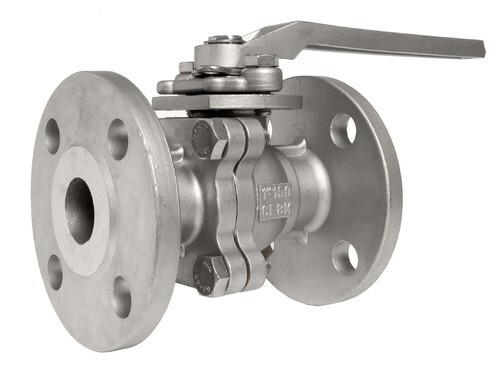

LnT Make Single Piece Design Ball Valve

Price 7000 INR/ Unit

LnT Make Single Piece Design Ball Valve Specification

- Caliber

- Full Bore

- Connection

- Screwed / Flanged

- Pressure

- Class 150/300, PN10/16

- Channels

- 2-way

- Structure

- Single Piece Body

- Material

- Carbon Steel / Stainless Steel / Brass

- Power

- Manual

- Media

- Water, Oil, Gas, Air, Steam

- Temperature of Media

- -20C to 180C

- Port Size

- 1/2 to 4

- Flange

- ANSI / DIN / IS

- Finish

- Epoxy Coated / Natural Finish

- Application

- Industrial, Chemical, Petrochemical, Water Treatment

- End Connection Standard

- BSP, NPT, Flanged

- Handle

- SS Lockable Lever

- Face to Face

- ASME B16.10

- Anti-Static Device

- Available

- Design Standard

- BS 5351 / API 6D

- Seat Material

- PTFE / RPTFE

- Blowout Proof Stem

- Provided

- Mounting

- Inline

- Leakage Class

- Class VI

- Testing Standard

- API 598

- Operation

- Quarter Turn

- Fire Safe Design

- Available as per API 607

About LnT Make Single Piece Design Ball Valve

L&T Series L1 Ball valves are single-piece flanged ball valves. Antistatic and fire safety, these valves have excelled in the industry by finding themselves in some of the most demanding applications.

- Catalogue no : L1RF1C / L1RF3C / L1FF1C / L1FF3C

- Material: Carbon Steel

- Catalogue no : L1RF1S/ L1RF3S / L1FF1S / L1FF3S

- Material: Stainless Steel

- Size range: 1/2 - 8

- Pressure rating: Class 150/300

- End connection: Flanged

Robust One-Piece Construction

Designed with a single piece body, this ball valve offers superior strength and reduced leakage risks. It handles pressures up to Class 300/PN16 and temperatures from -20C to 180C, making it ideal for demanding industrial, chemical, and petrochemical environments.

Versatile Operation and Safety Features

The quarter turn SS lockable lever gives straightforward manual control, while features such as fire-safe construction per API 607, blowout proof stem, and anti-static devices ensure uncompromising safety for operators and processes. The valve is suitable for inline mounting and 2-way channel operation.

Adaptability Across Applications

Supporting port sizes from 1/2 to 4 inches with full bore caliber, the valve can be connected using BSP, NPT, flanged, ANSI, DIN, or IS standards. This flexibility makes it a reliable choice for water treatment, petrochemical, chemical, and general industrial systems.

FAQ's of LnT Make Single Piece Design Ball Valve:

Q: How is the LnT Single Piece Design Ball Valve installed and operated?

A: This ball valve is installed inline using either screwed or flanged connections (BSP, NPT, ANSI, DIN, IS), and operated manually via a quarter turn SS lockable lever. Installation and operation are straightforward, following ASME B16.10 face-to-face and BS 5351/API 6D design standards.Q: What are the benefits of the fire-safe design and blowout proof stem?

A: The fire-safe design (API 607 compliant) increases safety by preventing leakage during fire incidents. The blowout proof stem adds another layer of operational security, ensuring the stem remains securely retained under extreme pressure or thermal conditions.Q: When should PTFE or RPTFE seat material be chosen for this valve?

A: PTFE or RPTFE seats are ideal for applications involving corrosive media, higher temperatures (up to 180C), or where low friction and tight sealing are critical. Selection depends on the media properties and specific environmental demands of your process.Q: Where can this ball valve be used effectively?

A: This valve is suitable for a wide range of environments, including industrial, chemical, petrochemical, and water treatment plants. Its robust construction, range of pressure ratings, and full bore flow make it apt for handling water, oil, gas, air, and steam.Q: What is the testing and quality assurance process for this ball valve?

A: Each valve undergoes rigorous testing as per API 598 standards to verify pressure, leakage, and operational reliability, ensuring consistent performance and compliance with international industry expectations.Q: How does the anti-static device enhance valve safety during usage?

A: The anti-static device prevents electrostatic build-up between the ball and stem, minimizing sparks that could ignite flammable media, thus safeguarding personnel and equipment during operation.Q: What are the advantages of selecting full bore and epoxy coated finish options?

A: Full bore design allows maximum flow with minimal pressure loss, while epoxy coated finishes enhance durability and resistance to corrosion, extending service life especially in harsh operating environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in L&T Ball Valve Category

LnT 3 Piece Ball Valve - Reduced Bore

Price 1500 INR / Unit

Minimum Order Quantity : 1 Number

Material : Casting

Media : Oil

Structure : Ball

Port Size : 15mm to 50mm

LnT Make IBR Ball Valve Energy Miser

Price 8000 INR / Unit

Minimum Order Quantity : 5

Material : Other, Forged Carbon Steel (ASTM A105), Stainless Steel (ASTM A182 Gr. F316/F304)

Media : Other, Steam, Water, Oil, Gas

Structure : Other, Floating Ball, Two Piece Design

Port Size : 15mm to 150mm ( to 6) nominal bore

LnT Make 2 Piece Design Ball Valve

Price 8000 INR / Unit

Minimum Order Quantity : 1 Number

Material : Other, Carbon Steel, Stainless Steel, Alloy Steel

Media : Other, Water, Oil, Gas, Steam

Structure : Other, 2 Piece Floating Ball

Port Size : 1/2 inch to 12 inch

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free