

Pharma Diaphragm Valve Specification

- Connection

- Tri-Clamp, Welded Ends, Threaded

- Size

- Customized sizes available

- Application

- Pharmaceutical, Biotechnology, Food & Beverage, Chemical Processing

- Voltage

- 24V / 230V for Electric Actuators

- Pressure

- Vacuum to 10 Bar

- Color

- Silver / Metallic Finish

- Type

- Pharma Diaphragm Valve

- Material

- Stainless Steel (SS 316/316L)

- Temperature

- -20C to 200C

- Media

- Liquids, Gases, Clean/Corrosive Fluids

- Standard

- ASME BPE, DIN, ISO

- Power

- Manual, Pneumatic or Electric Actuation

- Port Size

- 1/2 inch to 4 inch

- Model

- Pharma Grade Diaphragm Valve

- Characteristics

- Leak-proof Isolation, GMP Design, CIP/SIP Compatible

- Control Options

- On/Off or Modulating Control

- Availability

- Ready Stock / Made to Order

- Body Finish

- Electropolished/Mechanical Polish (Ra 0.5m)

- Weight

- Varies as per size and model

- End Connection

- Tri-Clamp, Butt Weld, Flanged

- Sealing

- Hermetically sealed, replacement diaphragm

- Mounting Position

- Any orientation

- Diaphragm Material

- EPDM, PTFE, Silicone, FKM

- Maintenance

- Easy to disassemble and clean

- Operation

- Handwheel, Pneumatic, Electric

- Surface Roughness

- 0.5 m

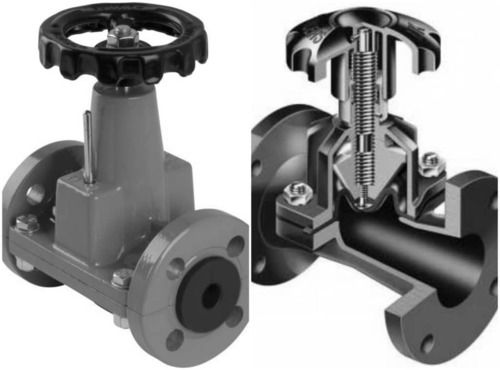

About Pharma Diaphragm Valve

Pharma Diaphragm Valve

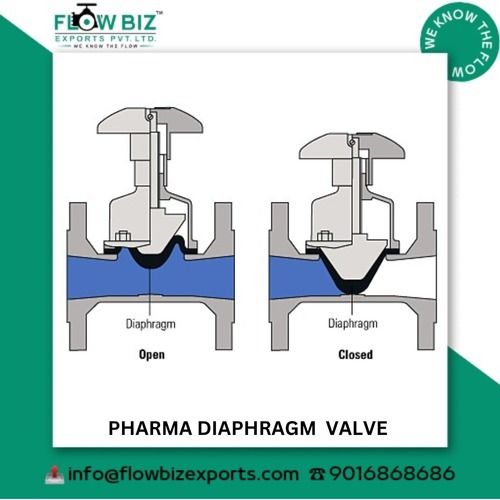

Operating Principles:FlowBiz Pharma Diaphragmprovides a seal body along with a seat seal. The closed design makes the valve disconnected from the outside environment, making the valve suitable for

aseptic processes.The pressure pad supporting the Diaphragm moves towards the body, sealing the face when the valve is closed. The flow path is completed through the body when the pressure plate moves, flexing the Diaphragm and forcing it down onto the seal area in the bodys centre. The inter relationship of the body to the pressure plate prevents Over-compression of the Diaphragm.

FlowBiz Pharma Diaphragm Valves have two operational variants, manually and pneumatically controlled by control tops and solenoid valves.

Size Range: 15mm to 80mm

End Connection: Tri Clover End

Applications:

Specially engineered for use in the pharmaceutical industries hygienic and aseptic process.

Excellent results for flow control and open/close duties.

Ultra-Hygienic Construction

Featuring an electropolished or mechanical polish finish, these diaphragm valves maintain a surface roughness of 0.5 m, minimizing bacterial adherence. The hermetically sealed design ensures contamination-free operation and leak-proof isolation, making them ideal for sterile processes in pharmaceutical, biotech, and food industries.

Versatile Actuation and Mounting

Available with manual, pneumatic, or electric actuators, these valves cater to a broad spectrum of control requirements. They can be installed in any orientation without performance loss, and are compatible with Tri-Clamp, Welded, Flanged, or Threaded end connections for seamless integration into existing pipelines.

Simplified Maintenance and Control

The valves are engineered for quick disassembly and cleaning, supporting CIP and SIP maintenance routines. Replacement diaphragms can be easily installed, reducing downtime. Users can choose between on/off or modulating control, depending on process needs, for precise fluid handling.

FAQ's of Pharma Diaphragm Valve:

Q: How do Pharma Diaphragm Valves ensure leak-proof isolation in pharmaceutical processes?

A: These valves feature hermetically sealed construction and precision-engineered diaphragms, creating a robust barrier that prevents fluid leakage and cross-contamination, crucial for maintaining GMP compliance and product integrity in sterile environments.Q: What diaphragm materials are available, and how do I select the right one for my media?

A: Diaphragms are offered in EPDM, PTFE, Silicone, and FKM. Selection depends on media compatibility: EPDM is ideal for aqueous solutions, PTFE for aggressive chemicals and high temperatures, Silicone for flexibility, and FKM for resistance to corrosive fluids.Q: When is it necessary to replace the diaphragm, and what is the process?

A: Diaphragm replacement is recommended during scheduled maintenance or if wear, deformation, or chemical attack is noticed. The valve's design allows quick disassembly; simply unmount the bonnet, remove the worn diaphragm, and install the new one, ensuring proper sealing before reassembly.Q: Where can these valves be installed within a process line?

A: They can be mounted in any orientation-horizontal, vertical, or angular-without compromising performance or sealing integrity, making them highly versatile for complex piping layouts in pharmaceutical, biotech, and food facilities.Q: What are the benefits of the electropolished surface finish (Ra 0.5m)?

A: The ultra-smooth electropolished finish greatly reduces microbial adhesion and facilitates easy cleaning, supporting high standards of hygiene and sterilization required in sensitive production environments.Q: How does operation differ between manual, pneumatic, and electric actuators?

A: Manual handwheel actuation offers straightforward control for low-cycle processes, while pneumatic and electric options enable remote and automatic operation, allowing integration with process automation for modulating or rapid on/off control.Q: What makes these valves compatible with CIP/SIP procedures?

A: Their design and selection of materials withstand cleaning and sterilization in place (CIP/SIP). Smooth surfaces, the ability to fully disassemble, and high-grade alloys ensure that no residues remain, supporting compliance with pharmaceutical hygiene standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Diaphragm Valve Category

Pilot Operated Diaphragm Valve (NO)

Price 7000 INR / Number

Minimum Order Quantity : 1 Unit

Size : Standard sizes available (customizable)

Color : Golden Brass

Material : Other , Brass Body with NBR or EPDM Diaphragm

Wafer Type Damper Valve Manufacturer in Kheda

Price 1500 INR / Unit

Minimum Order Quantity : 1 Number

Size : All size

Color : Blue

Usage : Construction

Diaphragm Valve Manufacturer in Mandvi

Price 3000.00 INR / Unit

Minimum Order Quantity : 1 Number

Size : 1/2" to 12"

Color : Gray

Usage : Industrial

Material : Stainless Steel

SS Diaphragm Valve Manufacturer in Vadodara

Price 2000.00 INR / Unit

Minimum Order Quantity : 1 Number

Size : 1/2" to 12"

Color : Silvar

Usage : Industrial

Material : Stainless Steel

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free