Inline Check Valve Manufacturer in Pune

Price 2000 INR/ Unit

Inline Check Valve Manufacturer in Pune Specification

- Valve Size

- Varies (1/2 to 4)

- Connection Type

- Threaded/Female BSP/NPT

- Control System

- Manual operation

- Material

- Stainless Steel, Brass, Cast Iron

- Features

- Compact design, Corrosion resistant, Low cracking pressure

- Valve Type

- Non-return, Spring-loaded

- Structure

- Inline type, Simple single disc

- Application

- Flow Control, Preventing backflow, Water and Air Systems

- Sealing

- EPDM/NBR/PTFE as per requirement

- Type

- Inline Check Valve

- Power

- Manual (No external power required)

- Pressure

- Up to 16 bar

- Media

- Water, Air, Oil, Gas

- Port Size

- 1/2 to 4

- Temperature

- -10C to 80C

- Disc

- S.S. 304/316 Disc

- Pin

- Stainless Steel Pin

- End Connection

- Screwed, Flanged as per IS/ANSI standards

- Body Finish

- Polished/Coated for enhanced durability

- Cracking Pressure

- Low (typically <0.5 bar)

- Standards

- Conforms to ASTM/BS/IS specifications

- Testing

- 100% Hydrostatic & Pneumatic tested

- Mounting Position

- Horizontal/Vertical

- Flow Direction

- Unidirectional

- Spring Material

- Stainless steel, corrosion resistant

- Service Life

- Long-life, maintenance-free

About Inline Check Valve Manufacturer in Pune

Product Overview

Key Features:

We are established to provide superb quality Inline Check Valves. This valve is acquired from reliable sources in the industry under the guidance of skilled procuring agents. The product we offer has different technical features and specifications.

Product Specification:

Valve Size: up to 4 inch

Size: 15NB TO 125NB

Material: Steel

Connection: Large flanges with connection dimensions by standards: DIN, ANSI, SOC.SA an

Minimum Order Quantity: 1 Piece

Precision Engineering for Flow Control

Our inline check valves are built to ensure unidirectional flow in demanding water, air, oil, and gas systems. The compact inline design, low cracking pressure (<0.5 bar), and diverse sealing options provide reliable performance in both industrial and commercial environments. Every valve passes rigorous hydrostatic and pneumatic testing, guaranteeing operational safety and reliability.

Durable and Versatile Construction

Manufactured from high-quality stainless steel, brass, or cast iron, each check valve features a polished or coated finish for improved longevity and corrosion resistance. Available with screwed, threaded, or flanged connections (BSP/NPT), they accommodate diverse installation needs. The simple single disc structure and stainless steel spring ensure maintenance-free operation throughout the valve's lifecycle.

Conformance with Global Standards

Our check valves are meticulously engineered to meet ASTM, BS, and IS standards. Every product is subject to stringent quality controls during production, and is suitable for export, supply, and trading on the international stage. The rigorous testing and standards compliance ensure consistent performance even in challenging conditions.

FAQ's of Inline Check Valve Manufacturer in Pune:

Q: How does the inline check valve prevent backflow in piping systems?

A: The inline check valve uses a spring-loaded single disc mechanism that allows fluid to flow in one direction and automatically closes to prevent reverse flow, thereby safeguarding the system against contamination or damage from backflow.Q: What connection options are available for these check valves?

A: This product is available with screwed, flanged, or threaded end connections as per IS/ANSI standards, including female BSP or NPT ports, ensuring compatibility with various piping configurations.Q: Where can these inline check valves be installed?

A: They can be mounted in both horizontal and vertical positions, making them suitable for diverse installation environments in water, air, oil, and gas applications.Q: What materials are used in the construction of these valves?

A: The valves are manufactured from stainless steel, brass, or cast iron, with components such as springs and pins made of corrosion-resistant stainless steel. Sealing options include EPDM, NBR, or PTFE, depending on the operational requirement.Q: How is product quality ensured during manufacturing?

A: Every valve undergoes 100% hydrostatic and pneumatic testing and is manufactured to conform with ASTM, BS, and IS standards, ensuring leak-free and safe operation under rated pressures up to 16 bar.Q: What is the typical service life and maintenance requirement for these check valves?

A: Thanks to robust materials, coatings, and a simple internal structure, these check valves offer a long service life and are virtually maintenance-free under standard operating conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Check Valve Category

Inline Check Valve Manufacturer Gandhidham

Price 2000 INR / Unit

Minimum Order Quantity : 1 Number

Type : Inline check valve

Media : Other, Liquid, Gas

Application : Suitable for water, oil, gas and process industries

Gun Metal Vertical Lift Check Valve

Price 400 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Gun Metal Vertical Lift Check Valve

Media : Gas

Application : Industrial

Size : Different Available

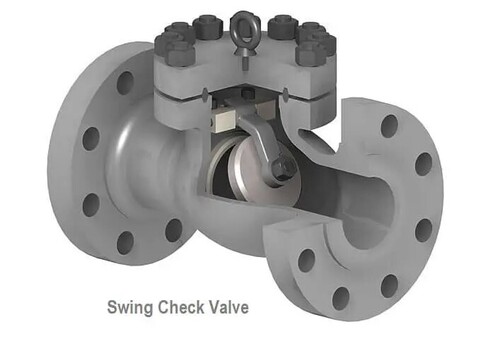

Swing Check Valve in India

Price 4000 INR / Unit

Minimum Order Quantity : 1 Number

Size : Standard Sizes

Non Slam Check Valve Manufacturer in Ahmedabad

Price 2000 INR / Unit

Minimum Order Quantity : 1 Unit

Size : Standard Sizes

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS