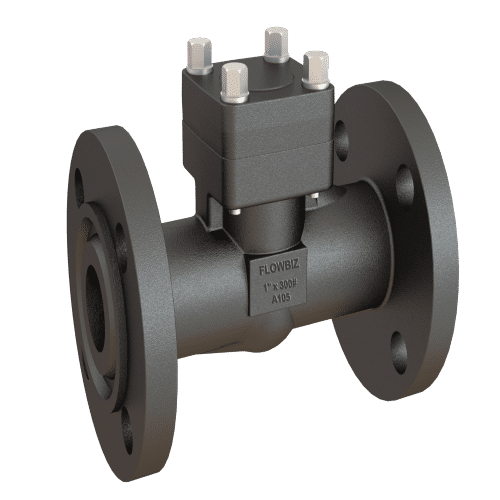

AUDCO (LnT) Make Swing Check Valve

Price 6000 INR/ Unit

AUDCO (LnT) Make Swing Check Valve Specification

- Valve Type

- Check Valve

- Features

- High flow capacity, full bore, tight sealing, self-actuating, rugged construction

- Material

- Cast Iron, Ductile Iron, Carbon Steel, Stainless Steel, Alloy Steel

- Valve Size

- 15 mm to 600 mm

- Connection Type

- Flanged (as per ANSI/ASME B16.5, B16.47)

- Sealing

- Metal-to-Metal or Soft Seated (as per application)

- Application

- Industrial pipeline systems, water, oil & gas, chemical, steam and process applications

- Structure

- Swing type

- Type

- Swing Check Valve

- Power

- Manual (Non-actuated)

- Pressure

- Class 150, 300, 600, 900, 1500, 2500 (ASME)

- Media

- Liquids, Gases, Steam, Oil

- Port Size

- 15 mm to 600 mm (1/2 to 24)

- Temperature

- -10C to 220C (Depending on material & class)

- Disc

- Single disc, swing type

- Pin

- Stainless Steel or Alloy Steel (as per design)

- Flow Direction

- Unidirectional

- Hydrostatic Test Pressure

- As per ASME / API 598

- Seat Material

- Metallic (13% CR, SS), soft seat optional

- Industry Certifications

- PED, ISO9001 on request

- Weight

- Varies with size and material

- Design Standard

- API 6D / BS EN ISO 14341

- Service Life

- Long service with low maintenance

- PN Rating

- PN16, PN25, PN40 on request

- Body Finish

- Epoxy coated or painted as per project specification

- Testing Standard

- API 598

- Face-to-Face Dimensional Standard

- ASME B16.10

- Operation

- Non-return, prevents backflow

- Mounting Position

- Horizontal or Vertical installation

- Packing

- Standard export packaging

- Gasket

- Spiral Wound / Metal / Non-metallic (as per material)

- End Connection Standard

- ANSI/ASME B16.5, B16.47

- Top Cover

- Bolted cover

About AUDCO (LnT) Make Swing Check Valve

AUDCO (L&T) Make Swing Check Valve (NRV)

Design Standard: BS 1868

Design Type: Check Valve Bolted Cover Swing type Disc

Size Range: 2 inches to 12 inches (50mm to 300mm)

Material of construction: WCB / WC6 / WC9 / LCB / LCC / CF8 / CF8M

End Connection: Flanged End / Buttweld End

Pressure Rating: ASA 150# to ASA 1500#

Testing Standard: API 598

Versatile, High-Performance Design

The AUDCO (LnT) Swing Check Valve boasts a full bore design for optimal flow capacity, coupled with a rugged swing-type construction and bolted top cover. Its epoxy-coated or project-specified finish enhances corrosion resistance, ensuring longevity and reliable performance in demanding industrial environments. This valve is suitable for both horizontal and vertical installations, offering flexibility to match site requirements.

Comprehensive Standards and Certifications

Engineered in adherence to stringent international standards-ANSI/ASME B16.5, B16.47, API 6D, ASME B16.10, and API 598-the valve maintains product integrity across pressure classes (PN16, PN25, PN40, Class 150-2500 ASME). Optional certifications such as PED and ISO9001 are available, underscoring commitment to global quality benchmarks and safety protocols.

Reliable, Low-Maintenance Operation

This swing check valve is designed for extended service life with minimal upkeep, thanks to self-actuating, non-return operation and robust materials. The single swing disc ensures quick response and effective backflow prevention, while high-quality gaskets and seat materials (metallic or soft) provide superior sealing for a wide range of liquids, gases, and steam.

FAQ's of AUDCO (LnT) Make Swing Check Valve:

Q: How does the AUDCO Swing Check Valve prevent backflow in a pipeline?

A: The valve employs a swing-type disc mechanism that allows fluid to flow in one direction only. If the flow reverses, the disc closes automatically, preventing any backflow and safeguarding your system.Q: What are the available end connection and design standards for this valve?

A: This swing check valve is designed and manufactured following ANSI/ASME B16.5 or B16.47 for flanged connections and meets API 6D or BS EN ISO 14341 for design, ensuring interoperability and compliance with international piping practices.Q: Where can the AUDCO Swing Check Valve be installed within an industrial system?

A: The valve can be installed in both horizontal and vertical pipeline orientations, making it suitable for a wide range of process systems including water, oil & gas, chemical, steam, and general process lines.Q: What pressure and temperature ranges does this valve support?

A: Depending on the material and class, the valve accommodates pressure ratings from PN16 to PN40 (or ASME Class 150-2500), and operates efficiently in temperatures from -10C to 220C.Q: How is the valve tested for quality and reliability?

A: Each valve undergoes rigorous hydrostatic and seat leakage testing in accordance with API 598 and ASME standards to ensure safe and leak-free operation in demanding industrial settings.Q: What are the main benefits of using this swing check valve in a process application?

A: The key benefits include high flow capacity, tight and reliable sealing, self-actuating non-return operation, long service life with low maintenance, and suitability for a broad range of media and applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Check Valve Category

Swing Flex Check Valves

Price 4500 INR / Unit

Minimum Order Quantity : 1 Number

Type : Swing Flex Check Valve

Application : Suitable for potable water, sewage, wastewater, fire protection, and industrial applications.

Disc : Ductile Iron with EPDM/NBR encapsulation

Media : Other, Water, sewage, noncorrosive fluids

Lift Check Valve Manufacturer in Rajkot

Price 500 INR / Unit

Minimum Order Quantity : 1 Number

Type : Flanged End, Screwed End

Application : Industrial pipeline systems, water supply, chemical processing, oil & gas refineries

Disc : Stainless Steel / Brass / Bronze

Media : Other, Water, Oil, Steam, Air, Gas

Lift Check Valve Manufacturer in Surat

Price 2000 INR / Unit

Minimum Order Quantity : 1 Number

Type : Check Valve

Application : Fluid control

Disc : Swing Disc

Media : Other, Liquid or Gas

Inline Check Valve Manufacturer Gandhidham

Price 2000 INR / Unit

Minimum Order Quantity : 1 Number

Type : Inline check valve

Application : Suitable for water, oil, gas and process industries

Disc : Stainless Steel

Media : Other, Liquid, Gas

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free