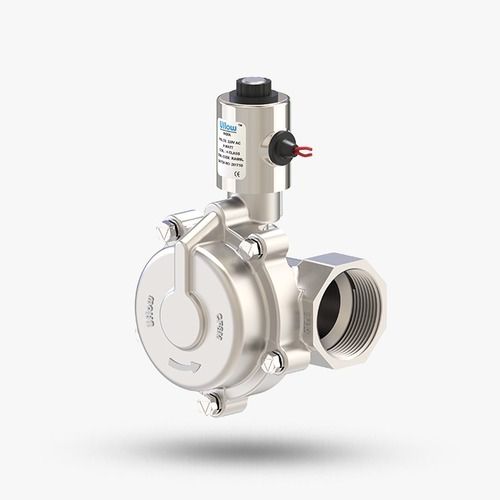

Pilot Operated Piston Type Steam Valve (NC/NO)

Price 7600 INR/ Number

Pilot Operated Piston Type Steam Valve (NC/NO) Specification

- Features

- High reliability, Minimum maintenance, Energy efficient, Fast switching

- Valve Type

- Steam Solenoid Valve, Pilot Operated

- Valve Size

- DN15 to DN50

- Connection Type

- Screwed / Flanged End

- Control System

- Pilot Operated Piston Actuation

- Material

- Forged Brass / Stainless Steel / SS304 / SS316

- Sealing

- PTFE / NBR / Viton gasket

- Structure

- Pilot Operated Piston Type

- Voltage

- 220V AC / 24V DC / 110V AC / 415V AC

- Application

- Steam control, Boiler systems, Process industries, Automatic steam distribution

- Type

- Normally Closed (NC) / Normally Open (NO)

- Power

- Pneumatic / Solenoid actuated

- Pressure

- 0.5 to 10 bar (Max 16 bar available)

- Media

- Steam, Air, Hot Water, Non-corrosive liquids and gases

- Port Size

- 1/2 inch to 2 inches

- Temperature

- -10C to 180C

- Disc

- Stainless Steel / Brass

- Pin

- 2 Pin / 3 Pin (as per actuator requirement)

- End Connection Standard

- BSP / NPT / Flanged to ASME/ANSI/DIN

- Ambient Temperature

- up to 70°C

- Accessories

- Manual override, Indicator light, Cable gland, Additional coil voltage on request

- Weight

- Varies per size: approx. 1.2 kg (DN15) to 4.3 kg (DN50)

- Cycle Life

- Over 1,000,000 cycles

- Insulation Class

- Class F or H

- Mounting Position

- Any (Horizontal preferred, coil upwards)

- Coil Enclosure

- IP65 Weatherproof

- Flow Direction

- Unidirectional (marked with arrow on valve body)

- Body Finish

- Nickel Plated (for brass); Natural Finish (for stainless steel)

- Leakage Class

- Class VI (Bubble Tight)

- Response Time

- < 1 second

- Serviceability

- Field serviceable, Easy spares availability

About Pilot Operated Piston Type Steam Valve (NC/NO)

Port : Refer below technical data sheet (Available BSP / NPT)

End Connection : Screwed / Flange

Body Material : SS ASTM A351 Grade CF8 / CF8M

Circumstance Temp : -10C to 70C

Media : Steam, Hot Water, Hot Fluid, Oil

Main Features : Internal Parts are in superior corrosion resistance steel,

(Equivalent to SS316L) Suitable for Food Industries, Pharmaceuticals,

Chemical application & Highly corrosive environment.

Coil Features : High Reliability Unaffected by Voltage Surges.

Easy coil changes coil lockable in 4X90 position or freely movable in

between as require.

Coil Housing : Epoxy square coil, Metallic round enclosure,

IP-67 Flameproof enclosure, IP-68 Weatherproof enclosure.

Optional Feature : 90% Power saver series also available, Water hammering reducer

also available to avoid water hammer forces.

Other Specification Data : Available on Request.-Manual Override

Versatile Mounting and Flow Control

This steam valve can be installed in any orientation, with horizontal mounting and coil upwards being preferred for optimal performance. The unidirectional flow, indicated by a marked arrow on the valve body, ensures correct installation and reliable operation in demanding systems.

Robust Construction for Industrial Demands

Available in forged brass or stainless steel, with finishes suited to each material, and seals made from high-quality PTFE, NBR, or Viton. Valve sizes range from DN15 to DN50, making it suitable for a variety of industrial applications. Cycle life exceeds one million operations, supporting long-term serviceability.

Efficient and Reliable Actuation

Pilot Operated Piston Actuation ensures precise and rapid valve operation with response times below one second. The design incorporates energy efficiency, field serviceability, and easy access to spare parts. Accessories like manual override, indicator lights, and cable glands enhance user control and maintenance.

FAQ's of Pilot Operated Piston Type Steam Valve (NC/NO):

Q: How should I install the Pilot Operated Piston Type Steam Valve for optimal performance?

A: Install the valve in any mounting position, although a horizontal orientation with the coil facing upwards is recommended to achieve the best operational efficiency and longevity.Q: What types of media can be controlled by this steam solenoid valve?

A: This valve is designed to handle steam, air, hot water, and various non-corrosive liquids and gases, making it ideal for process industries and boiler systems.Q: When should I select the Normally Closed (NC) versus the Normally Open (NO) type?

A: Select a Normally Closed valve if you need to stop flow when idle, and choose Normally Open when flow should continue during idle periods. Selection depends on your system's safety and process needs.Q: Where can this valve be used in industrial applications?

A: It is suitable for steam control, automatic steam distribution, and process industries, including boiler systems and power generation setups, due to its robust construction and versatile design.Q: What is the process for servicing or replacing parts in this valve?

A: The valve is field serviceable, allowing easy access for replacement of spares and maintenance without requiring complete removal. Spare parts are easily available through the manufacturer or supplier.Q: How does the valve's cycle life and leakage class benefit my operations?

A: With a cycle life exceeding 1,000,000 operations and Class VI (Bubble Tight) leakage rating, the valve offers exceptional durability and zero leakage for reliable long-term service.Q: What accessories and voltage options are offered with this valve?

A: Accessories include manual override, indicator light, and cable gland. Coil voltage options are available upon request, including 220V AC, 24V DC, 110V AC, and 415V AC to suit diverse applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Piston Valve Category

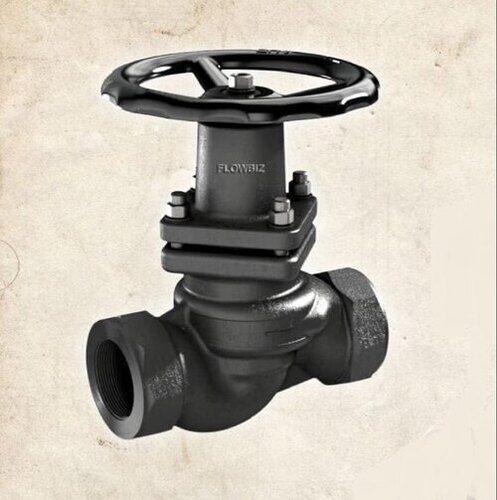

Piston Valves Manufacturer in Pune

Price 900 INR / Unit

Minimum Order Quantity : 1 Number

Media : Other, Steam, Air, Water, Oil, Gas

Structure : Other, Piston Type

Port Size : 15 mm to 200 mm

Application : Industrial, Water, Oil & Gas, Chemical Processing

Piston Valve Manufacturer In Mandvi

Price 4000 INR / Unit

Minimum Order Quantity : 1 Number

Media : Other, Steam, Water, Gas, Oil

Structure : Other, Piston

Port Size : Customized as per requirement

Application : Industrial Fluid Control

Piston Valve Manufacturer in Rajkot

Price 500 INR / Unit

Minimum Order Quantity : 1 Number

Media : Other, Steam, Oil, Gas, Water

Structure : Other, Piston Type

Port Size : 1/2 to 8 (DN15 to DN200)

Application : Industrial Fluid Control

FORBES Marshall Piston Valve Flanged End

Price 6000 INR / Unit

Minimum Order Quantity : 1 Unit

Media : Gas

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free