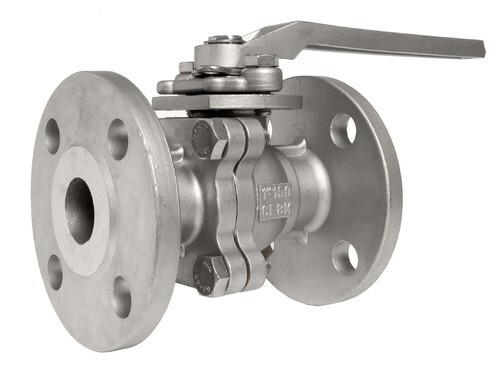

LnT Make 2 Piece Design Ball Valve

Price 8000 INR/ Unit

LnT Make 2 Piece Design Ball Valve Specification

- Structure

- 2 Piece Floating Ball

- Channels

- Single Channel

- Caliber

- Full Bore

- Pressure

- Class 150 to Class 600

- Connection

- Flanged / Screwed / Socket Weld

- Material

- Carbon Steel, Stainless Steel, Alloy Steel

- Power

- Manual/Lever Operated

- Media

- Water, Oil, Gas, Steam

- Temperature of Media

- -20C to 200C

- Port Size

- 1/2 inch to 12 inch

- Flange

- ANSI, DIN, IS & Custom Standards

- Finish

- Anti-corrosive Painted / Stainless Steel Natural

- Application

- Industrial, Chemical, Petrochemical, Water Treatment, Oil & Gas

- Leakage Class

- Class VI / Bubble-tight

- Operation Type

- Quarter Turn

- End Type

- Flanged / Threaded / Socket Weld

- Fire Safe Design

- Available

- Working Temperature Range

- -20°C to +200°C

- Mounting Standard

- ISO 5211 for Actuation

- Body Design

- Two-piece

- Face to Face Dimension

- As per ASME B16.10 / IS 11792

- Blowout Proof Stem

- Provided

- Valve Size Range

- ½ inch to 12 inch

- Stem Material

- Stainless Steel

- Ball Material

- Chrome Plated / Stainless Steel

- Seat Material

- PTFE, RPTFE, Metal Seated

- Testing Standard

- API 598 / BS EN 12266

About LnT Make 2 Piece Design Ball Valve

2 Piece Design Ball Valve Flanged End

- Catalogue no : L2FF1C / L2FF3C

- Material: Carbon Steel

- Catalogue no : L2FF1S / L2FF3S

- Material: Stainless Steel

- Size range: 15mm to 200mm

- Pressure rating: Class 150# / 300#

- End connection: Flanged

Versatile Valve Design

LnT's 2 Piece Design Ball Valve adapts to different connection requirements including flanged, screwed, or socket weld ends. With a full bore and single channel structure, it assures optimal flow with minimal pressure drop, making it suitable for various industries such as chemical, petrochemical, and oil & gas.

Robust Materials and Construction

The valve is constructed using carbon steel, stainless steel, or alloy steel, featuring a chrome plated or stainless steel ball and stainless steel stem. Its anti-corrosive finish and metal or PTFE seats assure durability and performance even in challenging environments.

Enhanced Safety and Compliance

Equipped with a blowout proof stem and fire safe design, this ball valve conforms to API 598 and BS EN 12266 testing standards, ensuring high safety and leak-proof operation. The bubble-tight, Class VI leakage design meets stringent industry needs.

FAQ's of LnT Make 2 Piece Design Ball Valve:

Q: How is the LnT 2 Piece Design Ball Valve installed in a pipeline?

A: The valve can be installed using flanged, threaded, or socket weld ends, accommodating various pipeline layouts. The face-to-face dimensions align with ASME B16.10 or IS 11792 standards for straightforward integration.Q: What applications are best suited for this ball valve?

A: This valve is ideal for industrial, chemical, petrochemical, oil & gas, and water treatment applications due to its robust construction, full bore flow, and compatibility with water, oil, gas, and steam across a temperature range of -20C to +200C.Q: When should the different seat materials (PTFE, RPTFE, metal) be chosen?

A: PTFE and RPTFE seats are preferred for chemical resistance and temperature stability, while metal seats are suitable for abrasive services or higher temperatures, enhancing longevity and reliability in demanding applications.Q: Where are these ball valves manufactured and exported from?

A: LnT Make 2 Piece Design Ball Valves are manufactured in India and supplied to global and domestic markets, serving a wide array of industries with reliable quality and performance.Q: What is the process for operating this ball valve?

A: The valve is operated manually via a lever, offering a quick quarter-turn action (90) between open and closed positions for effective isolation and flow control in pipelines.Q: How does the fire safe and blowout proof design benefit users?

A: The fire safe features ensure the valve maintains sealing capability in fire conditions, while the blowout proof stem design enhances safety by preventing stem ejection under pressure, safeguarding both processes and personnel.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in L&T Ball Valve Category

LnT 3 Piece Ball Valve - Reduced Bore

Price 1500 INR / Unit

Minimum Order Quantity : 1 Number

Material : Casting

Pressure : High Pressure

Port Size : 15mm to 50mm

Media : Oil

LnT Make Single Piece Design Ball Valve

Price 7000 INR / Unit

Minimum Order Quantity : 5

Material : Other, Carbon Steel / Stainless Steel / Brass

Pressure : Other, Class 150/300, PN10/16

Port Size : 1/2 to 4

Media : Other, Water, Oil, Gas, Air, Steam

LnT Make IBR Ball Valve Energy Miser

Price 8000 INR / Unit

Minimum Order Quantity : 5

Material : Other, Forged Carbon Steel (ASTM A105), Stainless Steel (ASTM A182 Gr. F316/F304)

Pressure : Other, Up to 50 bar

Port Size : 15mm to 150mm ( to 6) nominal bore

Media : Other, Steam, Water, Oil, Gas

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free