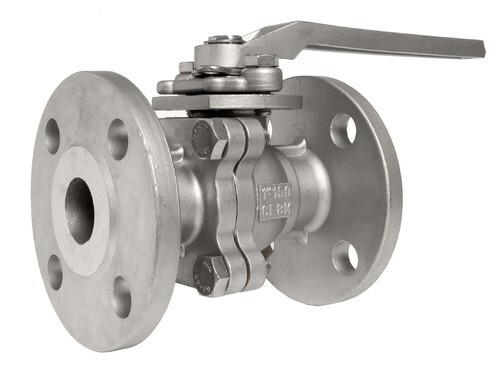

LnT Make IBR Ball Valve Energy Miser

Price 8000 INR/ Unit

LnT Make IBR Ball Valve Energy Miser Specification

- Pressure

- Up to 50 bar

- Structure

- Floating Ball, Two Piece Design

- Connection

- Flanged Ends as per ASME B16.5

- Caliber

- Full Bore/Reduced Bore

- Channels

- Two Way

- Material

- Forged Carbon Steel (ASTM A105), Stainless Steel (ASTM A182 Gr. F316/F304)

- Power

- Manual Operation

- Media

- Steam, Water, Oil, Gas

- Temperature of Media

- Up to 220C

- Port Size

- 15mm to 150mm ( to 6) nominal bore

- Flange

- Flanged End, Class 150/300

- Finish

- Shot blasted and corrosion resistant coating

- Application

- Steam and utility lines, condensate handling, process application

- Body Test Pressure

- 76 bar (Hydrostatic)

- Leakage Class

- CLASS VI

- Fire Safe Feature

- Yes

- Operation

- Lever Operated, Gear Operated (for large sizes)

- Product Type

- IBR Ball Valve Energy Miser

- Seat Test Pressure

- 56 bar (Hydrostatic)

- Size Range

- to 6

- Blowout Proof Design

- Yes, Antistatic Stem Design

- End Connection Standard

- ASME B16.5 / DIN / IS Standard

About LnT Make IBR Ball Valve Energy Miser

The Energy Miser is an IBR-certified valve that has revolutionized the concept of using ball valves for steam applications.

- Catalogue no : L6RBTC / L6RSWC / L6FBTC / L6FBWC

- Material: Carbon Steel

- Size range: 15mm to 50mm

- Pressure rating: CWP 69

- End connection: Screwed / Socket weld

Advanced Safety and Reliability

LnT IBR Ball Valve Energy Miser integrates a blowout-proof design, antistatic stem, and fire-safe features, ensuring maximum safety in demanding environments. These engineering enhancements protect against unexpected valve failures and static discharge, making the valve suitable for critical utility and process applications.

Versatile Application and Performance

With compatibility for steam, water, oil, and gas, and a temperature threshold of 220C, this valve is ideal for a wide range of industrial uses. Its two-way channel, floating ball, and two-piece configuration ensure precise and efficient media control, supporting process integrity across high-pressure systems.

Quality Materials and Durability

Manufactured using forged carbon steel and stainless steel options, the valve is shot blasted and finished with corrosion-resistant coatings. These quality materials guarantee longevity, reliability, and resistance to aggressive media encountered in industrial utility and condensate handling operations.

FAQ's of LnT Make IBR Ball Valve Energy Miser:

Q: How is the LnT IBR Ball Valve Energy Miser operated?

A: The valve can be operated manually using a lever for standard sizes or a gear mechanism for larger sizes, allowing smooth and safe operation in various installations.Q: What types of media can this ball valve handle?

A: It is designed for use with steam, water, oil, and gas, making it suitable for a diverse array of industrial and utility applications.Q: When should full bore or reduced bore valves be used?

A: Full bore valves are preferred when minimal flow restriction and easier pipeline cleaning are needed, while reduced bore valves are ideal when space or flow optimization is a consideration with compatible processes.Q: Where can the LnT IBR Ball Valve Energy Miser be installed?

A: It is meant for installation on steam and utility lines, condensate handling systems, and various process pipelines in industries such as power generation, chemical processing, and oil and gas.Q: What process conditions can this valve withstand?

A: The valve is suitable for operations up to 50 bar pressure and media temperatures reaching 220C, accommodating rigorous hydrostatic pressure tests and meeting ASME B16.5 standards.Q: How does the fire-safe and antistatic stem design benefit users?

A: The fire-safe feature helps maintain sealing integrity during fire incidents, and the antistatic stem design prevents static buildup, improving safety for facilities handling flammable media.Q: What are the main benefits of choosing the LnT IBR Ball Valve Energy Miser?

A: Key benefits include high reliability, robust safety features, corrosion resistance, precise flow control, and compliance with global standards, delivering long-term value across critical process and utility applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in L&T Ball Valve Category

LnT 3 Piece Ball Valve - Reduced Bore

Price 1500 INR / Unit

Minimum Order Quantity : 1 Number

Structure : Ball

Pressure : High Pressure

Temperature of Media : 180 Deg C Celsius (oC)

Media : Oil

LnT Make 2 Piece Design Ball Valve

Price 8000 INR / Unit

Minimum Order Quantity : 1 Number

Structure : Other, 2 Piece Floating Ball

Pressure : Other, Class 150 to Class 600

Temperature of Media : 20C to 200C

Media : Other, Water, Oil, Gas, Steam

LnT Make Single Piece Design Ball Valve

Price 7000 INR / Unit

Minimum Order Quantity : 5

Structure : Other, Single Piece Body

Pressure : Other, Class 150/300, PN10/16

Temperature of Media : 20C to 180C

Media : Other, Water, Oil, Gas, Air, Steam

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS