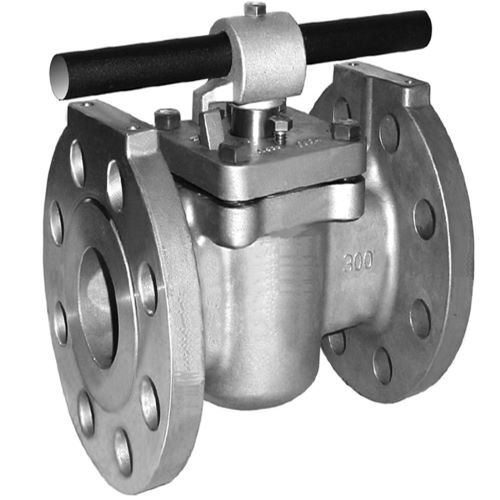

Lubricated Plug Valves

Price 3000 INR/ Unit

Lubricated Plug Valves Specification

- Sealing

- Grease/Lubricant Seated, Metal Seated

- Connection

- Flanged, Screwed, Butt Weld

- Application

- Petrochemical, Oil & Gas, Water Treatment, Chemical Industry

- Size

- 1/2 to 24 (DN15 to DN600)

- Material

- Carbon Steel, Stainless Steel, Cast Iron

- Valve Structure

- Three-Piece Body or Lubricated Plug Design

- Media

- Oil, Gas, Water, Acid

- Temperature of Media

- -20C to 425C

- Weight

- Varies by Size (Approx. 15 kg to 300 kg)

- Dimension (L*W*H)

- Customizable as per Size

- Power Mode

- Manual (Hand Lever, Gear Operated)

- End Standards

- ANSI, DIN, BS

- Fire Safe

- Available as per API 607

- Maintenance

- Online Maintenance Possible with Grease Injection

- Plug Material

- Matching Body Material or Special Alloys

- Face to Face Standard

- ASME B16.10

- Design Standard

- API 599, API 6D

- Testing Standard

- API 598, BS 6755

- Antistatic Device

- Provided on Request

- Leakage Class

- Class IV, V (Optional)

- Operation Type

- Quarter Turn

- Body Coating

- Epoxy Painted or Anti-Corrosive Coated

- Pressure Rating

- Class 150 to 600 (PN16 to PN100)

About Lubricated Plug Valves

FlowBiz Exports Pvt Ltd is a High Quality Lubricated plug valve Manufacturer in Mumbai, Maharashtra, India. We are a leading manufacturer of Lubricated plug valve in Mumbai and nearby areas.

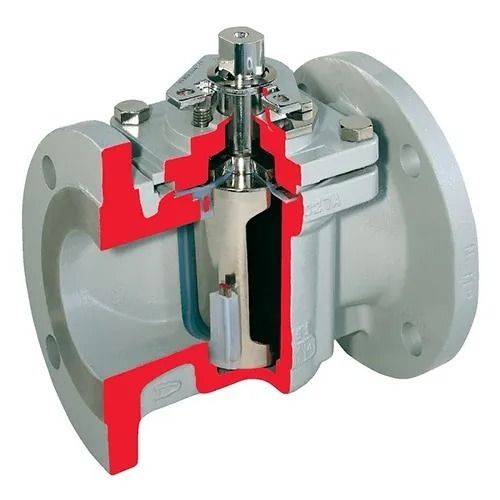

Lubricated plug valve consists of a cavity in the middle of plug along its axis. This cavity is closed at the bottom and fitted with a sealant-injection fitting at the top. The sealant is injected into the cavity, and a check valve below the injection fitting prevents the sealant from flowing in the reverse direction.

Advantages:

i Sealant helps create a renewable seal between plug and the body which prevents internal leakage.

i It also protects the seating surface against corrosion.

i It also acts as a lubricant and reduces force required to operate the valve.

i Lubricant pressure momentarily lifts the plug from the seat and makes it easy to turn.

i Also its high pressure assures no trapping of solids between valve body and plug.

product Details:

Usage/Application - Hot oil water industrial

Pressure - Low Pressure

Valve Size - 4

Brand - FlowBiz

Size - 4

Material - Cast iron

Versatility for Multiple Applications

Our lubricated plug valves cater to a wide array of industries including oil & gas, petrochemicals, water treatment, and chemical processing. Their compatibility with various media-such as oil, gas, water, and acids-and wide temperature tolerance (-20C to 425C) ensures reliable operation in complex environments.

Reliable Sealing and Minimal Leakage

Equipped with grease or metal seated sealing options, these plug valves deliver dependable shutoff performance with leakage classes up to Class V. The design adheres to international standards such as API 599, 6D, and API 598 for testing, ensuring safety, reduced emissions, and trusted reliability even in critical applications.

Customizable Design Features

Customers can choose from different end connections (flanged, screwed, butt weld), body coatings (epoxy painted or anti-corrosive), and plug materials (matching body or specialty alloys) to suit specific operational needs. The three-piece or lubricated plug design and availability of manual, hand lever, or geared operation add further flexibility.

FAQ's of Lubricated Plug Valves:

Q: How does the lubricated plug valve enable online maintenance?

A: These valves are designed with a feature that allows grease injection while the system is still operational, making it possible to perform online maintenance. This minimizes process interruptions and ensures continuous reliability, especially important in critical applications.Q: What sealing options are available and how do they benefit various applications?

A: The valves offer grease/lubricant seated or metal seated sealing options. Grease seating provides enhanced sealing for frequent operation, while metal seating ensures durability under high temperatures or abrasive media. Both options help reduce leakage, meeting Class IV or V leakage requirements.Q: Where can lubricated plug valves be applied most effectively?

A: These valves are most effective in sectors such as petrochemicals, oil & gas, water treatment, and the chemical industry. Their corrosion-resistant build and pressure handling make them ideal for handling a range of fluids under challenging environmental conditions.Q: What end connection standards can be specified for these valves?

A: Customers can select from ANSI, DIN, or BS standard end connections. The valves support various connection types including flanged, screwed, and butt weld, ensuring compatibility with global piping systems and project requirements.Q: When should special alloy plug materials be considered over matching body material?

A: Special alloy plugs are recommended for applications involving aggressive chemicals, high temperatures, or fluids that could cause standard materials to degrade. These alloys enhance resistance to corrosion and wear, prolonging the valve's service life.Q: How does the antistatic device improve valve safety?

A: The antistatic device, provided upon request, prevents static charge buildup between the plug and the valve body. This is particularly important when controlling flammable media, as it significantly lowers the risk of spark-induced accidents.Q: What benefits do epoxy and anti-corrosive coatings offer for valve longevity?

A: Epoxy and anti-corrosive coatings shield the valve's body from environmental factors, chemical exposure, and moisture. This effectively increases the valve's lifespan, reduces maintenance needs, and maintains performance in harsh service conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plug Valve Category

PTFE Sleeved Plug Valves

Price 6000 INR / Unit

Minimum Order Quantity : 1 Number

Material : Other , Body: Cast Iron/Carbon Steel/Stainless Steel; Sleeve: PTFE (Polytetrafluoroethylene)

Size : DN15 to DN200 (1/2 to 8)

Power Mode : Other, Manual (Lever or Gear operated)

Valve Structure : Other, 2way plug valve with PTFE sleeve lining

Plug Valve Manufacturer in India - FlowBiz

Price 2500 INR / Unit

Minimum Order Quantity : 1 Number

Material : Other , Cast Iron, Ductile Iron, Stainless Steel, Carbon Steel

Size : 15mm to 400mm

Power Mode : Other, Manual, Pneumatic, Electric

Valve Structure : Other, Eccentric / Lubricated / NonLubricated

Plug Valve Manufacturer in Mandvi

Price 4000.00 INR / Unit

Minimum Order Quantity : 1 Number

Material : Cast Iron

Size : 1/2" to 12"

Power Mode : Manual

Valve Structure : Plug Valve

Sleeved Plug Valve Manufacturer in Vadodara

Price 1300.00 INR / Unit

Minimum Order Quantity : 1 Number

Material : Carbon Steel

Size : 1/2" to 16"

Power Mode : Manual

Valve Structure : Plug Valve

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free