Basket Strainer Manufacturer in Gandhidham

Price 2000 INR/ Unit

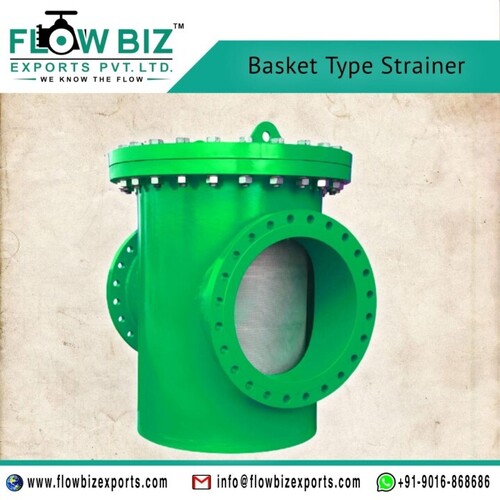

Basket Strainer Manufacturer in Gandhidham Specification

- Features

- Best Quality

- Control System

- PLC

- Material

- Cast Iron

- Usage

- Pipelines Carrying Liquids, Gases, Or Steam.

- Power

- Manual

- Size

- 1/2 inch to 24 inch

- Pressure

- Other PSI

- Media

- Other

- Color

- Green

About Basket Strainer Manufacturer in Gandhidham

Basket strainersare the type of strainers bigger than theY-type strainers. Simplex basket strainers can be cast and fabricated depending on various factors. The shape of simplex basket strainers is like a basket that can store large amounts of debris. Also, the bigger size provides a proper platform for an effective filtration area. Although the weight of simplex basket strainers is quite heavy, its enormous size renders excellent capacity for holding dirt.

Acasted simplex basket straineris a strainer made up of robust cast It has a threaded drain, and the fluids flow inside and outside. Providing strainer expertise, we offer various physical and technical feature options, which can be selected per our clients preferences.

Size:"- 2" ( Screwed, Socket weld)

Size:"- 16" (Flanged ends, Butt weld ends)

Rating:150#

Advanced Filtration for Industrial Pipelines

Basket strainers play a crucial role in protecting valuable equipment by filtering out unwanted debris from liquids, gases, or steam within pipelines. Constructed from cast iron, these strainers ensure durability and resistance to corrosion. The green-colored finish enhances identification, while manual operation combined with PLC control provides precise and safe functionality for various industrial applications.

Versatile Sizing for Broad Applications

Available in sizes from 1/2 inch to 24 inch, our basket strainers cater to a wide range of pipeline systems. This flexibility allows industries to select the perfect fit for their specific fluid or gas flow requirements, ensuring optimal performance and longevity of pipeline infrastructure.

FAQs of Basket Strainer Manufacturer in Gandhidham:

Q: How is the basket strainer installed in pipelines carrying liquids, gases, or steam?

A: The basket strainer is designed for easy installation in pipeline systems ranging from 1/2 inch to 24 inch diameter. It is manually fitted into the pipeline at points where filtration is needed, ensuring contaminants are trapped before reaching sensitive equipment.Q: What materials are used for manufacturing the basket strainers, and why is cast iron preferred?

A: Our basket strainers are constructed from premium cast iron, known for its strength and corrosion resistance. This material ensures longevity and reliable performance in industrial environments handling various fluids and gases.Q: When should a basket strainer be used in industrial processing systems?

A: A basket strainer should be installed whenever pipelines transport liquids, gases, or steam that may contain particulates or debris, protecting pumps, valves, and other equipment from clogging and damage.Q: Where are these basket strainers manufactured and supplied from?

A: Our basket strainers are manufactured in Gandhidham, India, and are supplied, exported, and traded to clients nationally and internationally through our well-established distribution channels.Q: What is the process for maintaining and cleaning the basket strainer?

A: Regular maintenance involves manually opening the strainer body, removing the basket, and cleaning out trapped particles. The PLC control system helps monitor operation and schedule cleaning cycles, ensuring uninterrupted performance.Q: How does the basket strainer benefit pipeline operations in industries?

A: Basket strainers enhance pipeline efficiency by preventing debris from entering critical components, reducing wear and maintenance costs, and ensuring smooth operation of fluid, gas, or steam systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in strainer Category

Y Type Strainer Manufacturer in Gandhidham

Price 1500 INR / Unit

Minimum Order Quantity : 1 Number

Application : Water, Oil & Gas Industries, Chemical Processing, Petrochemical Industries

Media : Other, Gas, Water, Oil, Air

Type : Y Type Strainer

Material : Cast Iron, Cast Steel, Stainless Steel (SS304/SS316)

Y Strainer Manufacturer in Pune

Price 1500 INR / Unit

Minimum Order Quantity : 1 Number

Application : Industrial filtration, pipeline protection, water treatment plants, HVAC systems, chemical and oil processing industries

Media : Other, Water, Steam, Gas, Oil and other fluids

Type : Y Strainer

Material : Cast Iron, Carbon Steel, Stainless Steel (SS304/SS316), Bronze

Y Type Strainer Manufacturer in Gandhinagar

Price 1000 INR / Unit

Minimum Order Quantity : 1 Number

Material : MS

Strainer Manufacturer in Jamnagar

Price 500 INR / Unit

Minimum Order Quantity : 1 Number

Application : industrial

Media : Gas, Base, Water

Type : Strainer

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free