Strainer Manufacturers in Vapi

Price 3700 INR/ Unit

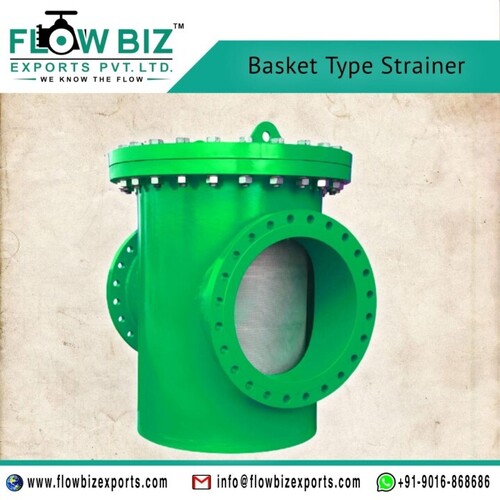

Strainer Manufacturers in Vapi Specification

- Connection Type

- Threaded / Flanged

- Features

- Corrosion Resistant, Durable

- Material

- Cast Iron / Stainless Steel

- Valve Type

- Screwed End

- Control System

- Manual

- Valve Size

- 1/2 to 12

- Application

- Industrial Filtration

- Structure

- Y Type

- Sealing

- Gasket

- Voltage

- 220 V

- Type

- Strainer

- Power

- Manual

- Pressure

- 16 Bar

- Media

- Water, Oil, Gas

- Port Size

- 20 mm

- Temperature

- 80C

- Disc

- Stainless Steel Mesh

- Pin

- 2 Pin

- Maintenance

- Easy Removal and Cleaning

- Shape

- Y / Basket / T-Type

- Coating

- Epoxy Painted / Hot Dip Galvanized

- Mesh Size

- 10 to 300 Micron

- Design Standard

- ASME, DIN, BS

- End Connection

- Threaded, Flanged, Socket Weld

About Strainer Manufacturers in Vapi

Strainersare essential components in industrial filtration, playing a key role in maintaining the integrity of various processes and equipment across industries. These modest devices are designed to remove unwanted particles, debris, and contaminants from flowing liquids or gases, ensuring critical systems smooth operation and longevity.FlowBizstrainers are available in various typeY-type strainers, T-type strainers, basket strainers, duplex basket strainers, and temporary/conical strainers.

FlowBiz is the best manufacturer ofStrainersin India. We supplyStrainersin Ahmedabad, Vapi, Valsad, Surat, Gandhidham, Kutch, Ankleshwar, Bharuch, Mumbai, Nashik, Pune, Thane, Aurangabad, Satara, Sangli, Nagpur, Kolhapur, Indore, Dewas, Bhopal, Chennai, Coimbatore, Selam and all over India.

Precision Filtration Solutions

Our strainers deliver reliable filtration for industrial applications, trapping particles as fine as 10 microns and as large as 300 microns. Designed for critical applications in water, oil, and gas processes, they support effective contaminant removal while maintaining optimal fluid flow. The epoxy and hot-dip galvanized coatings enhance service life in harsh environments.

Robust Design Meets Global Standards

Crafted from high-grade materials, our strainers feature leak-proof gaskets and stainless steel mesh discs. Every product adheres to global design standards such as ASME, DIN, and BS, ensuring consistent quality and compatibility for export and domestic markets alike.

Ease of Maintenance and Operation

Prioritizing user convenience, our strainers are designed for swift removal and cleaning, minimizing downtime. Their manual operation allows precise control, and the versatile end connections (threaded, flanged, socket weld) ensure seamless installation across various system configurations.

FAQs of Strainer Manufacturers in Vapi:

Q: How do I select the right mesh size for my industrial filtration needs?

A: Selecting the mesh size depends on the particle size you aim to filter. A mesh size of 10 to 300 microns accommodates a wide range of industrial applications, from removing fine debris in water treatment to larger particles in oil and gas processes.Q: What is the cleaning and maintenance process for these strainers?

A: Our strainers are engineered for easy removal and cleaning. Regular maintenance involves shutting down the line, removing the strainer cover, extracting the basket or screen, and flushing out accumulated particles. The gasket ensures secure resealing after reassembly.Q: When should I consider using a Y-type versus a basket or T-type strainer?

A: Y-type strainers suit continuous or high-pressure operations with minimal debris, while basket or T-type designs are ideal for handling higher volumes of particulates or when frequent cleaning is required. Selection depends on your specific flow and maintenance requirements.Q: Where can these strainers be installed within my industrial system?

A: These strainers can be installed at the inlet of pumps or critical process equipment to intercept and retain particulates. The threaded, flanged, or socket weld connections offer flexibility, allowing placement in various pipeline systems in water, oil, or gas applications.Q: What are the benefits of epoxy painted or hot dip galvanized coatings?

A: Epoxy painted and hot dip galvanized coatings substantially increase protection against corrosion and chemical exposure, extending the strainers lifespan even in demanding industrial settings.Q: How does the manual operation and control system function?

A: The manual valve and control system provide direct, reliable adjustment over fluid flow. This simple design ensures consistent performance with minimal maintenance, reducing the risk of mechanical failure.Q: What international standards do your strainers comply with?

A: Our products meet leading international standards such as ASME, DIN, and BS, guaranteeing high quality, safety, and compatibility for both domestic use and export to various global markets.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in strainer Category

Conical Strainer Manufacturer in Vapi

Price 2500 INR / Unit

Minimum Order Quantity : 1 Number

Features : Easy cleaning, high durability, corrosion resistant

Media : Other, Liquid, Gas

Material : Stainless Steel SS304, SS316, Carbon Steel

Basket Strainer Manufacturer in Gandhidham

Price 2000 INR / Unit

Minimum Order Quantity : 1 Number

Color : Green

Features : Best Quality

Media : Other

Material : Cast Iron

T Strainer Manufacturer in Surat

Price 3000 INR / Unit

Minimum Order Quantity : 1 Number

Color : Blue

Features : Good Quality

Material : MS

Basket Type Strainer Manufacturer in Gandhinagar

Price 800 INR / Unit

Minimum Order Quantity : 1 Number

Color : Blue

Features : Good Quality

Material : MS

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free