Tilting Disc Check Valves

Price 5000 INR/ Unit

Tilting Disc Check Valves Specification

- Connection Type

- Wafer, Lug, or Flanged Ends

- Features

- Low pressure drop, quick closing, minimal slam effect, maintenance friendly

- Valve Size

- 2 to 48 (DN50 to DN1200)

- Valve Type

- Check valve / Non-return valve

- Material

- Body: Cast Iron, Ductile Iron, Carbon Steel, Stainless Steel, Alloy Steel; Disc: Stainless Steel, Alloy steel or equivalent

- Application

- Industrial piping systems, water treatment, oil & gas, chemical processing, power plants

- Structure

- Tilting disc, single disc, wafer or flanged body

- Sealing

- Metal to metal or soft-seated (Nitrile/EPDM/Viton options)

- Type

- Tilting disc check valve

- Power

- Manual (Non-actuated)

- Pressure

- Class 150 to Class 2500 (PN10-PN420)

- Media

- Water, oil, gas, steam, chemicals

- Port Size

- DN 50 to DN 1200

- Temperature

- -20C to 425C (depending on material)

- Disc

- One-piece disc, streamlined design for low pressure drop

- Pin

- Single pivot pin

- Bonnet Type

- Bolted bonnet

- Coating

- Fusion bonded epoxy (for select models)

- End Connection Standard

- ANSI, DIN, JIS, BS

- Testing Pressure

- As per API 598 or EN 12266

- Flow Direction

- Unidirectional

- Gasket Material

- Graphite, PTFE, or as specified

- Leakage Class

- API 598

- Face to Face Dimensions

- ASME B16.10 or manufacturer standard

- Standard Conformance

- API 594, BS 1868, ASME B16.34

- Installation Position

- Horizontal or vertical (upward flow)

About Tilting Disc Check Valves

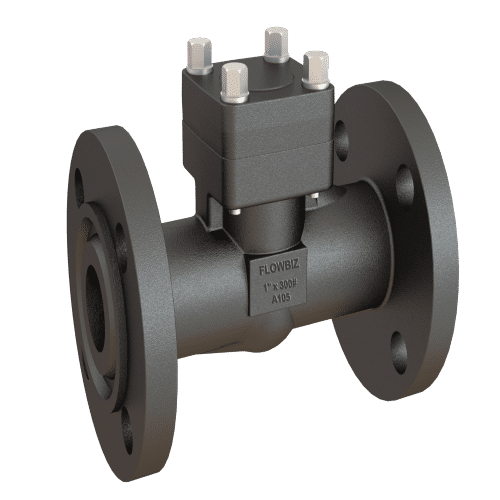

FlowBiz Exports Pvt Ltd Valves is a High Quality Tilting Disc Check Valves Manufacturer in Mumbai, Maharashtra, India. We are a leading manufacturer of Tilting Disc Check Valves in Mumbai and nearby areas.

Tilting Disc Check Valves are often forgotten by many industry experts. However, Tilting Disc Check Valves are one of the most important Valves in a system. They work to ensure smooth operations and safety. But what is a Tilting Disc Check Valves and how does it work? A Tilting Disc Check valve, clack valve, non-return valve, reflux valve, retention Valves or one-way Valves is a Valves that normally allows fluid (liquid or gas) to flow through it in only one direction.

Tilting Disc Check Valves are two-port valves, meaning they have two openings, one for fluid to enter and the other for fluid to leave. There are various types of Tilting Disc Check Valves used in a wide variety of applications. Tilting Disc Check Valves are often used for common household items. Although FlowBiz Exports Pvt Ltds Tilting Disc Check Valves are available in a wide range of sizes and costs, they are generally very small, simple, or inexpensive. Tilting Disc Check Valves work automatically and most are not controlled by a person or any external control.

Features:

Metal or soft seated options.

Renewable nickel alloy seat.

Integral elastomeric seat.

Variety of flange configurations.

Spring loaded hinge.

External spring adjustment.

Product Details:

Brand: FlowBiz

Size - 2.5" - 24"

Pressure Class - ANSI 150

Design - ASME B16.34

End connection - ASME B 16.5

Test - API 598

Material - CF8,CF8(Ti), CF8M, CG8M, CN7M(Alloy 20), WCC, LCC

Reliable Flow Control Across Industries

Tilting Disc Check Valves are a trusted choice for applications requiring effective prevention of reverse flow. Their streamlined design delivers low pressure drop, rapid response, and impressive durability. Suitable for both horizontal and vertical (upward flow) installation, these valves accommodate a wide range of media, including water, oil, gas, steam, and chemicalsfor industries as diverse as power generation, oil & gas, and processing plants.

Engineered for Strict Standards and Longevity

Built to conform with API 594, BS 1868, and ASME B16.34, these valves exceed rigorous quality and safety benchmarks. Leak tightness is assured via API 598 testing. Materials such as graphite and PTFE gaskets and a choice of sealing options accommodate demanding operating conditions from -20C to 425C. An optional fusion bonded epoxy coating adds an extra layer of protection against corrosion and aggressive environments.

FAQs of Tilting Disc Check Valves:

Q: How does a tilting disc check valve prevent reverse flow in piping systems?

A: A tilting disc check valve operates using a single-disc mechanism that pivots open with forward flow and closes quickly when reverse flow occurs. This design ensures unidirectional flow, preventing backflow and protecting pumps and system integrity.Q: What installation positions are suitable for these check valves?

A: These valves are designed for flexible installation and can be mounted in both horizontal or vertical (upward flow) positions, depending on the direction of process flow and specific application requirements.Q: When should I choose a metal-to-metal versus soft-seated valve?

A: Metal-to-metal seats are ideal for high-temperature or abrasive media, offering superior durability. Soft-seated options (Nitrile, EPDM, or Viton) are best for applications needing bubble-tight shutoff or handling corrosive fluids at lower temperatures.Q: Where are tilting disc check valves commonly used?

A: They are widely used in industrial sectors like water treatment, oil & gas, chemical processing, and power plants, where reliable backflow prevention is essential for operational safety and equipment protection.Q: What benefits does the tilting disc design provide compared to conventional swing check valves?

A: The tilting disc design offers a lower pressure drop, quicker closure to prevent slam effects, and higher reliability. It also provides easier maintenance due to the single-pivot mechanism and simpler structure.Q: How are these valves tested and what standards do they conform to?

A: Tilting disc check valves are pressure tested according to API 598 or EN 12266 standards, confirming their leak tightness and structural integrity. They also conform to international standards like API 594, BS 1868, and ASME B16.34, ensuring suitability for global projects.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Check Valve Category

Non-Slam Disc Check Valve Manufacturer in India

Price 2500 INR / Unit

Minimum Order Quantity : 1 Number

Features : Nonslam closing, Corrosion resistant, Low pressure drop, Maintenance free

Material : CF8, CF8M, WCB, Cast Iron, Ductile Iron

Power : Other, Manual (Nonpowered operation)

Control System : Selfactuated

Swing Flex Check Valves

Price 4500 INR / Unit

Minimum Order Quantity : 1 Number

Features : Lowpressure drop, nonslam, selfclosing, easy installation, maintenance free, corrosion resistant

Material : Body: Ductile Iron (ENGJS45010)

Power : Other, Manual/automatic (nonelectric, flowoperated)

Control System : Flowcontrolled, springless

Lift Check Valve Manufacturer in Rajkot

Price 500 INR / Unit

Minimum Order Quantity : 1 Number

Features : Corrosion resistant, Low maintenance, Leak proof design

Material : Cast Iron, Cast Steel, SS304, SS316

Power : Other, Manual (Nonpowered)

Control System : Self actuated

Swing Check Valve Manufacturer in India

Price 4400 INR / Unit

Minimum Order Quantity : 1 Number

Features : Corrosion Resistant, Leak Proof, Durable Construction, Bolted Cover, Wafer/Flanged End

Material : Cast Iron, Cast Steel, Stainless Steel, Bronze, Ductile Iron

Power : Manual

Control System : Manual Non Return Flow

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free