Strainer Manufacturers in Mumbai

Price 2000 INR/ Unit

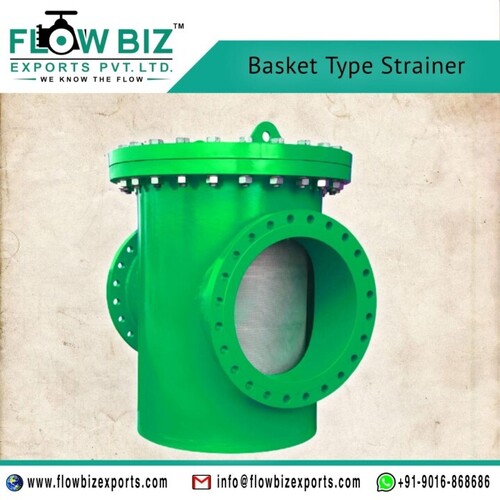

Strainer Manufacturers in Mumbai Specification

- Material

- Cast Iron, Carbon Steel, Stainless Steel (304, 316, 316L), Bronze

- Valve Type

- Manual, Automatic (Self-cleaning options available)

- Connection Type

- Flanged, Screwed (BSP/NPT), Socket weld, Butt weld

- Features

- Easy maintenance, High-strength body, Leak-proof design, Corrosion-resistant finish, Efficient filtration

- Valve Size

- 1/2 to 24 (DN15 to DN600)

- Control System

- Manual or motorized for self-cleaning strainer types

- Application

- Industrial, Commercial, Water treatment plants, Chemical processing, Oil & Gas, Pharmaceuticals

- Structure

- Y-Type, T-Type, Basket-Type, Duplex

- Sealing

- EPDM, PTFE, NBR, Graphite, Metal-to-metal depending on application

- Type

- Y-Strainer, Basket Strainer, Duplex Strainer, T-Type Strainer

- Power

- Not applicable (Mechanical device)

- Pressure

- Up to 40 bar (Design pressure; varies by model and material)

- Media

- Water, Air, Gas, Steam, Oil, Chemicals

- Port Size

- 15mm to 600mm (Standard and customized sizes)

- Temperature

- -10C to 400C (Depending on material and design)

- Disc

- Perforated sheet or wire mesh (Stainless Steel, Monel, Hastelloy)

- Screen Type

- Perforated, Mesh, Wedge Wire

- Drain Plug

- Provided for Easy Cleaning

- Mesh Size Range

- 10 Mesh to 500 Mesh

- Coating

- Epoxy or Hot-Dip Galvanized

- Body Test Pressure

- Hydro tested at 1.5 times Design Pressure

- Flow Rate Capacity

- As per Client Requirement

- End Connection Standard

- ANSI, DIN, BS

- Flow Direction

- Unidirectional

About Strainer Manufacturers in Mumbai

FlowBiz Export Private Limited:

Setting the Standard in Y Type StrainersFlowBiz Export Private Limited, based in Nashik, is a renowned manufacturer and exporter of Y Type Strainers. The company is committed to excellence and has proved itself as a trusted provider of high-quality filtration solutions in India and beyond. Here are some reasons why FlowBiz stands out in the market:

Expertise and Experience:

FlowBiz boasts a team of experienced engineers and technicians with in-depth filtration system knowledge. With years of experience, they understand the intricacies of Y Type Strainers and their applications across various industries.

Customized Solutions:

FlowBiz recognizes that each industry and application has unique requirements. Therefore, they offer customized solutions tailored to meet specific customer needs. FlowBiz can deliver Y Type Strainers that align with the clients specifications, whether its a particular size, material, or mesh type.

High-Quality Manufacturing:

FlowBiz maintains stringent quality control measures at every stage of the manufacturing process. They utilize advanced machinery, cutting-edge technology, and premium-grade materials to ensure their Y Type Strainers meet international quality standards. This commitment to quality guarantees reliable and durable products.

Wide Range of Applications:

Y Type Strainers find applications in various industries, including oil and gas, petrochemicals, water treatment, pharmaceuticals, food processing, etc. FlowBiz understands the diverse needs of these industries and offers Y Type Strainers suitable for different fluids, pressures, and temperatures.

Timely Delivery and Customer Support:

FlowBiz prioritizes customer satisfaction and ensures timely delivery of orders. They have an efficient supply chain management system to meet deadlines without compromising quality. Moreover, their dedicated customer support team is always ready to assist clients with their queries and concerns.

Versatile Strainer Types and Customization

Our Mumbai-based manufacturing facilities provide Y-Type, T-Type, Basket-Type, and Duplex Strainers, available in various sizes (15mm600mm). We offer adaptability with flanged, screwed, socket weld, and butt weld connections. Strainers can be customized to meet specific client requirements, accommodating diverse industrial and commercial settings.

High Strength and Leak-Proof Design

All strainers undergo stringent hydro testing at 1.5 times their design pressure to ensure reliability and safety in operation. Advanced coatings, including epoxy or hot-dip galvanization, coupled with stainless steel or specialty alloy meshes, deliver exceptional durability and corrosion resistance, ensuring a leak-proof and long-lasting solution.

Efficient Filtration and Easy Maintenance

Strainers are engineered for efficient filtration of water, air, gas, steam, oil, or chemicals, featuring mesh screens, drain plugs for convenient cleaning, and self-cleaning (automatic) options. This facilitates reduced maintenance downtime and extends operational life, supporting uninterrupted flow in critical applications.

FAQs of Strainer Manufacturers in Mumbai:

Q: How do I select the appropriate mesh size and strainer type for my application?

A: The selection depends on the size and nature of particles you wish to filter, the required flow rate, and your application (such as water treatment, chemical, or oil & gas). Mesh sizes range from 10 to 500, and options include Y-type, basket-type, duplex, and T-type strainers. Our technical team can assist in determining the best configuration for your specific needs.Q: What is the process for ordering a customized strainer from Mumbai-based manufacturers?

A: You can provide details such as end connection standard (ANSI, DIN, BS), mesh size, required flow rate, pressure rating, body material, and any special coating or sealing needs. Our experts will guide you through the specification, design, and manufacturing process, ensuring the strainer meets your operational requirements.Q: Where can these strainers be used, and what media are they suitable for?

A: Our strainers are utilized across industrial, commercial, water treatment, chemical processing, oil & gas, and pharmaceutical applications. They are suitable for filtering various media, including water, air, gas, steam, oil, and chemicals, making them versatile components in several sectors.Q: When is it necessary to perform maintenance or clean the strainer?

A: Maintenance frequency depends on the nature of the media and the presence of solids in the flow. Drain plugs are provided for straightforward cleaning, and some models offer self-cleaning options. Regular inspection and cleaning enhance filtration efficiency and extend the units service life.Q: What are the benefits of using epoxy or hot-dip galvanized coatings on strainers?

A: Epoxy coatings and hot-dip galvanization provide excellent corrosion resistance, protect the strainer body from harsh environmental conditions, and significantly extend the service life, especially when handling aggressive media or being used in demanding applications.Q: How is the body of the strainer tested before delivery?

A: Each strainer undergoes hydrostatic testing at 1.5 times its design pressure to verify structural integrity and ensure a leak-proof operation before dispatch, aligning with rigorous industrial quality standards.Q: What options for sealing and connection types are available?

A: Seal types include EPDM, PTFE, NBR, graphite, and metal-to-metal, chosen based on the media and operating temperature. Connection methods offered are flanged, screwed (BSP/NPT), socket weld, and butt weld, accommodating various piping systems and standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in strainer Category

Conical Type Strainer Manufacturer in India

Price 4000 INR / Unit

Minimum Order Quantity : 1 Number

Media : Other, Liquids and gases

Material : Carbon Steel, Stainless Steel (SS304, SS316), Alloy Steel, Brass (as required)

Application : Pipeline filtration in oil, gas, chemical, and water treatment industries

Duplex Strainer Manufacturer in Surat

Price 4000 INR / Unit

Minimum Order Quantity : 1 Number

Material : MS

Size : Standard Sizes

Basket Strainer Manufacturer in Gandhidham

Price 2000 INR / Unit

Minimum Order Quantity : 1 Number

Media : Other

Material : Cast Iron

Size : 1/2 inch to 24 inch

Pot Type Strainer Manufacturer in Jamnagar

Price 800 INR / Unit

Minimum Order Quantity : 1 Number

Media : Water

Application : industrial

Size : All size

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free