Strainer Manufacturer in Kheda

Price 600 INR/ Unit

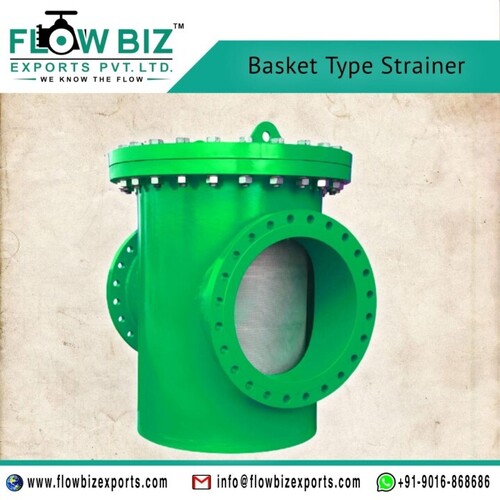

Strainer Manufacturer in Kheda Specification

- Valve Type

- Strainer Valve

- Material

- Stainless Steel, Carbon Steel, Cast Iron, Bronze

- Control System

- Manual, Optional Automation

- Valve Size

- DN15 to DN600

- Features

- Corrosion Resistant, Easy Cleaning, High Filtration Efficiency, Durable Construction

- Connection Type

- Flanged, Threaded, Socket Weld

- Application

- Industrial Filtration, Water Treatment, Chemical Processing, Oil & Gas, HVAC Systems

- Sealing

- Gasket and O-Ring Sealing

- Structure

- Y-Type, T-Type, Basket Type

- Type

- Pipeline Strainer

- Power

- Manual, Non-Electric

- Pressure

- Up to 40 bar

- Media

- Water, Oil, Steam, Chemicals

- Port Size

- inch to 24 inch

- Temperature

- -10C to 220C

- Disc

- Perforated or Mesh Screen

- Cleaning Method

- Drain valve/blow-off connection or easy basket removal for cleaning.

- Installation Orientation

- Horizontal and vertical inline options as per piping layout.

- Customization

- Design customization for special process or hazardous environments.

- Testing Pressure

- Hydrostatic testing at 1.5x rated pressure before shipment.

- Coating/Finish

- Epoxy powder coating, anti-corrosive paint for cast iron/cs models.

- Compliance

- Conforms to API, ASTM, IS standards for construction/fabrication.

- End Connection Standard

- ANSI, DIN, BS, IS flange standards as per requirement.

- Flow Rate Range

- From 5 m³/hr up to 5000 m³/hr depending on size and model.

- Screen Mesh Sizes

- 20 microns to 6mm, customized per fluid and application.

About Strainer Manufacturer in Kheda

About Strainer - FlowBiz Exports

A strainer is necessary for the piping system to filter dirt. Sometimes, the fluid carries some dust in the process, which must be strained to avoid any future damage. We design it in a way that protects against the damage that can cause to the entire system. If not filtered, a strainer can damage the pump, so it works effectively against stopping the dust or any other particle from entering the pump to work the whole piping system efficiently. It can lead to the development of harmful situations if not appropriately strained.

Versatile End Connection Standards

We manufacture strainers compatible with ANSI, DIN, BS, and IS flange standards, ensuring seamless integration into varying piping infrastructures. Connection options include flanged, threaded, or socket weld types, facilitating flexibility for different installation requirements across sectors.

Tailored Filtration and Performance

Our screen mesh sizes range from 20 microns up to 6mm and are customizable per fluid and application, providing high filtration efficiency for water, oil, steam, and chemicals. All units are hydrostatically tested at 1.5 times the rated pressure, and robust materials such as stainless steel, carbon steel, cast iron, or bronze are available.

Easy Maintenance & Cleaning Solutions

Designed for user-friendly servicing, our strainers feature drain valve/blow-off connections or removable baskets to enable swift and hassle-free cleaning. This minimizes downtime and supports long-term operational reliability in demanding environments.

FAQs of Strainer Manufacturer in Kheda:

Q: How do I select the suitable strainer type and end connection standard for my application?

A: To ensure compatibility with your piping system, choose from ANSI, DIN, BS, or IS flange standards. Selection depends on the process requirements, pressure ratings, and the nature of the fluid to be filtered. Our experts will guide you in choosing the optimal Y-Type, T-Type, or Basket Type strainer and connection type (flanged, threaded, or socket weld) based on your application.Q: What is the process for cleaning and maintaining these strainers?

A: Our strainers are designed for convenient maintenance. You can clean them using the integrated drain valve or blow-off connection for routine flushing. For more thorough cleaning, easily remove the basket or mesh screen, depending on the model. This helps maintain high filtration efficiency and extends the equipments lifespan.Q: When should I consider custom mesh sizes or materials for a strainer?

A: Custom mesh sizes and materials are recommended when your application involves unique fluids or demands specific filtration grades. If your process fluid is particularly aggressive or requires ultra-fine filtration (down to 20 microns), we tailor the screen mesh and materialstainless steel, carbon steel, cast iron, or bronzeas per your operational environment.Q: Where can these strainers be installed within a facility?

A: Our strainers can be installed on pipelines in horizontal or vertical orientation, adapting to your existing piping layout. They are suitable for locations requiring industrial filtration, water treatment, chemical processing, oil & gas, or HVAC systems, ensuring optimal placement for maximum process protection.Q: What are the primary benefits of using your strainers in industrial systems?

A: Our strainers provide robust protection for downstream equipment by effectively removing solids, thus reducing maintenance needs and process downtime. Corrosion-resistant coatings and durable construction ensure a long service life, while high filtration efficiency maintains optimal system operation and product quality.Q: Are these strainers compliant with industry standards and what testing do they undergo?

A: Yes, our strainers are manufactured in conformity with internationally recognized standards such as API, ASTM, and IS. Each unit undergoes hydrostatic testing at 1.5 times its rated pressure to guarantee reliability and safety before shipment.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in strainer Category

T Type Strainer Manufacturer in Gandhinagar

Price 1200 INR / Unit

Minimum Order Quantity : 1 Number

Features : Corrosion Resistant, Easy Maintenance, High Filtration Efficiency, Robust Construction

Material : Carbon Steel / Stainless Steel (SS304, SS316)

Media : Other, Water, Oil, Chemicals, Gas

T Type Strainer Manufacturer in Vadodara

Price 1700 INR / Unit

Minimum Order Quantity : 1 Number

Features : Corrosion resistant, easy maintenance, robust design, high dirt holding capacity

Material : Carbon Steel, Stainless Steel 304/316, Alloy Steel

Media : Other, Liquids, Gases, Steam, Chemicals

Basket Strainer Manufacturer in Gandhidham

Price 2000 INR / Unit

Minimum Order Quantity : 1 Number

Features : Best Quality

Material : Cast Iron

Media : Other

Color : Green

Pot Type Strainer Manufacturer in Mumbai

Price 2500 INR / Unit

Minimum Order Quantity : 1 Number

Features : Good Quality

Material : MS

Color : Blue

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free