Lift Check Valve Manufacturer in Vadodara

Price 2000 INR/ Unit

Lift Check Valve Manufacturer in Vadodara Specification

- Application

- Process Industries like-Chemical, Power, Refinery, Petrochemicals, Nuclear, Water

- Type

- Manual

- Media

- Water

- Port Size

- Customized as per requirement

- Temperature

- Up to 200C Celsius (oC)

- Disc

- SS 304

About Lift Check Valve Manufacturer in Vadodara

Key Features

We are:

- An instrumental company for manufacturing. Exporting and supplying a vast array of valve from Pune, Maharashtra.

- India.

Our range of products offered is widely praised by our customers all around the nation. Available in diverse sizes that suit the needs of our customers.

Minimum Order Quantity: 1 Piece

Media: Air, Gas, Liquid

Brand: FlowBiz

Type: Check Valve

Sizes (inch): 2 to 24 (dn-50 to dn-600)

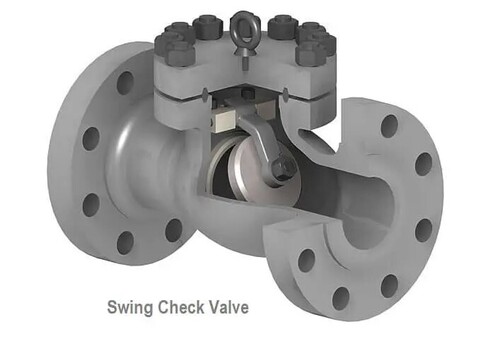

Pattern: Swing

Lift Check Valves Advantages:

Longer life

Withstand high pressure

Rust resistance

Tailored Solutions for Industrial Applications

Our lift check valves meet the diverse needs of process industries, offering customized port sizes and robust SS 304 disc construction. Whether you require solutions for chemical plants, power stations, or refineries, we provide reliable and efficient valve systems designed to ensure safety and optimized flow control.

Superior Quality and Performance

With manual operation and engineered to perform with water media at temperatures up to 200C, our lift check valves stand out for their durability and consistent performance. Every valve undergoes strict quality checks, ensuring compliance with industry standards and providing dependable protection against backflow in critical operations.

FAQ's of Lift Check Valve Manufacturer in Vadodara:

Q: How are lift check valves used in process industries?

A: Lift check valves are installed in pipelines to prevent backflow, protecting equipment and maintaining unidirectional flow. In process industries like chemical and power plants, these valves are crucial for ensuring operational safety and integrity by automatically closing if reverse flow occurs.Q: What makes your lift check valves suitable for high-temperature applications?

A: Our valves are designed to withstand media temperatures up to 200C, using SS 304 for the disc, which offers excellent resistance to corrosion and heat. This makes them ideal for industries where processes involve elevated temperatures and aggressive flow conditions.Q: When should a lift check valve be used instead of other types?

A: A lift check valve is generally preferred when you need a simple, reliable solution for vertical or horizontal flow lines, especially in systems where quick closure and minimal leakage are essential. Its design is particularly effective for water and compatible fluids used in process industries.Q: Where is manufacturing and supply of these valves carried out?

A: We manufacture lift check valves in Vadodara, India, and supply them as exporters, manufacturers, suppliers, and traders to clients nationwide and internationally. Our facility is equipped to meet the specific requirements of various industrial applications.Q: What is the process for customizing port size and specifications?

A: Clients can specify their required port sizes and operational parameters during the inquiry or ordering phase. Our engineering team collaborates closely with customers to deliver valves customized for their exact process needs, ensuring compatibility and optimized performance.Q: How does manual operation benefit valve usage?

A: Manual operation provides precise control during installation, maintenance, or emergency conditions, enabling users to inspect or isolate sections of the pipeline efficiently. This feature makes lift check valves adaptable and user-friendly in complex industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Check Valve Category

Tilting Disc Check Valves

Price 5000 INR / Unit

Minimum Order Quantity : 1 Number

Application : Industrial piping systems, water treatment, oil & gas, chemical processing, power plants

Disc : Onepiece disc, streamlined design for low pressure drop

Media : Other, Water, oil, gas, steam, chemicals

Temperature : 20C to 425C (depending on material)

Lift Check Valve Manufacturer in Jamnagar

Price 800 INR / Unit

Minimum Order Quantity : 1 Number

Application : industrial

Lift Check Valve Manufacturer in Gandhidham

Price 2000 INR / Unit

Minimum Order Quantity : 1 Number

Application : Process Industries likeChemical, Power, Refinery, Petrochemicals, Nuclear, Water

Disc : SS 304

Media : Water

Temperature : Up to 200C Celsius (oC)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free