Parallel thread plug

Price 500 INR/ Number

Parallel thread plug Specification

- Size

- 1/8 to 2 (BSPP/BSPT Parallel Thread)

- Sealing

- PTFE (Teflon) Tape or O-ring

- Application

- Hydraulic and Pneumatic Systems, Pipe Fittings, Industrial Applications

- Connection

- Male Threaded

- Material

- Brass

- Valve Structure

- Plug

- Media

- Water, Oil, Gas

- Temperature of Media

- -10C to +120C

- Weight

- Approx. 50-120 g (depending on size)

- Dimension (L*W*H)

- Varies by size (see size specification)

- Power Mode

- Manual

- Customization

- Available for Size and Finish

- Corrosion Resistance

- High

- Surface Finish

- Nickel Plated, Natural Brass or Chrome Plated

- Thread Standard

- BSPP Parallel (ISO 228/1), Also available in BSPT

- Working Pressure

- Up to 16 Bar (232 psi)

- Leakage Test

- 100% Factory Tested

- Head Type

- Hex Head/Flat Head Option

About Parallel thread plug

Specifications

Fluid : Air

Max. operating pressure : 10 Bar

Ambient temperature : -10C to +60C

Threaded connection : Male : R - Taper thread, Female : G - Parallel thread

Media temperature : +5C to 50C

Applicable tube material : Nylon, Polyurethane

Applicable tube size (OD) : 4, 6, 8, 10, 12, 14, 16

Recommended tolerance for tube OD : 0.1 mm

Versatile Application Range

Suitable for hydraulic systems, pneumatic circuits, and various industrial pipe fittings, this parallel thread plug handles water, oil, and gas under demanding conditions. Its robust design ensures dependable performance across multiple sectors including manufacturing, infrastructure, and utilities.

Durable Construction and Finish

Constructed from high-quality brass, the plug comes in three surface finishes: nickel-plated, natural brass, or chrome-plated. These enhance corrosion resistance, increase durability, and ensure long-term reliability, even in harsh operating environments.

Guaranteed Leak-Free Performance

Every plug undergoes a 100% factory leakage test, assuring users of the product's premium sealing capabilities. For installation, use PTFE (Teflon) tape or O-ring sealing on the male threaded connections to prevent leaks and maintain system integrity.

FAQ's of Parallel thread plug:

Q: How do I install the BSPP Parallel Thread Plug in my piping system?

A: To install, simply screw the male threaded plug into the corresponding female BSPP/BSPT pipe fitting. For optimal sealing, apply PTFE (Teflon) tape or use an O-ring on the thread before tightening the plug using a wrench on its hex or flat head.Q: What are the benefits of the available surface finishes for this plug?

A: Nickel-plated, natural brass, and chrome-plated finishes increase corrosion resistance, enhance durability, and ensure the plug withstands harsh media such as water, oil, and gas. This extends the plug's lifecycle and maintains system safety over time.Q: Where can these plugs be used and for which media are they suitable?

A: These plugs are ideal for use in hydraulic and pneumatic systems, industrial pipework, and general gas, oil, and water applications. Their high corrosion resistance and pressure rating up to 16 bar make them suitable for demanding and varied environments.Q: What is the process for leak testing, and why is it important?

A: Each plug is subjected to a 100% factory leakage test to ensure reliable sealing and system safety. Leak testing detects any imperfections, ensuring the plugs deliver consistent performance and prevent costly downtime from leaks.Q: Can I request custom sizes or finishes for bulk orders?

A: Yes, customization options are available for both size and surface finish to meet specific project requirements. Please contact the manufacturer, exporter, supplier, or trader in India for detailed specifications and bulk order customization.Q: When should I select a hex head versus a flat head plug?

A: Choose a hex head for easier tightening and removal with a wrench, especially in applications where frequent maintenance occurs. Opt for a flat head when space is limited or where a more flush installation is required.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

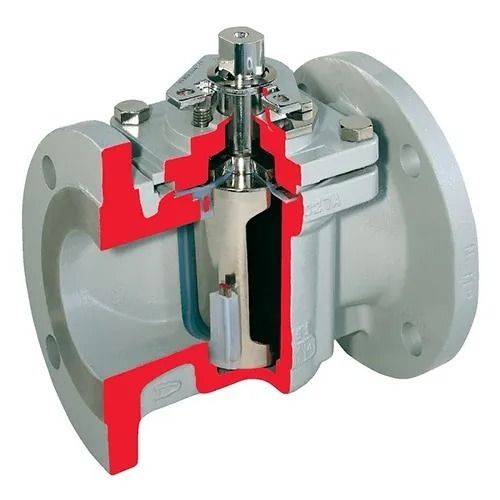

More Products in Plug Valve Category

Lubricated Plug Valves

Price 3000 INR / Unit

Minimum Order Quantity : 1 Number

Size : 1/2 to 24 (DN15 to DN600)

Material : Other , Carbon Steel, Stainless Steel, Cast Iron

Valve Structure : Other, ThreePiece Body or Lubricated Plug Design

Sleeved Plug Valve Manufacturer in Vadodara

Price 1300.00 INR / Unit

Minimum Order Quantity : 1 Number

Size : 1/2" to 16"

Material : Carbon Steel

Valve Structure : Plug Valve

Usage : Industrial

Sleeved Plug Valves Manufacturer in Gandhidham

Price 2200.00 INR / Unit

Minimum Order Quantity : 1 Number

Size : 1/2"16

Material : Carbon Steel

Valve Structure : Plug Valve

Usage : Industrial

Double Block and Bleed Plug Valves Manufacturer in Pune

Price 2000.00 INR / Unit

Minimum Order Quantity : 1 Number

Size : 2inch

Material : Stainless Steel

Valve Structure : Plug Valve

Usage : Industrial

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free