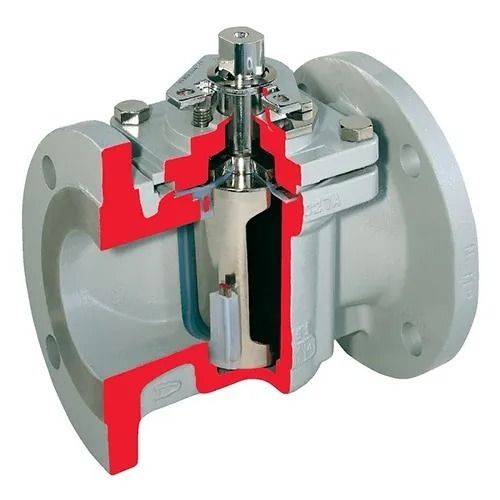

AUDCO Regular Pattern Plug Valve

Price 9000 INR/ Unit

AUDCO Regular Pattern Plug Valve Specification

- Application

- Industrial, Chemical, Oil & Gas, Petrochemical, Water Treatment

- Sealing

- Sleeved (PTFE/Elastomer), Metal-to-Metal

- Connection

- Flanged (ANSI, DIN, IS standards), Screwed Ends, Socket Weld

- Size

- 15 mm to 300 mm (1/2 to 12)

- Material

- Cast Iron, Carbon Steel, Stainless Steel, Bronze (varies by model)

- Valve Structure

- Regular Pattern, Cylindrical Taper Plug

- Media

- Water, Oil, Gas, Steam, Chemical Fluids

- Temperature of Media

- Up to 232C (450F) depending on material and trim

- Weight

- Varies by size (e.g., 7 kg to 150 kg)

- Dimension (L*W*H)

- Depends on size; conforms to standard face-to-face dimensions

- Power Mode

- Manual (Handwheel/Lever Operated)

- Bonnet Type

- Bolted or Screwed Bonnet

- Pressure Rating

- Class 150 to 600, PN 10/16, up to 40 bar

- Mounting

- ISO 5211 mounting pad for actuator, on request

- End-to-End Dimension

- ASME B16.10, IS 6157

- Stem Type

- Blow-out Proof Stem

- Fire Safe Design

- Optional fire safe tested models available

- Antistatic Device

- Available on request

- Plug Material

- Matching body or high-grade alloy as required

- Standards

- Manufactured per API 599, BS 5157, IS 3464

- Body Coating

- Epoxy Painted, Corrosion Resistant Coating

- Leakage Class

- Class VI for soft seated, Class V for metal seated

- Flow Characteristic

- Full Bore/Reduced Bore available

- Inspection & Testing

- As per API 598/BS 6755

- Operation

- Quarter Turn, Non Lubricated

About AUDCO Regular Pattern Plug Valve

Specification:

The face-to-face dimensions of these valves conform to BS1735 for class 125 Cast Iron Gate Valves. Class 125 flange dimensions and drilling under ANSI B 16.1. BSPT "D" flanges and preparing under BS10 except sizes 8" - 12" Flanges drilled unless otherwise stated on order.

Some holes in each flange are tapped and require studs of the same diameter as the bolts, which they replace. These flanged are integral to the valve body and have class 125 diameters.

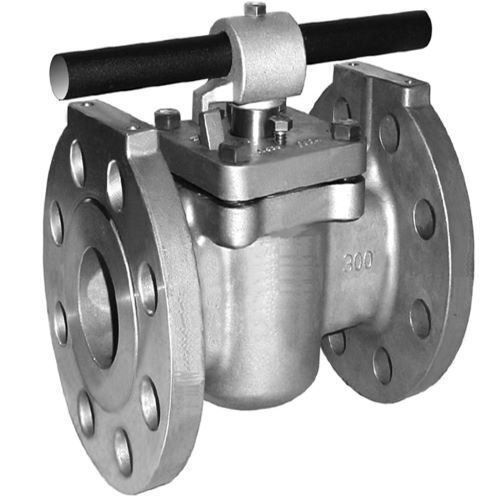

Product Name: AUDCO CI Plug Valve (Wrench Operated)

Figure Number: LW11 / LW13

Size Range: 2 Inch to 8 Inch (50mm to 200mm)

Pressure Rating: 175 Max Working Pressure

Material: Cast Iron

End Connection: Flanged End

Product Name: AUDCO CI Plug Valve (Worm Gear)

Figure Number: LG11 / LG13

Size Range: 2 Inch to 8 Inch (50mm to 200mm)

Pressure Rating: 175 Max Working Pressure

Material: Cast Iron

End Connection: Flanged End

Robust and Reliable Construction

Engineered for durability, the AUDCO Regular Pattern Plug Valve comes in a range of robust materials such as cast iron, carbon steel, stainless steel, and bronze. The epoxy-painted and corrosion-resistant body ensures longevity and reduced maintenance, even in harsh environments. Optional fire-safe designs and antistatic features meet demanding industry requirements, enhancing operational safety and reliability for end-users.

Performance and Versatility

This valve accommodates a wide spectrum of media-including water, oil, gas, steam, and chemicals-handling temperatures up to 232C (450F) depending on material selection. It is suitable for both full bore and reduced bore applications, aligning with various industrial standards. The plug's cylindrical taper and blow-out proof stem guarantee secure, efficient operation across pressures up to 40 bar.

Quality Assured By International Standards

With manufacturing conforming to API 599, BS 5157, IS 3464, and testing per API 598/BS 6755, this valve ensures high performance and reliable service. The ASME B16.10 and IS 6157 face-to-face dimensions guarantee compatibility and ease of installation, meeting both local and international specifications for seamless replacement and integration.

FAQ's of AUDCO Regular Pattern Plug Valve:

Q: How does the AUDCO Regular Pattern Plug Valve operate?

A: The valve operates with a quarter-turn movement using a handwheel or lever, providing quick opening and closing. Its non-lubricated design ensures smooth plug rotation, minimizing maintenance requirements and ensuring reliable performance in demanding industrial settings.Q: What are the available sealing options for this plug valve?

A: Sealing options include sleeved seals (PTFE/elastomer) for soft seating, delivering Class VI leakage, and metal-to-metal for more severe service conditions, offering Class V leakage. These options provide tailored sealing solutions depending on your process.Q: When should a fire-safe tested model be selected?

A: A fire-safe tested model is recommended when the application involves hazardous or flammable media, as it offers enhanced protection in the event of a fire. These models comply with recognized fire safety standards, reducing risk during emergencies.Q: Where can this plug valve be used?

A: The valve is suitable for installations in industrial, chemical, petrochemical, oil & gas, and water treatment plants, managing a variety of fluids including water, oil, gas, steam, and chemicals across diverse temperature and pressure ranges.Q: What is the process for ensuring valve quality and compliance?

A: Each valve is manufactured and tested according to international standards such as API 599, BS 5157, IS 3464, and undergoes inspection and pressure testing conforming to API 598 or BS 6755. This rigorous process ensures top-tier performance and operational reliability.Q: How can the valve be automated for remote operation?

A: Models with an ISO 5211 mounting pad allow for actuator installation, enabling automation or remote control of valve operations. This feature is available on request and supports smooth integration with control systems in modern facilities.Q: What benefits does the corrosion-resistant coating provide?

A: The corrosion-resistant epoxy coating significantly extends the valve's service life by shielding it against moisture, chemicals, and other corrosive agents. This protection reduces the frequency of maintenance and replacement, lowering total ownership cost.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plug Valve Category

Lubricated Plug Valves

Price 3000 INR / Unit

Minimum Order Quantity : 1 Number

Size : 1/2 to 24 (DN15 to DN600)

Material : Other , Carbon Steel, Stainless Steel, Cast Iron

Valve Structure : Other, ThreePiece Body or Lubricated Plug Design

Plug Valve Manufacturer In Patan

Price 2000 INR / Unit

Minimum Order Quantity : 1 Number

Size : Standard Sizes

Material : Stainless Steel

Valve Structure : Plug Valve

Usage : Industrial

Double Block and Bleed Valve Manufacturer in Vapi

Price 1100.00 INR / Unit

Minimum Order Quantity : 1 Number

Size : Standard

Material : Cast Iron

Valve Structure : Plug Valve

Usage : Industrial

Sleeved Plug Valves Manufacturer in Rajkot

Price 500.00 INR / Unit

Minimum Order Quantity : 1 Number

Size : 1/2"16

Material : Stainless Steel

Valve Structure : Plug Valve

Usage : Industrial

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free