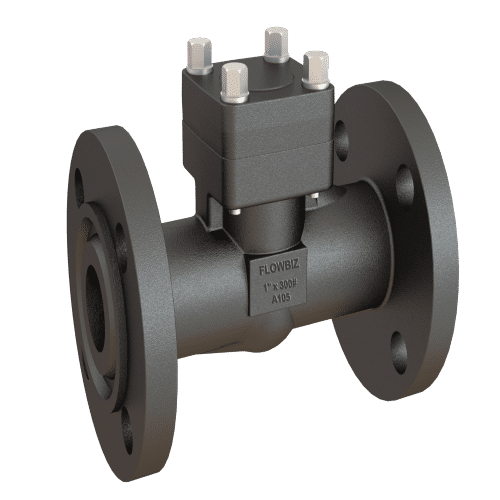

Pressure Sealed Check Valves

Price 6000 INR/ Unit

Pressure Sealed Check Valves Specification

- Material

- Carbon Steel, Alloy Steel, Stainless Steel

- Valve Size

- 2 to 24 (DN50 - DN600)

- Control System

- Manual or Actuation Available

- Features

- Pressure seal bonnet, non-return function, corrosion-resistant, suitable for high pressure and temperature applications

- Connection Type

- Flanged or Butt Weld End

- Valve Type

- Pressure Sealed Check Valve

- Structure

- Pressure Sealed Bonnet

- Sealing

- Metal to Metal or Soft Seated

- Application

- High-pressure piping systems, power plants, refineries, steam, and petrochemical industries

- Type

- Swing Check Valve

- Power

- Manual

- Pressure

- Class 150 to Class 2500

- Media

- Steam, Gas, Oil, Water

- Port Size

- DN50 - DN600

- Temperature

- -29C to 425C

- Disc

- Forged or Cast Steel

- Pin

- Stainless Steel

- Face to Face Dimension

- ASME B16.10 Standard

- Pressure Seal Gasket

- Stainless Steel with Graphite or other alloy suitable for high temperature

- Test Standard

- API 598, BS 6755

- Flow Direction

- Uni-directional

- End Connection Standard

- ASME B16.5, ASME B16.25

- Design Standard

- BS 1868, ASME B16.34

- Body Coating

- Anti-corrosive coating

- Surface Finish

- Shot Blasted & Painted

- Seat Ring Material

- Stellite Overlay or Equivalent

- Handwheel Material

- Cast Iron or Carbon Steel (where applicable)

About Pressure Sealed Check Valves

FlowBiz Exports Pvt Ltd Valves is a High Quality Tilting Disc Check Valves Manufacturer in Mumbai, Maharashtra, India. We are a leading manufacturer of Tilting Disc Check Valves in Mumbai and nearby areas.

Pressure Sealed Check Valves are intended for high pressure, high temperature applications in all types of fluid except where severe coking is a factor. The design and material selections provide excellent service in steam-generation stations, industrial chemical plants and thermal power plants.

Applications:

Check valves are used to prevent backflow and maintain pressure. They are commonly used as: a backup in case a pump fails, to help compressors and reciprocating pumps function, and when the system pressure exceeds the primary equipment capabilities. Check valves can be seen in industries such as refining, petrochemical, chemical, etc., oilfield production, water, steam, refining petro, and viscous fluids. Check valves are also commonly found in waste-water management systems and in manufacturing.

Product Details:

Brand: FlowBiz

Size - 2" to 36" (150#)

Type - Pressure seal

Manufacturing Standard - BS 1868 / API 6D

Body Materials - Carbon Steel, Alloy Steel, Stainless Steel, Duplex Steel

End connection - Flange End, Butt Weld

Precision Engineering for Demanding Applications

Our pressure sealed check valves are meticulously built to comply with stringent standards such as ASME B16.10, API 598, and BS 1868. The valves are manufactured from premium carbon steel, alloy steel, or stainless steel and finished with an anti-corrosive coating to withstand extreme industrial environments. They're expertly designed for high-pressure pipelines, refineries, and steam systems.

Advanced Sealing and Flow Assurance

Fitted with stainless steel gaskets reinforced with graphite or highly heat-resistant alloys, these swing check valves offer exceptional sealing integrity. The unit's metal-to-metal or soft-seated options assure tight shutoff and reliable non-return service in high-temperature conditions, making them a preferred choice for critical flow control in power generation and oil & gas sectors.

Versatile Design and Easy Integration

With face-to-face and end connection dimensions conforming to leading ASME and BS norms, integration into new or existing setups becomes straightforward. Shot blasted, painted exteriors, and flexible connection types-which include both flanged and butt weld ends-provide adaptability across a spectrum of pipeline configurations, all while safeguarding long-term valve performance.

FAQ's of Pressure Sealed Check Valves:

Q: How does a pressure sealed check valve ensure unidirectional flow in high-pressure systems?

A: The pressure sealed check valve is designed as a swing type, allowing fluid to pass in one direction only. When the flow reverses, the disc swings shut automatically, preventing backflow and ensuring the non-return function. This is particularly critical in high-pressure and high-temperature pipelines for safety and equipment protection.Q: What standards do these check valves adhere to for testing and construction?

A: Our pressure sealed check valves comply with rigorous construction standards such as ASME B16.34 and BS 1868. For face-to-face dimensions, they follow ASME B16.10, while testing is done according to API 598 and BS 6755 to assure reliable performance and safety under various operational conditions.Q: When should I choose a pressure sealed check valve over other valve types?

A: Pressure sealed check valves are ideally suited for services involving high pressure and high temperature, such as in power plants, refineries, and steam lines. Their design offers superior sealing and safety advantages in such demanding environments compared to conventional check valves.Q: Where can these valves be installed, and what are the connection options?

A: These check valves are suitable for installation in steam, oil, gas, and water pipelines in industries like petrochemicals and power generation. They are available with flanged or butt weld end connections, conforming to ASME B16.5 and ASME B16.25 standards for versatile system integration.Q: What is the process for maintaining a pressure sealed check valve?

A: Regular inspections for leakage, seat wear, or disc integrity should be performed. The robust design, including stellite overlay seat rings and corrosion-resistant coatings, minimizes maintenance needs. When necessary, servicing can be done without removing the valve from the line, especially for metal-seated models.Q: How does the anti-corrosive coating benefit valve longevity?

A: The anti-corrosive coating protects the valve's body from harsh operating environments, such as corrosive media or extreme weather, significantly extending the valve's service life and maintaining optimal performance in industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Check Valve Category

Leader Make Gun Metal Horizontal Check Valve Flanged End

Price 800 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Gun Metal Flanged End Check Valve

Port Size : Varies; refer to size options from 15mm to 200mm

Media : Gas

Temperature : Suitable up to 80C

2/2 Way Miniature Low Flow Proportional Valve

Price 3200 INR / Number

Minimum Order Quantity : 1 Unit

Type : 2/2 Way Miniature Low Flow Proportional Valve

Port Size : M5 / 1/8 NPT (custom options available)

Media : Water

Temperature : 0C to 50C

Lift Check Valve Manufacturer in Rajkot

Price 500 INR / Unit

Minimum Order Quantity : 1 Number

Type : Flanged End, Screwed End

Port Size : DN15 to DN200

Media : Other, Water, Oil, Steam, Air, Gas

Temperature : Up to 220C

Lift Check Valve Manufacturer in Surat

Price 2000 INR / Unit

Minimum Order Quantity : 1 Number

Type : Check Valve

Port Size : DN50

Media : Other, Liquid or Gas

Temperature : High temperature compatibility

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free