Pharma Butterfly Valve Manufacturer in India

Price 1500 INR/ Number

Pharma Butterfly Valve Manufacturer in India Specification

- Connection

- Tri-clamp / Flange / Welded Ends

- Valve Type

- Butterfly Valve

- Material

- Stainless Steel 316/316L

- Power Source

- Manual / Pneumatic / Electric

- Pressure

- Up to 10 Bar

- Media

- Pharma Liquids, Water, Steam, Chemicals

- Working Temperature

- -20C to +180C

- Port Size

- 1 to 8 (Inches)

- Shape

- Round / Disc Type

- End Connection Standard

- DIN, SMS, IDF, ISO

- Operation

- Lever Operated / Actuated

- Application

- Pharmaceutical, Food & Beverage, Cosmetic, Biotech Industry

- Seal Material

- EPDM / Silicone / PTFE / Viton

- Surface Finish

- Mirror Polished (Ra < 0.6m)

- Size Range

- DN25 to DN200

- Leakage Class

- Class VI (Bubble Tight)

- Design Standard

- ASME BPE / DIN / ISO

- Body Construction

- One-Piece / Two-Piece

- Testing

- 100% Factory Tested

Pharma Butterfly Valve Manufacturer in India Trade Information

- Minimum Order Quantity

- 1 Unit

- Delivery Time

- 7 Days

About Pharma Butterfly Valve Manufacturer in India

offers Butterfly valves for pharmaceutical, cosmetic, biotech, food, and suitable chemical industries applications. FlowBiz One-piece crevice-free disc polished to mirror finish to maximize flow and easy maintenance. The compact design gives weight and space utilization.

Size Range:2 inches to 16 inches (50mm to 400mm)

Pressure / Temperature Rating: Working Pressure: MAX. 3 to 4 Kg /Cm2 Operating Temperature : -50 C to + 400 C

Precision Engineered for Hygiene-Critical Applications

Our butterfly valves are designed for industries where hygiene and contamination control are essential, such as pharmaceuticals and biotechnology. The mirror-polished surfaces and high-grade seal materials ensure sterile operation, while compliance with ASME BPE, DIN, and ISO standards makes them suitable for global markets. Each valve undergoes strict factory testing for performance and reliability, offering peace of mind for mission-critical processes.

Versatile Operation and Connection Options

Choose between manual (lever), pneumatic, or electric actuation to fit your process requirements. Flexible end connection standards, including tri-clamp, flange, and welded ends, allow for seamless integration into your existing system. With various body constructions, seal materials, and port sizes, our valves adapt easily to your specific application needs-from chemical handling to food ingredient processing.

FAQ's of Pharma Butterfly Valve Manufacturer in India:

Q: How do I select the appropriate seal material for my butterfly valve application?

A: The choice of seal material depends on the media being handled and process conditions. EPDM offers excellent resistance to water and steam, Silicone is ideal for sterilization processes, PTFE provides superior chemical resistance, and Viton suits aggressive chemicals. Consult your process specifications to determine the best option for durability and compatibility.Q: What is the benefit of a mirror-polished surface finish in these valves?

A: A mirror-polished surface (Ra <0.6m) significantly reduces the risk of product buildup and microbial contamination, making it ideal for sanitary industries such as pharmaceuticals, food & beverage, and cosmetics. This finish also ensures easier cleaning and maintenance, promoting long-term process reliability.Q: When should I choose an actuated butterfly valve over a manual (lever-operated) one?

A: Actuated butterfly valves-pneumatic or electric-are recommended when automation, remote control, or frequent cycling is required. Manual (lever) operation is suitable for simple on/off applications or where automation is not necessary. Selection depends on process complexity, desired operational efficiency, and safety considerations.Q: Where are your butterfly valves commonly used?

A: Our butterfly valves are widely utilized in pharmaceutical, food & beverage, cosmetic, and biotech industries across India and globally. Typical applications include handling pharma liquids, water, steam, and chemicals where sanitary, leak-tight performance is essential.Q: What standards do your butterfly valves comply with, and why is this important?

A: The valves conform to ASME BPE, DIN, and ISO standards, ensuring compatibility with international systems and strict hygiene requirements. Compliance guarantees consistent quality, regulatory acceptance, and seamless integration into standardized process lines.Q: What is your process for ensuring leak-tight performance in your valves?

A: Each butterfly valve undergoes rigorous 100% factory testing to verify bubble-tight (Class VI) leakage performance. This involves pressure testing up to 10 bar, ensuring they meet stringent reliability criteria required in sanitary and critical process environments.Q: What are the advantages of choosing a one-piece or two-piece body construction?

A: One-piece body construction offers superior integrity and easier cleaning, ideal for sanitary applications. Two-piece construction provides greater flexibility for maintenance and replacement of internal components, making it suitable for applications where easy servicing is required.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Butterfly Valve Category

Pharma Butterfly Valve Manufacturer in Jamnagar

Price 800 INR / Unit

Minimum Order Quantity : 1 Number

Size : All size

Material : Stainless Steel

Power Source : Manual

Connection : Other, TriClamp / Flanged

Spherical Disc Butterfly Valve Manufacturer in Vapi

Price 5100.00 INR / Unit

Minimum Order Quantity : 1 Number

Size : 1/2" to 12"

Material : Stainless Steel

Power Source : Manual

Connection : Other, Flanged

Double Flange Butterfly Valve Manufacturer in Ahmedabad

Price 2000.00 INR / Unit

Minimum Order Quantity : 1 Number

Size : 50MM

Material : Cast Iron

Power Source : Manual

Connection : Other, Flanged

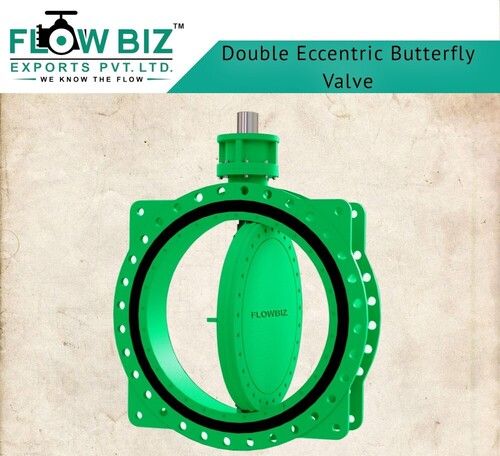

Double Eccentric Butterfly Valve Manufacturer in Vapi

Price 5800.00 INR / Unit

Minimum Order Quantity : 1 Number

Size : 1/2 inch

Material : Cast Iron

Power Source : Manual

Connection : Other, Flanged

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS