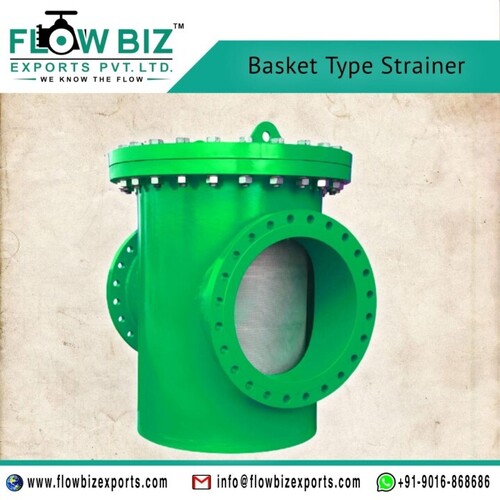

Basket Type Strainer Manufacturer in Vapi

Price 2000 INR/ Unit

Basket Type Strainer Manufacturer in Vapi Specification

- Application

- Process Industries like-Chemical, Power, Refinery, Petrochemicals, Nuclear, Water

- Type

- Manual

- Media

- Water

- Port Size

- Customized as per requirement

- Temperature

- Up to 200°C Celsius (oC)

- Disc

- SS 304

About Basket Type Strainer Manufacturer in Vapi

FlowBiz Export Pvt Ltd specializes in the manufacturing of basket-type strainers. A basket-type strainer is vital in various industrial processes to remove unwanted particles and debris from fluids. It is designed to provide efficient filtration by capturing solid contaminants that could potentially damage or clog downstream equipment.

Key Features of Basket Type Strainer:

- Filtration Efficiency

- Easy Maintenance

- Material Options

- Pressure Drop Considerations

- Size and Configuration Options

- Durable Construction

- Basket Design

Precision Filtration for Critical Applications

Our basket type strainers deliver reliable solids removal in industrial water processes. Crafted from high-grade SS 304, they promise durability and corrosion resistance in harsh environments. Suitable for a variety of demanding industries, our strainers support operational continuity and protect vital equipment downstream.

Customizable to Suit Diverse Needs

We design and manufacture strainers with port sizes tailored to your specific requirements. Whether retrofitting existing systems or installing new lines, our team collaborates with you to achieve optimal fit and performance, assuring seamless integration into your facility's workflow.

FAQ's of Basket Type Strainer Manufacturer in Vapi:

Q: How is a basket type strainer installed and maintained?

A: Basket type strainers are installed inline within the pipeline. The manual design allows easy removal of the basket for cleaning or replacement. Routine inspection and maintenance help prevent clogging and ensure consistent filtration performance.Q: What industries benefit most from your basket type strainers?

A: Our basket type strainers are ideal for process industries, notably chemical, power, refinery, petrochemical, nuclear, and water treatment facilities, where robust, reliable water filtration is essential for smooth operations.Q: When should I consider customizing the port size for my application?

A: Custom port sizes are recommended when standard options do not fit your pipeline dimensions or specific process requirements. Customization ensures a secure fit, optimized flow, and better protection for your downstream equipment.Q: Where are your basket type strainers manufactured and exported from?

A: Our basket type strainers are manufactured in Vapi, India. We export and supply these products both within India and to international clients, supporting a wide range of industrial operations globally.Q: What is the process for selecting the right basket type strainer for my facility?

A: Selecting the right strainer involves evaluating media compatibility, required filtration level, port sizing, temperature conditions, and application needs. Our technical experts provide guidance to ensure you receive the most suitable solution for your process.Q: How does the SS 304 disc enhance the strainer's performance?

A: SS 304 is chosen for its excellent corrosion resistance and mechanical strength, especially in contact with water and various chemicals. This ensures that the strainer delivers long-term durability and minimizes maintenance frequency.Q: What are the key benefits of using your basket type strainers?

A: Key benefits include superior solids removal, reduced equipment wear, extended system lifespan, customizable configurations, high-temperature capability, and straightforward manual operation. These advantages collectively help minimize downtime and maximize process reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in strainer Category

Pot Strainer Manufacturer in Vadodara

Price 1700 INR / Unit

Minimum Order Quantity : 1 Number

Media : Other, Water, oil, chemicals, gases

Application : Liquid and gas flow systems, chemical processing, water treatment, industrial pipelines

Temperature : Up to 220°C

Features : Corrosion resistant, easy maintenance, high dirt holding

Basket Strainer Manufacturer in Gandhidham

Price 2000 INR / Unit

Minimum Order Quantity : 1 Number

Media : Other

Features : Best Quality

Duplex Strainer Manufacturer in Jamnagar

Price 700 INR / Number

Minimum Order Quantity : 1 Number

Features : Good Quality

Duplex Strainers Manufacturer in Pune

Price 1500 INR / Unit

Minimum Order Quantity : 1 Number

Media : Water

Application : Process Industries likeChemical, Power, Refinery, Petrochemicals, Nuclear, Water

Temperature : Up to 200°C Celsius (oC)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free