Metal Seated Ball Valve Manufacturer in Kheda

Price 800 INR/ Unit

Metal Seated Ball Valve Manufacturer in Kheda Specification

- Channels

- 2-Way / 3-Way

- Structure

- Floating / Trunnion Mounted

- Caliber

- Full Bore / Reduced Bore

- Connection

- Flanged / Screwed / Welded

- Pressure

- Class 150 to Class 2500 (PN16PN420)

- Material

- Stainless Steel / Alloy Steel / Carbon Steel

- Power

- Manual / Pneumatic / Electric

- Media

- Water, Gas, Oil, Steam, Chemical

- Temperature of Media

- -29C to +425C

- Port Size

- 1/2 to 16 (DN15DN400)

- Flange

- ANSI / DIN / BS Standard

- Finish

- Precision Machined, Corrosion Resistant

- Application

- Petrochemical, Power Plant, Oil & Gas, Water Treatment, Chemical Processing

- Operation

- Quarter Turn

- Anti-static Device

- Provided

- Body Test Pressure

- 1.5 x Rated Pressure

- Ball Material

- A105 / F304 / F316 / Duplex

- Design Standard

- API 6D / BS 5351 / ASME B16.34

- Fire Safe Design

- Available as per API 607

- End Connection

- Butt Weld / Socket Weld / Threaded

- Coating

- PTFE or Hard Chrome Plated Ball

- Leakage Rating

- ISO 5208 Rate A, Zero Leakage

- Seat Type

- Metal to Metal

- Blowout Proof Stem

- Yes

- Stem Seals

- PTFE / Graphite

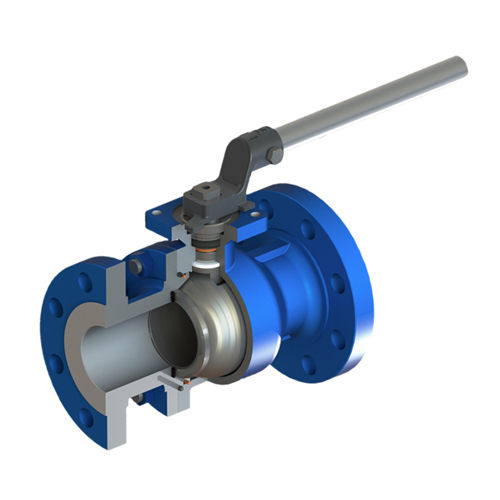

About Metal Seated Ball Valve Manufacturer in Kheda

FlowBiz Exports Metal Seated ball valve is a check valve that uses a seated disc to perform its function. It works by closing off flow through the passage when it is in the open position and allowing it to flow again when it is in the closed position.

Metal Seated Ball Valves are designed for severe conditions such as high temperature, high pressure, and abrasive fluids in oil and gas, petroleum, petrochemical, power generation, chemical, pulp and paper, and mining.

Applicable Standards

Design standard: ISO17292/ API 6D

Testing standard: BS6755/ API598

Pressure-Temperature rating: ASME B-16.34

Flange Dimensions: ASME B-16.5

Face to Face: ASME B-16.10

High Performance Metal Seated Ball Valves

Our metal seated ball valves are engineered for critical conditions, delivering zero leakage as per ISO 5208 Rate A. With robust designs such as floating or trunnion mounted structures, they excel in severe service, handling water, gas, oil, steam, and aggressive chemicals. Choose from a range of materials like stainless steel, alloy steel, or carbon steel, ensuring resilience and longevity in diverse media environments.

Precision and Safety in Every Valve

All valves undergo a stringent 1.5 x rated body test pressure, guaranteeing durability and consistent performance. Our products incorporate a fire-safe design per API 607, anti-static devices, and blowout-proof stems, prioritizing workplace safety and fail-safe operation. Advanced sealing options including PTFE or graphite stem seals further enhance leak prevention under demanding operational conditions.

FAQ's of Metal Seated Ball Valve Manufacturer in Kheda:

Q: How are metal seated ball valves manufactured to achieve zero leakage?

A: Metal seated ball valves are precision engineered with tight metal-to-metal contact surfaces, ensuring they meet ISO 5208 Rate A zero leakage requirements. Each valve undergoes stringent testing at 1.5 times its rated pressure to confirm its sealing integrity and performance under extreme conditions.Q: What industries typically use these metal seated ball valves?

A: These valves are widely employed in sectors such as petrochemical, power generation, oil and gas, water treatment, and chemical processing due to their robustness and ability to handle aggressive fluids and high temperatures.Q: When should I opt for a metal-to-metal seat ball valve instead of a soft-seated one?

A: Choose metal-to-metal seat ball valves in applications involving abrasive media, extreme temperatures (ranging from -29C to +425C), or processes requiring superior resistance to wear, where soft seats might degrade quickly.Q: Where are your valves typically installed, and what connection options do you provide?

A: Our valves are installed in pipelines and process systems globally, utilizing end connections like butt weld, socket weld, threaded, or flanged as per ANSI, DIN, and BS standards. These options accommodate installation across various infrastructure and international requirements.Q: What is the process for selecting the correct metal seated ball valve for my application?

A: Selection involves assessing your media type (water, oil, gas, steam, chemicals), operating temperature and pressure, port size, end connection, and required safety features like fire-safe design or anti-static device. Our technical team can guide you through the process for optimal performance and safety.Q: How do the advanced coatings like PTFE or hard chrome plated ball enhance valve performance?

A: PTFE and hard chrome coatings increase corrosion and abrasion resistance, prolonging the lifespan of the ball valve even under harsh chemical and mechanical environments. This ensures reliable shut-off and minimal maintenance needs.Q: What are the benefits of using valves with full bore or reduced bore and 2-way or 3-way channel structures?

A: Full bore valves offer unobstructed flow, reducing pressure drop, while reduced bore options are suited for where space, flow rate, or cost considerations prevail. 2-way valves manage straightforward flows, while 3-way models facilitate mixing or diverting, offering versatility in process control.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Ball Valve Category

3 Way High Pressure Ball Manufacturer in Gandhidham

Price 2000 INR / Unit

Minimum Order Quantity : 1 Number

Media : Other, Water, Oil, Gas, Steam

Material : Stainless Steel

Application : Industrial / Chemical / Petrochemical / Power Plants

Finish : Polished

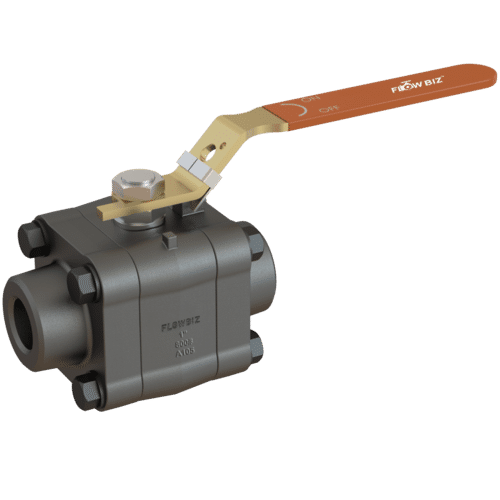

Forged Steel Ball Valve Manufacturer in Kheda

Price 800 INR / Unit

Minimum Order Quantity : 1 Number

Media : Other, Water, Oil, Gas

Material : Other, Forged Steel

Application : Industrial Pipelines, Chemical Plants, Refineries

Finish : AntiCorrosive Coating

Ball Valve Manufacturer in Sachin

Price 4000 INR / Unit

Minimum Order Quantity : 1 Number

Media : Other, Water, Gas, Oil

Material : Stainless Steel

Application : Industrial, Chemical, Water Treatment

Finish : Polished

Gear Operated Ball Valve

Price 4500 INR / Unit

Minimum Order Quantity : 1 Unit

Media : Gas

Material : Brass

Application : Industrial

Finish : Polished

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS