Y Type Strainer Manufacturer in Gandhidham

Price 1500 INR/ Unit

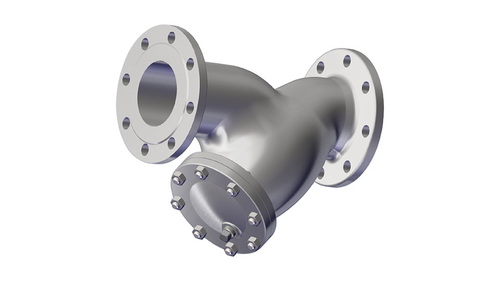

Y Type Strainer Manufacturer in Gandhidham Specification

- Valve Type

- Strainer

- Connection Type

- Flanged / Screwed

- Control System

- Manual

- Material

- Cast Iron, Cast Steel, Stainless Steel (SS304/SS316)

- Features

- Low Maintenance, Rust Resistance, Durable Construction

- Valve Size

- 1/2 inch to 12 inch

- Structure

- Y Type

- Sealing

- PTFE / Metal to Metal

- Application

- Water, Oil & Gas Industries, Chemical Processing, Petrochemical Industries

- Type

- Y Type Strainer

- Power

- Manual

- Pressure

- Up to 40 Bar

- Media

- Gas, Water, Oil, Air

- Port Size

- 15mm to 300mm

- Temperature

- Up to 220C

- Disc

- SS Perforated Screen

- Pin

- Stainless Steel

- Body Test Pressure

- As per IS 2825/ASME Sec VIII

- Hydrostatic Test Pressure

- 1.5 x Working Pressure

- Installation Position

- Horizontal/Vertical

- End Connection

- Screwed, Flanged, Socket Weld

- Coating

- Epoxy Coated

- Mesh Size

- 40 Mesh to 400 Mesh

- Screen Retention

- Bolted Cover

About Y Type Strainer Manufacturer in Gandhidham

FlowBiz Export Private Limited, based in Pune, is a renowned manufacturer and exporter of Y Type Strainers. The company is committed to excellence and has proved itself as a trusted provider of high-quality filtration keys in India and beyond. Here are some reasons why FlowBiz stands out in the market.

Material: Stainless Steel

Size>24 inch

Media: air water oil gas steam

End Connection: Flange End, Butt Weld, Screwed End

Pressure: 0-10 bar

Connection Standard: screwed flange butt weld

Lined Material: ss304,316

Material Grade: ss brass ci

Type: y-type

Specifications:

- Power: Hydraulic

- Material: Casting

- Pressure: Low Pressure

Robust Construction and Versatile Connections

Our Y Type Strainers feature a rugged structure made from high-grade materials such as Cast Iron, Cast Steel, and Stainless Steel (SS304/SS316). Available connection types include flanged, screwed, and socket weld, ensuring compatibility with diverse pipeline arrangements. These strainers are manually controlled, making them reliable and easy to operate in both new installations and retrofit projects.

Precision Filtration for Critical Applications

Equipped with a bolted cover for secure screen retention, our Y Type Strainers provide filtration mesh sizes from 40 mesh up to 400 mesh. The PTFE or metal-to-metal sealing ensures minimal leakage, while the SS perforated screen and stainless steel pin guarantee durability in demanding environments. Their robust design supports applications in water, oil, gas, chemical processing, and petrochemical industries.

Tested Performance and Easy Maintenance

Each unit undergoes rigorous hydrostatic and body pressure testing as per IS 2825/ASME Sec VIII, ensuring safety and reliability under pressures up to 40 Bar. With epoxy coating for added rust resistance and simple screen cleaning/replacement enabled by the bolted cover, our strainers are designed for long-lasting, low-maintenance service life.

FAQ's of Y Type Strainer Manufacturer in Gandhidham:

Q: How does a Y Type Strainer work in industrial pipelines?

A: A Y Type Strainer operates by mechanically removing unwanted solids from the flow of liquids or gases in a pipeline. The medium passes through a perforated or mesh-lined straining element (screen), which traps debris, ensuring smooth process flow and protecting downstream equipment from damage.Q: What is the recommended installation orientation for these strainers?

A: Our Y Type Strainers can be installed in either horizontal or vertical positions, providing flexibility for various pipeline configurations and space constraints. Follow manufacturer guidelines to ensure the screen is positioned correctly for optimal performance.Q: When should the strainer screen be cleaned or replaced?

A: Screen cleaning or replacement depends on the level of contamination in the media and frequency of use. Generally, regular inspection is recommended, especially in processes prone to high debris. The bolted cover design makes maintenance quick and efficient.Q: Where are these Y Type Strainers commonly used?

A: These strainers are widely employed across water, oil & gas industries, chemical processing plants, petrochemical facilities, and other applications requiring protection from particulate contamination. They are suitable for use with water, oil, gas, and air media.Q: What is the process for hydrostatic and body pressure testing?

A: Each strainer undergoes a hydrostatic test at 1.5 times the working pressure and a body test as per IS 2825 or ASME Sec VIII. This process verifies the integrity and leak resistance of the strainer before shipment.Q: Which benefits do these Y Type Strainers offer to industries?

A: Industries benefit from these strainers through efficient particulate removal, extended equipment lifespan, minimal maintenance requirements, and enhanced pipeline reliability. Their robust, rust-resistant construction ensures long-term service even under challenging operating conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in strainer Category

T Type Strainer Manufacturer in Gandhinagar

Price 1200 INR / Unit

Minimum Order Quantity : 1 Number

Material : Carbon Steel / Stainless Steel (SS304, SS316)

Features : Corrosion Resistant, Easy Maintenance, High Filtration Efficiency, Robust Construction

Structure : Other, TType Body Design

Power : Other, Manual Operation

Y Type Strainer Manufacturer in Vapi

Price 1200 INR / Unit

Minimum Order Quantity : 1 Number

Material : Cast Iron, Cast Steel, Stainless Steel, Bronze

Features : Corrosion resistant, Heavy duty, Easy maintenance

Structure : Other, Y Type

Power : Manual

Strainer Manufacturer In Narmada

Price 5000 INR / Unit

Minimum Order Quantity : 1 Number

Material : Cast Iron, Carbon Steel, Stainless Steel, Bronze

Features : Corrosion Resistant, Compact Design, Easy Maintenance, High Dirt Holding Capacity

Structure : Other, YType, TType, Basket Type

Power : Manual

Strainer Valve Manufacturers in Gandhinagar

Price 800 INR / Unit

Minimum Order Quantity : 1 Number

Material : SS

Features : Good Quality

Structure : Control

Power : Manual

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free