Lift Check Valve Manufacturer in Rajkot

Price 500 INR/ Unit

Lift Check Valve Manufacturer in Rajkot Specification

- Control System

- Self actuated

- Material

- Cast Iron, Cast Steel, SS304, SS316

- Connection Type

- Flanged / Screwed

- Valve Size

- inch to 8 inch

- Features

- Corrosion resistant, Low maintenance, Leak proof design

- Valve Type

- Lift Check Valve

- Sealing

- PTFE / Metal to Metal

- Structure

- Lift Type Check Valve

- Application

- Industrial pipeline systems, water supply, chemical processing, oil & gas refineries

- Type

- Flanged End, Screwed End

- Power

- Manual (Non-powered)

- Pressure

- Up to PN40

- Media

- Water, Oil, Steam, Air, Gas

- Port Size

- DN15 to DN200

- Temperature

- Up to 220C

- Disc

- Stainless Steel / Brass / Bronze

- Pin

- 304 Stainless Steel

- Installation Orientation

- Horizontal & Vertical

- Testing

- Hydrostatic & pneumatic tested

- MOC Variant

- Available in CI, CS, SS grades

- Packing

- Standard export packaging

- Working Medium

- Liquid, Gas, Steam

- Design Pressure

- Up to 40 Bar

- End Connection

- Customizable as per requirement

- Max Flow Rate

- Customized as per size

- Surface Finish

- Smooth and polished

- Standard

- ANSI, DIN, BS, IS certified

About Lift Check Valve Manufacturer in Rajkot

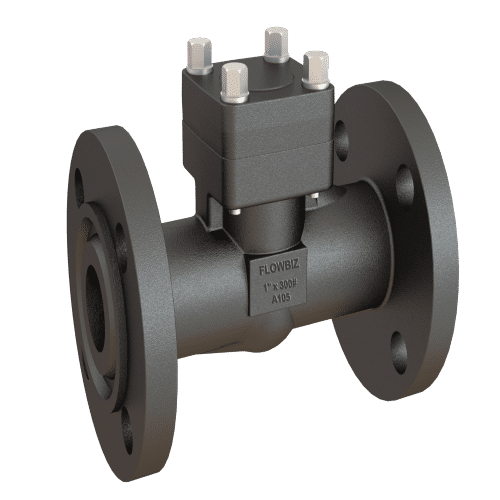

FlOWBIZ FORGED STEEL CHECK VALVE FLANGE END

FORGED STEEL CHECK VALVE FLANGE END - ASA 150 CLASS

Standards & Specifications :

Design Standard : API 602 / BSEN ISO 15761

Type : Lift / Piston Check Valve Bolted / Weld Cover

Full Bore, Weld-On Flanges

FORGED STEEL CHECK VALVE FLANGE END - ASA 300 CLASS

Standards & Specifications:

Design Standard : API 602 / BSEN ISO 15761

Type : Lift / Piston Check Valve Bolted / Weld Cover

Full Bore, Weld-On Flanges

FORGED STEEL CHECK VALVE FLANGE END - ASA 600 CLASS

Standards & Specifications:

Design Standard : API 602 / BSEN ISO 15761

Type : Lift / Piston Check Valve Bolted / Weld Cover

Full Bore, Weld-On Flanges

FORGED STEEL CHECK VALVE SCREWED END, SOCKET & BUTT WELD END - ASA 800 CLASS

Standard & Specifications:

Design Standard : API 602 / BSEN ISO 15761

Type : Lift / Piston Check Valve Bolted / Weld Cover

FORGED STEEL CHECK VALVE SCREWED END, SOCKET & BUTT WELD END - ASA 1500 CLASS

Standard & Specifications:

Design Standard : API 602 / BSEN ISO 15761

Type : Lift / Piston Check Valve Bolted / Weld Cover

FORGED STEEL CHECK VALVE SCREWED END, SOCKET & BUTT WELD END - ASA 2500 CLASS

Standard & Specifications:

Design Standard : API 602 / BSEN ISO 15761

Type : Lift / Piston Check Valve Bolted / Weld Cover

Engineered for Versatility and Performance

Our lift check valves are designed to meet diverse industrial needs, accommodating different media such as liquids, gases, and steam. With a robust construction available in cast iron, cast steel, and stainless steel grades, every valve undergoes stringent hydrostatic and pneumatic testing for reliable sealing and performance. Flexible installation options (horizontal or vertical) and customizable ends-flanged or screwed-make integration into a wide range of systems seamless and efficient.

Quality Assured, Certified Manufacturing

All valves are manufactured under strict adherence to international standards such as ANSI, DIN, BS, and IS. Our quality control ensures each valve meets certifications and undergoes comprehensive testing to provide dependable service with minimal maintenance. Surface finishes are smooth and polished for enhanced corrosion resistance, guaranteeing longevity and optimal operation in harsh environments.

Tailored Solutions for Specialized Applications

With customizable port sizes (from 12 inch to 8 inch) and a selection of seating and disc materials (PTFE or metal-to-metal, stainless steel, brass, or bronze), our valves deliver precision control for specialized applications. Whether for industrial pipelines, water supply networks, chemical processing, or oil & gas refineries, our products are built for efficiency, leak prevention, and long service life.

FAQ's of Lift Check Valve Manufacturer in Rajkot:

Q: How do I select the right lift check valve size and material for my application?

A: Choosing the correct size and material depends on your system's medium (water, steam, oil, gas), required design pressure (up to 40 bar), temperature (up to 220C), and compatibility with pipeline specifications. Materials like cast iron, steel, or stainless steel are available based on corrosion resistance needs. Our team can assist with custom sizing (12 inch to 8 inch or DN15 to DN200) to match your requirements.Q: What are the testing standards followed for these lift check valves?

A: All our lift check valves are hydrostatic and pneumatic tested in compliance with ANSI, DIN, BS, and IS standards. This rigorous testing ensures each valve is leak proof and reliable, ready to operate in demanding industrial environments.Q: When should a lift check valve be installed horizontally versus vertically?

A: A lift check valve can be installed in both horizontal and vertical orientations. For upward flow (vertical installation), ensure the medium flow direction matches the valve's design. Horizontal installation is commonly used for stable, continuous flows. Always follow installation guidelines for optimal performance and longevity.Q: Where can these lift check valves be used?

A: Our lift check valves are suitable for industrial pipeline systems, water supply networks, chemical processing plants, oil & gas refineries, and any application requiring dependable backflow prevention and pressure retention.Q: What is the benefit of corrosion-resistant and low maintenance features?

A: Corrosion resistance, achieved through quality materials and polished finishes, prolongs valve life and ensures consistent operation even in harsh media. Low-maintenance design reduces downtime and operational costs, providing value for long-term industrial use.Q: How is the valve's performance customized for varying flow rates and pressures?

A: We offer customization for max flow rates and design pressure (up to 40 bar) depending on your system size and application. Our engineering team will collaborate to configure port size, end connections, and sealing types, ensuring optimal performance tailored to your operational needs.Q: What is the process for ordering and receiving a customized lift check valve?

A: Contact us with your specifications-media type, pressure, temperature, port size, end connection, and material preferences. We will guide you through design selection, manufacturing, and testing, and provide standard export packaging for secure worldwide delivery.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Check Valve Category

Check Valve Function

Price 2400 INR / Unit

Minimum Order Quantity : 1 Number

Type : NonReturn Check Valve

Application : Industrial and Fluid Handling Systems

Port Size : 1 inch to 12 inch (Standard Range)

Media : Other, Liquid, Gas, Air

Swing Flex Check Valves

Price 4500 INR / Unit

Minimum Order Quantity : 1 Number

Type : Swing Flex Check Valve

Application : Suitable for potable water, sewage, wastewater, fire protection, and industrial applications.

Port Size : DN50DN600 (224)

Media : Other, Water, sewage, noncorrosive fluids

Check Valve Piston Type Manufacturer in India

Price 2500 INR / Unit

Minimum Order Quantity : 1 Number

Non-Slam Disc Check Valve Manufacturer in Rajkot

Price 600 INR / Unit

Minimum Order Quantity : 1 Number

Type : Manual

Application : Process Industries likeChemical, Power, Refinery, Petrochemicals, Nuclear, Water

Port Size : Customized as per requirement

Media : Water

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS