Check Valve Function

Price 2400 INR/ Unit

Check Valve Function Specification

- Valve Size

- DN25 to DN300

- Material

- Cast Iron/Carbon Steel/Stainless Steel Body

- Valve Type

- Flanged/Screwed Check Valve

- Control System

- Self-Activated by Flow Direction

- Connection Type

- Flanged Ends/Threaded Ends

- Features

- Low Pressure Drop, Prevents Backflow, Easy Installation, Maintenance-Free

- Voltage

- Not Applicable (Manual Operation)

- Application

- Industrial and Fluid Handling Systems

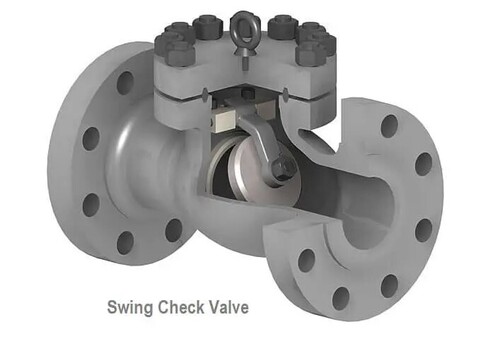

- Structure

- Swing Type Body

- Sealing

- EPDM or NBR Seal

- Type

- Non-Return Check Valve

- Power

- Manual / Non-powered

- Pressure

- up to 16 Bar

- Media

- Liquid, Gas, Air

- Port Size

- 1 inch to 12 inch (Standard Range)

- Temperature

- -10C to 100C

- Disc

- High Quality Rubber Coated or Metal Disc

- Pin

- Stainless Steel Pin

- Body Design

- Full Bore Construction

- Leakage Rate

- Tight Shut Off

- Service Life

- Long Service Life with Minimum Wear

- Operation Mode

- Automatic via Flow Reversal

- Application Industry

- Water Supply, Wastewater Treatment, Chemical Plants, Oil & Gas

- Flow Direction

- Unidirectional

- Body Coating

- Anti-Corrosion Coated

- Installation Position

- Horizontal & Vertical

About Check Valve Function

The function of the FlowBiz check valve is only to allow the medium to flow in one direction and prevent the flow in multiple directions. Usually, the FlowBiz check valve functions automatically. Under the action of the fluid pressure flowing in one direction, the disc opens; when the fluid flows in the opposite direction, the disc acts on the valve seat due to the self-coincidence of the fluid pressure and the disc, thereby cutting off the flow.

Our check valve is standard in control applications to ensure that the flow of liquid or gas is in only one direction. To complete this function, check valves usually have two ports: one for fluid to enter and the other for fluid exit.

Automatic Flow Reversal Operation

The check valve operates automatically to prevent backflow and ensure the flow moves in only one direction. Its swing type design, powered by fluid movement rather than electricity or manual effort, makes it ideal for industrial settings where reliability and efficiency are paramount.

Full Bore Construction with Anti-Corrosion Protection

Built with full bore construction and coated with anti-corrosion materials, the valve provides low pressure drop and excellent durability. The robust body options-cast iron, carbon steel, or stainless steel-ensure compatibility with a variety of aggressive fluids and harsh environmental conditions.

Flexible Installation and Maintenance-Free Design

This check valve supports both horizontal and vertical installation positions, facilitating seamless integration into new or existing systems. With its maintenance-free operation and tight shut off, users enjoy reduced downtime and operational costs.

FAQ's of Check Valve Function:

Q: How does the check valve operate automatically without external power?

A: The check valve relies on flow reversal in the pipeline to trigger the swing-type disc, allowing fluid to flow in only one direction. When flow reverses, the disc closes, preventing backflow-all without any external power source or manual intervention.Q: What types of media can this check valve handle effectively?

A: This valve is designed for versatility, accommodating liquids, gases, and air. Its robust seals and anti-corrosion coated body make it suitable for water supply, chemical processes, wastewater treatment, and oil & gas applications.Q: When should I use a full bore, swing type non-return check valve?

A: Full bore, swing type check valves are recommended where low pressure drop, long service life, and reliable backflow prevention are critical, especially in industrial fluid handling systems and pipeline networks across various sectors.Q: Where can the check valve be installed in a system?

A: This valve supports both horizontal and vertical installation, making it adaptable for different piping layouts and system requirements. Installation is straightforward due to flanged or threaded ends and its maintenance-free construction.Q: What is the process of maintaining this check valve?

A: Thanks to its anti-corrosion coating, high-quality materials, and tight shut off design, this valve is maintenance-free under normal operating conditions, reducing service costs and minimizing downtime.Q: How does the valve benefit industrial fluid handling applications?

A: By preventing backflow, offering easy installation, and operating without manual or electric controls, the valve enhances system efficiency, safety, and longevity across applications like water supply, chemical processing, and wastewater management.Q: What is the advantage of EPDM or NBR seals in this valve?

A: EPDM and NBR seals provide excellent chemical resistance and ensure tight shut off, accommodating a wide range of operating temperatures and pressures for reliable performance in various media.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Check Valve Category

2/2 Way Miniature Low Flow Proportional Valve

Price 3200 INR / Number

Minimum Order Quantity : 1 Unit

Type : 2/2 Way Miniature Low Flow Proportional Valve

Temperature : 0C to 50C

Application : Low flow fluid control in medical devices, analytical instruments, and laboratory automation

Port Size : M5 / 1/8 NPT (custom options available)

Swing Check Valve in Mumbai

Price 1800 INR / Unit

Minimum Order Quantity : 1 Number

Type : Swing Check Valve

Temperature : 10C to +180C

Application : Industrial Use, Water, Oil, Steam, Gas

Port Size : DN 15 mm to 300 mm

Check Valve Wafer Type Manufacturer in India

Price 2500 INR / Unit

Minimum Order Quantity : 1 Number

Type : Manual

Temperature : Up to 200C Celsius (oC)

Application : Process Industries likeChemical, Power, Refinery, Petrochemicals, Nuclear, Water

Port Size : Customized as per requirement

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free