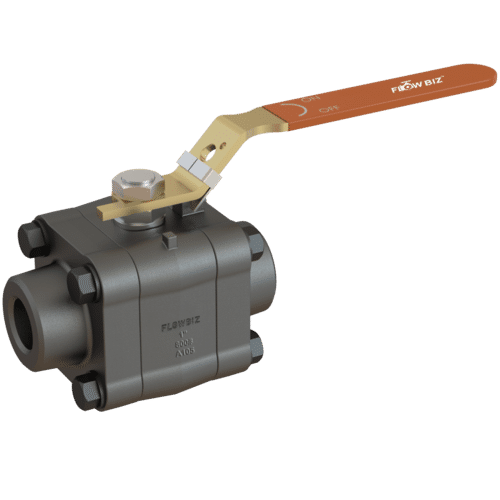

400 - 600 -1000 WOG Ball Valves Manufacturer in Mumbai

Price 2000 INR/ Unit

400 - 600 -1000 WOG Ball Valves Manufacturer in Mumbai Specification

- Caliber

- Standard

- Channels

- 2 Way, 3 Way

- Connection

- Screwed, Flanged, Welded

- Pressure

- 400 WOG, 600 WOG, 1000 WOG

- Structure

- Ball

- Material

- Stainless Steel, Carbon Steel, Brass

- Power

- Manual

- Media

- Water, Oil, Gas

- Temperature of Media

- -20C to 200C

- Port Size

- 1/2 inch to 4 inch

- Flange

- ANSI, DIN, BS Standard

- Finish

- Polished, Sand Blasted

- Application

- Industrial, Commercial, Residential

- Operation

- Quarter Turn

- Testing Standard

- API 598

- Body Material

- CF8, CF8M, WCB

- ISO Mounting Pad

- Available

- Blowout Proof Stem

- Yes

- Corrosion Resistance

- High

- End Connection

- Threaded / Flanged / Socket Weld

- Design Standard

- API 608, BS 5351

- Fire Safe Design

- Optional

- Leakage Rating

- Class VI

- Locking Device

- Available

- Seat Material

- PTFE, RPTFE, Metal

About 400 - 600 -1000 WOG Ball Valves Manufacturer in Mumbai

WOG - 3000 High-Pressure Ball Valve

FlowBiz (Water, Oil, and Gas) WOG Ball Valve series are low torque engineered for high-pressure applications. Features include live-loaded stem seals, replaceable seats and seals, and nickel plating on carbon steel bodies. Other body materials are available upon request threaded and extended socket welded connections.

Size Range: 1/2 inch to 2 inches (15mm to 50mm)

End Connection: Screwed End

Key Features:

- Full Port / Bore.

- Grounded Ball and Stem

- As per NACE MR0175

- As per API 607 Locking & Spring Return Lever.

- Threaded Ends to ASME B1.20.1

FlowBiz is the best manufacturer of WOG Ball valves in India. We supply WOG Ball Valve in Ahmedabad, Vapi, Valsad, Surat, Gandhidham, Kutch, Ankleshwer, Bharuch, Mumbai, Nashik, Pune, Thane, Aurangabad, Satara, Sangli, Nagpur, Kolhapur, Indore, Dewas, Bhopal, Chennai, Coimbatore, Selam and all over India.

Versatile Design Meets Stringent Standards

Our ball valves comply with international standards like API 608, BS 5351 for design, and API 598 for testing, ensuring uncompromised safety and performance. With end connections available in threaded, flanged, and socket weld types, these valves are suitable for a broad range of applications, accommodating different piping systems and installation environments.

Superior Durability and Corrosion Resistance

Constructed from CF8, CF8M stainless steel, or WCB carbon steel, our ball valves endure tough environments. Their corrosion-resistant bodies and optional fire-safe design make them ideal even under challenging operating conditions, while PTFE, RPTFE, and metal seat options promise low maintenance and long service life.

FAQ's of 400 - 600 -1000 WOG Ball Valves Manufacturer in Mumbai:

Q: How do I select the appropriate ball valve model for my specific application?

A: Choosing the right ball valve depends on your system's media (water, oil, or gas), pressure rating (400, 600, or 1000 WOG), temperature range (-20C to 200C), and end connection style (threaded, flanged, socket weld). Consider seat and body material based on required corrosion resistance and application environment. Our expert team in Mumbai can guide you through the selection process.Q: What are the benefits of the blowout-proof stem and fire-safe design?

A: A blowout-proof stem increases operational safety by preventing accidental stem ejection under pressure. The optional fire-safe design adds a layer of protection, ensuring valve integrity and tight shut-off even in high-temperature incidents, making these valves suitable for demanding industrial applications.Q: When is a locking device or ISO mounting pad necessary for ball valves?

A: A locking device is recommended when operational security is critical, such as in public or high-security facilities, to prevent accidental or unauthorized operation. An ISO mounting pad is useful when automation is anticipated, allowing quick and easy mounting of actuators for remote or automated process control.Q: Where are these ball valves typically installed?

A: These ball valves are versatile and suitable for use in industrial plants, commercial buildings, or residential piping systems. They are designed for installation wherever reliable shut-off or flow control of water, oil, or gas is needed, adhering to ANSI, DIN, or BS standards depending on project requirements.Q: What advantages do PTFE, RPTFE, and metal seats offer?

A: PTFE and RPTFE seats deliver excellent chemical and temperature resistance, ensuring tight sealing and low maintenance. Metal seats are ideal for high-temperature or abrasive services, offering durability in challenging conditions. We provide seat material options to match diverse application needs.Q: How are your ball valves tested before shipment?

A: Each valve undergoes rigorous pressure and leakage testing according to API 598 standards. This ensures every product meets the highest safety and performance benchmarks before reaching customers, providing confidence in reliability and quality.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Ball Valve Category

Forged Steel Ball Valve Manufacturer in Kheda

Price 800 INR / Unit

Minimum Order Quantity : 1 Number

Media : Other, Water, Oil, Gas

Material : Other, Forged Steel

Application : Industrial Pipelines, Chemical Plants, Refineries

Finish : AntiCorrosive Coating

High Pressure Ball Valve Manufacturer in Vadodara

Price 2000 INR / Unit

Minimum Order Quantity : 1 Number

Media : Other, Water, Oil, Gas, Chemical

Material : Other, Stainless Steel / Carbon Steel

Application : Industrial, Chemical, Petrochemical, Oil & Gas

Finish : Polished or Painted

Ball Valve Manufacturer Patan

Price 5000 INR / Unit

Minimum Order Quantity : 1 Number

Media : Water

Material : Other, Cast Iron

Application : Industrial

Finish : Painted

Gear Operated Ball Valve

Price 4500 INR / Unit

Minimum Order Quantity : 1 Unit

Media : Gas

Material : Brass

Application : Industrial

Finish : Polished

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free