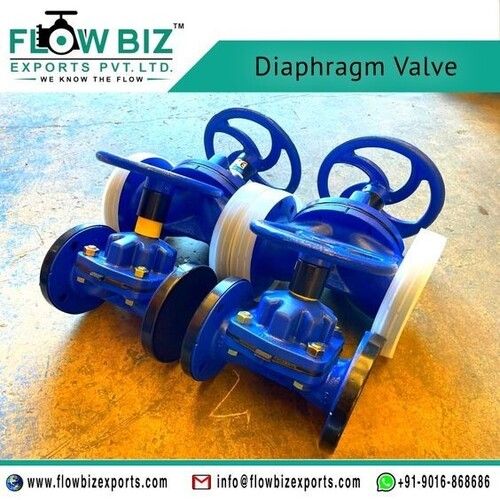

Weir Type Diaphragm Valve

Price 5000 INR/ Unit

Weir Type Diaphragm Valve Specification

- Application

- Chemical, Water Treatment, Pharmaceutical, Food Processing, Mining, Effluent Handling

- Size

- DN15 to DN300

- Voltage

- Electric Actuator: 220V / 380V

- Color

- Blue / Black / Customized

- Connection

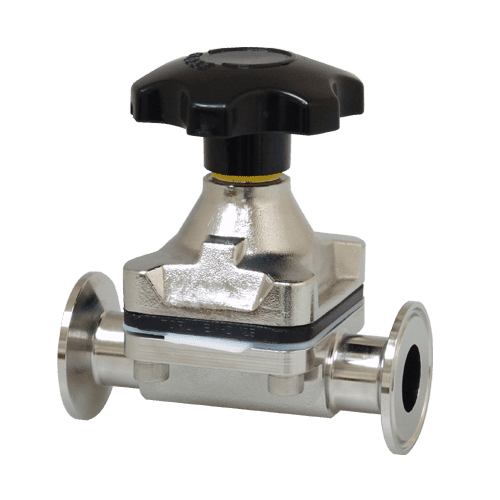

- Flanged / Screwed / Tri-clover

- Pressure

- PN10 / PN16 / Class 150

- Type

- Weir Type Diaphragm Valve

- Material

- Cast Iron / Stainless Steel / Ductile Iron / PVC (as per requirement)

- Temperature

- -10C to 120C (material dependent)

- Media

- Water, Chemicals, Gases, Slurry, Oils

- Standard

- DIN / BS / ANSI / IS

- Power

- Manual / Pneumatic / Electric

- Port Size

- 15mm to 300mm

- Model

- Weir Type Diaphragm Valve

- Characteristics

- Corrosion Resistant, Leak Proof, Bubble Tight Closure

- Face to Face Dimension

- As per DIN/BS/IS Standard

- Bonnet Material

- Cast Iron / Stainless Steel

- Seat Type

- Integral / Replaceable

- Operation

- Handwheel, Pneumatic Actuator, Electric Actuator

- Body Lining

- Rubber Lined / Unlined

- End Connection Standard

- EN 1092, ASME B16.5, IS 1538

- Diaphragm Material

- EPDM / PTFE / Neoprene / Rubber

- Inspection and Testing

- As per API 598 / BS 6755

- Leakage Class

- Class VI (Bubble Tight)

About Weir Type Diaphragm Valve

FlowBiz Exports Pvt Ltd Valves is a High Quality Diaphragm Valves Manufacturer in Mumbai, Maharashtra, India. We are a leading manufacturer of Weir Type Diaphragm Valve in Mumbai and nearby areas.

Diaphragm Valves consists of a Valves body with two or more ports, a diaphragm, and a "weir or saddle" or seat upon which the Diaphragm closes the valve. The basic construction of the Diaphragm Valves is quite simple. It is composed of three principal units called Body, Bonnet and Diaphragm.

Diaphragm Valves are particularly designed for handling Corrosive, Abrasives, Viscous or Fibrous Fluids.

Specifications:

Valve Body MOC: Ebonite lined CI/PTFE lined CI/PFA lined CI/CS/SS

Application: On-Off Application

Diaphragm MOC: EPDM/PTFE

Operation: manual operated / spring return diaphragm actuated

Product Details:

Size -15 mm to 350 mm

Media - Water

Pressure - Medium Pressure

Operating Air Pressure- 50-57 psig

Control Valve Closing Time - 8-10 Sec

Versatile Material Options

Weir Type Diaphragm Valves are offered with bonnet and body materials such as cast iron, stainless steel, ductile iron, and PVC to meet various application requirements. Diaphragm selections-EPDM, PTFE, neoprene, and rubber-provide impressive chemical compatibility and temperature resistance, making them suitable for many industrial processes.

Precise and Leak-Free Performance

With Class VI (bubble tight) leakage certification and integral or replaceable seat types, these valves guarantee a superior leak-proof seal. Rubber lining is available for enhanced corrosion resistance. Conforming to EN 1092, ASME B16.5, and IS 1538, the valves maintain stringent international connection standards for reliability and easy integration.

Flexible Operation and Control

Operation can be tailored for manual, pneumatic, or electric actuation, suiting both remote and on-site management scenarios. Electric actuators come in 220V or 380V. The wide port size (15mm to 300mm) range and customizable colors offer adaptability for varied industrial settings, ensuring easy maintenance and optimal process control.

FAQ's of Weir Type Diaphragm Valve:

Q: How is the Weir Type Diaphragm Valve operated?

A: The valve can be operated manually with a handwheel or automatically using pneumatic or electric actuators. Electric actuators are available in 220V and 380V options, allowing for both on-site and remote control depending on system requirements.Q: What materials are used for the body, bonnet, and diaphragm of this valve?

A: Body and bonnet materials include cast iron, stainless steel, ductile iron, and PVC (as required). Diaphragms can be supplied in EPDM, PTFE, neoprene, or rubber, chosen based on chemical compatibility and the intended application's temperature range.Q: When should I use a rubber lined vs. unlined valve body?

A: A rubber lined valve is recommended when handling corrosive media or abrasive slurries, providing extra durability and protection. Unlined bodies are suitable for less aggressive fluids and applications where lining is unnecessary.Q: Where are Weir Type Diaphragm Valves typically used?

A: These valves are widely used in chemical plants, water and wastewater treatment, pharmaceuticals, food processing, mining, and effluent handling due to their robust construction and compatibility with a wide range of fluids.Q: What is the process for selecting the correct diaphragm material?

A: Selection depends on fluid characteristics, operating temperature (-10C to 120C), and chemical compatibility. For aggressive chemicals, PTFE is preferred; for water or general fluids, EPDM or rubber may be used. Technical consultation can help determine optimal material selection.Q: What are the benefits of using this valve in industrial applications?

A: The valve provides reliable, leak-proof shut-off (Class VI bubble tight closure), high resistance to corrosion, and flexibility in connection and operation types. Its compliance with international standards ensures easy integration and consistent, dependable performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Diaphragm Valve Category

PTFE Lined Diaphragm Valve Manufacturer in Pune

Price 700.00 INR / Unit

Minimum Order Quantity : 1 Number

Material : Cast Iron

Color : Blue

Size : 1/2" to 12"

Usage : Industrial

SS Diaphragm Valve Manufacturer in Kheda

Price 800 INR / Unit

Minimum Order Quantity : 1 Number

Material : Stainless Steel

Color : Black

Size : All size

Usage : Construction

Diaphragm Valve Manufacturer in Jamnagar

Price 800 INR / Unit

Minimum Order Quantity : 1 Number

Material : Stainless Steel

Color : Blue

Size : All size

SS Diaphragm Valve Manufacturer in Rajkot

Price 500 INR / Unit

Minimum Order Quantity : 1 Number

Material : Stainless Steel

Color : Silver

Size : Standard Sizes

Usage : Industrial

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free