Double Flange Butterfly Valve Manufacturer in Gandhinagar

Price 600 INR/ Unit

Double Flange Butterfly Valve Manufacturer in Gandhinagar Specification

- Structure

- Double Flange

- Connection

- Flanged

- Caliber

- Full Bore

- Pressure

- PN10/PN16/PN25

- Channels

- Single Channel

- Material

- Cast Iron, Ductile Iron, Stainless Steel, Carbon Steel

- Power

- Manual, Electric, Pneumatic

- Media

- Water, Oil, Gas, Chemicals

- Temperature of Media

- -10C to 120C

- Port Size

- 50mm to 1200mm

- Flange

- PN10, PN16, PN25

- Finish

- Epoxy Coated, Painted

- Application

- Water Treatment, Plumbing, HVAC, Industrial Pipeline

- Mounting

- ISO 5211 Top Flange for Actuator Mounting

- Seat Material

- EPDM, Nitrile Rubber, PTFE

- Test Pressure

- Body: 1.5 x Rated, Seat: 1.1 x Rated

- Operating Torque

- Low friction for ease of operation

- Sizes Available

- 2" to 48"

- Disc Material

- Cast Iron/SS304/SS316/Ductile Iron/Aluminum Bronze

- End Connection

- Double Flanged (As per ISO 2531/IS 1538)

- Face to Face Dimensions

- As per IS 5163 / EN 558

- Leakage Rate

- Zero leakage/Class VI

- Operation Type

- Gear Operated, Lever Operated, Motorized

- Body Coating

- Fusion Bonded Epoxy (Standard 300 Microns)

About Double Flange Butterfly Valve Manufacturer in Gandhinagar

Introduction:

FlowBiz Export Private Limited is a renowned manufacturer and supplier of Double Flange Butterfly Valve in Gandhinagar, India. FlowBiz has established itself as a trusted name in the valve manufacturing industry with a strong focus on quality, innovation, and customer satisfaction.

Suitable for a variety of applications offering durability, reliability and cost effective alternative to ball valves.

Available with a Pneumatic or Electric Actuator and range of additional

Fully assembled and tested

Size & Connections

40mm (1 1/2) to 1200mm (48ï)

Double Flanged

Duty

Water

Steam

Gas

Oil

Acids

Solvents

Fuel

We are a Manufacturer, Supplier, and Exporter of Double Flange Butterfly Valve in Gandhinagar, Ahmedabad, Vapi, Valsad, Surat, Gandhidham, Kutch, Ankleshwer, Bharuch, Mumbai, Nashik, Pune, Thane, Aurangabad, Satara, Sangli, Nagpur, Kolhapur, Indore, Dewas, Bhopal, Chennai, Coimbatore, Selam and all over India.

Precision Engineering and Materials

Manufactured using premium materials like cast iron, ductile iron, stainless steel, and more, our double flange butterfly valves deliver superior durability and chemical resistance. The disc and seat combinations are tailored to accommodate a wide spectrum of media and temperatures, ensuring reliable performance and extended service life.

Versatile Applications and Connection Standards

Suitable for water, oil, gas, and chemicals, these valves support a variety of industrial and commercial uses. With double flanged connections conforming to ISO 2531/IS 1538, and face-to-face dimensions as per IS 5163/EN 558, our valves ensure seamless integration into existing pipeline systems.

Easy Operation and Dependable Sealing

Equipped with gear, lever, or motorized controls, the valves are designed for low-torque, effortless operation. High-quality seats and zero-leakage sealing (Class VI) guarantee effective shutoff and safety, meeting stringent pressure tests for your peace of mind.

FAQs of Double Flange Butterfly Valve Manufacturer in Gandhinagar:

Q: How is the double flange butterfly valve operated, and what configurations are available?

A: Our double flange butterfly valves can be operated manually with a lever or gear, or automatically using an electric or pneumatic actuator. This flexibility allows the product to be suited for both small- and large-diameter pipelines, as well as various remote or automated control systems.Q: What are the valves construction materials, and how do they benefit performance?

A: The valve discs are available in cast iron, SS304, SS316, ductile iron, and aluminum bronze, paired with seats made of EPDM, nitrile rubber, or PTFE. These combinations provide excellent resistance to corrosion, wear, and a wide range of chemicals and temperatures, accommodating diverse operating environments.Q: Where can these butterfly valves be used most effectively?

A: These valves are ideal for water treatment plants, HVAC systems, plumbing, industrial pipelines, and chemical processes. Their robust construction and versatile media compatibility make them suitable for use with water, oil, gas, and numerous chemicals within -10C to 120C.Q: What industry standards do the valves comply with?

A: Our double flange butterfly valves adhere to ISO 2531/IS 1538 for flanged end connections, IS 5163/EN 558 for face-to-face dimensions, and meet testing requirements with body pressures 1.5 times rated and seat pressures 1.1 times rated, ensuring reliability and safety.Q: How does the valve ensure zero leakage and low friction during operation?

A: Advanced seat designs in EPDM, nitrile rubber, or PTFE provide tight shutoff with zero leakage (Class VI rating). The high-quality surface finish and precision tolerances minimize friction, resulting in easier manual or automated operation and consistent performance.Q: What is the typical process to install or mount these valves?

A: Each valve features a double-flanged structure for secure bolted connections and includes an ISO 5211 top flange for direct actuator mounting, supporting quick, precise installation within new or existing pipeline networks.Q: What are the key benefits of choosing these valves for industrial applications?

A: Choosing our double flange butterfly valves assures reliable sealing, versatile operation, high resistance to chemicals and corrosion, easy installation, and long operational life, making them a cost-effective and high-performance solution for critical pipeline management needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

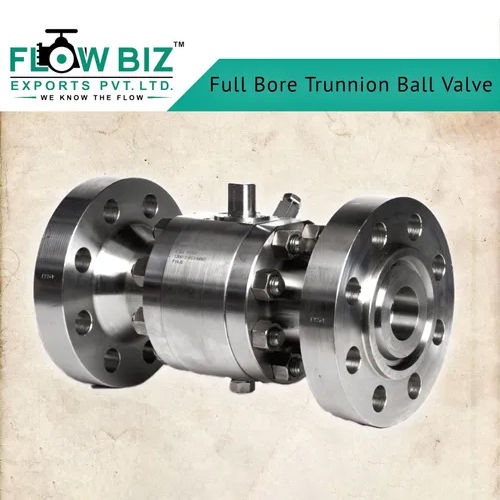

More Products in Ball Valve Category

Trunnion Mounted Ball Valve Manufacturer in Pune

Price 1700 INR / Unit

Minimum Order Quantity : 1 Number

Material : Other, Carbon Steel, Stainless Steel, Alloy Steel

Application : Industrial, Chemical, Oil & Gas, Petrochemical

Finish : Anticorrosive Paint / Powder Coated

Media : Other, Water, Oil, Gas, Chemical

Trunnion Mounted Ball Valve Manufacturer in Surat

Price 2500 INR / Unit

Minimum Order Quantity : 1 Number

Material : Other, Carbon Steel, Stainless Steel, Alloy Steel

Application : Petrochemical, Oil & Gas, Power, Water Treatment

Finish : Painted / Coated

Media : Other, Water, Oil, Gas

Wafer Type Jacketed Ball valve Manufacturer in Rajkot

Price 2000 INR / Unit

Minimum Order Quantity : 1 Number

Material : Other, Cast Steel / Stainless Steel / Carbon Steel

Application : Pharmaceutical, Chemical, Textile, Oil & Gas, Food Processing

Finish : Jacketed, Anticorrosive coated

Media : Other, Steam, Oil, Water, Gas, Chemical

Stainless Steel Full Bore Ball Valve

Price 2500 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Application : Industrial

Finish : Polished

Media : Gas

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free