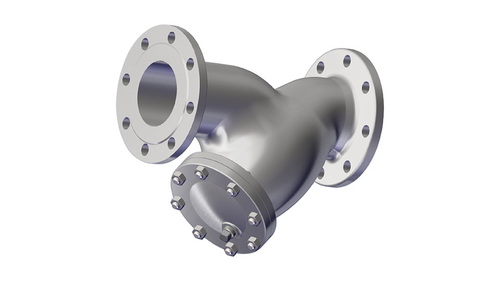

Y Strainer Manufacturer in Pune

Price 1500 INR/ Unit

Y Strainer Manufacturer in Pune Specification

- Valve Type

- Strainer

- Valve Size

- 1/2 to 12 (DN15 to DN300)

- Connection Type

- Flanged, Screwed (BSP/NPT), Socket Weld

- Control System

- Manual

- Material

- Cast Iron, Carbon Steel, Stainless Steel (SS304/SS316), Bronze

- Features

- Corrosion-resistant, easy maintenance, quick cleaning, durable body

- Sealing

- Gasket / O-Ring sealing between body and cover

- Application

- Industrial filtration, pipeline protection, water treatment plants, HVAC systems, chemical and oil processing industries

- Structure

- Body - Y-shaped with mesh filter element

- Type

- Y Strainer

- Power

- Not applicable (No power required for operation)

- Pressure

- Up to 40 bar (PN16, PN25, PN40)

- Media

- Port Size

- 15 mm to 300 mm (1/2 to 12) or as per requirement

- Temperature

- Up to 300C / Customer specified

- Disc

- Perforated or mesh stainless steel filter

- Optional Accessories

- Drain Plug / Blow-off Connection

- Flow Direction

- Horizontal / Vertical

- Working Life

- Long Service Life

- End Connection Standard

- ANSI, DIN, IS

- Cleaning

- Screen can be removed for cleaning

- Gasket Material

- PTFE / EPDM / Graphite

- Painting / Coating

- Epoxy Coated

- Design Standard

- BS EN 558-1

- Test Pressure

- Hydro Tested up to 24 Bar

- Screen Type

- SS316 Mesh / Perforation as per requirement

About Y Strainer Manufacturer in Pune

FlowBiz Export Private Limited,based in Pune, is a renowned manufacturer and exporter of Y Type Strainers. The company is committed to excellence and has proved itself as a trusted provider of high-quality filtration keys in India and beyond. Here are some reasons why FlowBiz stands out in the market.

Material: Stainless Steel

Size>24 inch

Media: air water oil gas steam

End Connection: Flange End, Butt Weld, Screwed End

Pressure: 0-10 bar

Connection Standard: screwed flange butt weld

Lined Material: ss304,316

Material Grade: ss brass ci

Type: y-type

Specifications:

- Power:Hydraulic

- Material:Casting

- Pressure:Low Pressure

Superior Industrial Filtration Solutions

Our Y strainers are designed to deliver exceptional protection for pipelines and critical equipment in water treatment plants, HVAC systems, chemical and oil processing industries. The robust construction and premium stainless steel mesh ensure effective removal of particulate matter, thereby enhancing system performance and minimizing downtime.

Flexible Installation & Durable Construction

Engineered for both horizontal and vertical flows, our strainers support multiple end connection standards, offering seamless integration into new and existing pipelines. The durable epoxy-coated body and high-quality gasket materials, including PTFE, EPDM, and graphite, provide resistance against corrosion and extended operational life under demanding conditions.

Convenient Maintenance and User-Friendly Design

Routine maintenance is effortless thanks to the easily removable stainless steel screen. Additional accessories such as drain plugs and blow-off connections support quick cleaning, minimizing operational disruption. With manual control and simple gasket/O-ring sealing, operation remains efficient and reliable, with no power requirement.

FAQs of Y Strainer Manufacturer in Pune:

Q: How does the Y strainer remove impurities from pipelines?

A: The Y strainer features a stainless steel mesh or perforated filter element placed inside its Y-shaped body, which traps and removes debris, particles, and impurities from fluids passing through. This helps protect downstream equipment and ensures smooth operation.Q: What are the recommended cleaning procedures for the strainer screen?

A: To clean the strainer, simply unscrew the body cover and remove the SS316 mesh or perforated screen. Rinse or brush off trapped debris, then reassemble. Accessories like a drain plug or blow-off connection can also assist in periodic maintenance, ensuring efficient operation.Q: When is it advisable to use a Y strainer in industrial applications?

A: Y strainers are best employed during initial pipeline setup or routine system upgrades in water treatment plants, HVAC systems, and chemical processing to safeguard equipment from particles that might cause clogging or damage.Q: Where can these strainers be installed?

A: These Y strainers can be installed in both horizontal and vertical pipeline orientations. They are suitable for water, steam, gas, oil, and various other fluids across multiple industries, in accordance with end connection and design standards like ANSI, DIN, and IS.Q: What are the main benefits of using an epoxy-coated Y strainer with removable screen?

A: Epoxy coating extends the life of the strainer body by providing excellent corrosion resistance. The removable screen feature allows for quick and convenient cleaning, reducing downtime and maintenance costs while maintaining high filtration efficiency.Q: How does the strainer accommodate different operating pressures and temperatures?

A: Our Y strainers are hydro-tested up to 24 bar and available for pressures up to 40 bar (PN16, PN25, PN40). They are constructed with quality materials to withstand operating temperatures up to 300C or as per customer specifications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in strainer Category

Y Type Strainer Manufacturer in Gandhidham

Price 1500 INR / Unit

Minimum Order Quantity : 1 Number

Material : Cast Iron, Cast Steel, Stainless Steel (SS304/SS316)

Features : Low Maintenance, Rust Resistance, Durable Construction

Structure : Other, Y Type

Media : Other, Gas, Water, Oil, Air

Y Type Strainer Manufacturer in Kheda

Price 1000 INR / Unit

Minimum Order Quantity : 1 Number

Material : Cast Iron, Cast Steel, Stainless Steel, Bronze

Features : Corrosion resistant, Easy maintenance, High durability

Structure : Other, Y Type Body

Media : Other, Liquids, Gases, Steam

Pot Type Strainer Manufacturer in India

Price 4000 INR / Unit

Minimum Order Quantity : 1 Number

Material : Cast Iron, Stainless Steel, Carbon Steel

Features : Removable Screen, High Dirt Retention, Low Pressure Drop

Structure : Other, Pot Type

Media : Other, Water, Oil, Steam, Gas

Strainer Valve Manufacturers in Gandhinagar

Price 800 INR / Unit

Minimum Order Quantity : 1 Number

Material : SS

Features : Good Quality

Structure : Control

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free