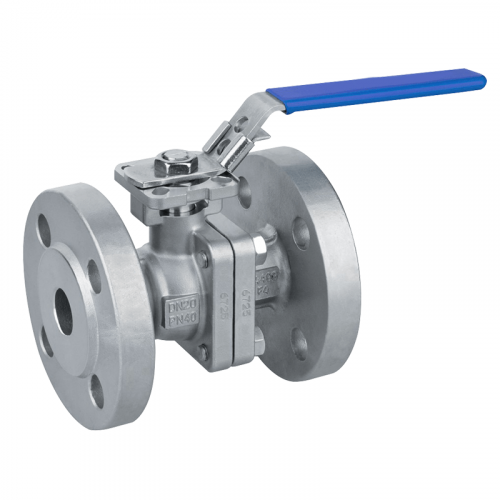

WOG Ball Valve Manufacturer in Gandhidham

Price 2000 INR/ Unit

WOG Ball Valve Manufacturer in Gandhidham Specification

- Connection

- Flanged / Screwed

- Pressure

- Up to 1000 WOG

- Caliber

- Standard

- Channels

- Two-way

- Structure

- Ball

- Material

- Stainless Steel

- Power

- Manual

- Media

- Water, Oil, Gas

- Temperature of Media

- Medium Temperature

- Port Size

- 15mm to 100mm

- Flange

- Yes

- Finish

- Polished

- Application

- Industrial, Petrochemical, Water Treatment

- Testing Standard

- API 598

- Operation Type

- Quarter Turn

- Body Material Grade

- SS304/SS316

- Locking Arrangement

- Optional

- Anti-Static Device

- Yes

- End Connection

- BSP / NPT

- Seal

- PTFE Seat

- Handle Material

- Stainless Steel with PVC Sleeve

- Mounting Pad

- ISO 5211

- Fire Safe Design

- Available Upon Request

- Face to Face Dimension

- As per ANSI B16.10

- Leakage Class

- ANSI B16.104 Class VI

About WOG Ball Valve Manufacturer in Gandhidham

WOG - 3000 High-Pressure Ball Valve

FlowBiz (Water, Oil, and Gas) WOG Ball Valve series are low torque engineered for high-pressure applications. Features include live-loaded stem seals, replaceable seats and seals, and nickel plating on carbon steel bodies. Other body materials are available upon requestthreaded and extended socket welded connections.

Size Range: 1/2 inch to 2 inches (15mm to 50mm)

End Connection: Screwed End

Key Features:

Full Port / Bore.

Grounded Ball and Stem

As per NACE MR0175

As per API 607 Locking & Spring Return Lever.

Threaded Ends to ASME B1.20.1

FlowBiz is the best manufacturer of WOG Ball valves in India. We supply WOG Ball Valve in Ahmedabad, Vapi, Valsad, Surat, Gandhidham, Kutch, Ankleshwer, Bharuch, Mumbai, Nashik, Pune, Thane, Aurangabad, Satara, Sangli, Nagpur, Kolhapur, Indore, Dewas, Bhopal, Chennai, Coimbatore, Selam and all over India.

Precision Engineering for Industrial Demands

Our ball valves are manufactured in Gandhidham using premium-grade SS304/SS316, ensuring superb corrosion resistance and mechanical strength. Designed for up to 1000 WOG, these valves cater to demanding fluid control environments and are instrumental for water, oil, and gas handling. Optional fire safe design, anti-static device, and ISO 5211 mounting compatibility provide adaptability across diverse industries.

Versatile Design and Rigorous Standards

Engineered to surpass stringent industry standards, the valve's PTFE seats guarantee minimal leakage while its quarter-turn operation facilitates smooth and fast flow control. All products are tested as per API 598, with dimensions standardized to ANSI B16.10, ensuring compatibility and reliability for export and domestic supply.

FAQ's of WOG Ball Valve Manufacturer in Gandhidham:

Q: How does the quarter-turn operation of the ball valve benefit users?

A: The quarter-turn mechanism allows for rapid on/off flow control with minimal effort, enabling efficient operation even in demanding industrial environments. This design also reduces actuator wear and supports automation processes.Q: What ensures leak-proof performance in your WOG ball valves?

A: The valves utilize PTFE seats and are tested to meet ANSI B16.104 Class VI leakage class standards. This guarantees an extremely tight seal and reliable performance in applications involving water, oil, and gas.Q: When should I opt for the fire safe design and locking arrangement features?

A: The fire safe design is recommended for applications where fire hazards are a concern, such as petrochemical and oil processing industries. The optional locking arrangement is suitable when controlled access and enhanced safety are required.Q: Where are these stainless steel ball valves commonly used?

A: These valves are widely installed in industrial systems, petrochemical plants, and water treatment facilities, where robust, corrosion-resistant valves are essential for safe and efficient operation.Q: What is the process for testing the valves before shipment?

A: Every valve undergoes rigorous quality testing in accordance with API 598 standards, including leakage and pressure tests, to ensure consistent reliability and compliance with international norms.Q: How do the PTFE seats and polished finish contribute to valve performance?

A: PTFE seats offer excellent chemical resistance and reduce friction, thus extending the valve's service life and ensuring optimal sealing. The polished stainless steel finish enhances durability and resists environmental degradation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Ball Valve Category

Ball Valve Manufacturer in India

Price 2400 INR / Unit

Minimum Order Quantity : 1 Number

Application : Industrial, Chemical, Oil & Gas, Water

Material : Stainless Steel

Media : Other, Water, Gas, Oil

Finish : Polished

Single Piece Ball Valve Manufacturer in Pune

Price 2400 INR / Unit

Minimum Order Quantity : 1 Number

Application : Industrial, Chemical, Petrochemical, Water Treatment

Material : Stainless Steel

Media : Other, Water, Oil, Gas

Finish : Polished

Single Piece Ball Valve Manufacturer in Gandhinagar

Price 500 INR / Unit

Minimum Order Quantity : 1 Number

Application : Industrial Flow Control

Material : Stainless Steel

Media : Water

Finish : Polished & Coated

Three Piece Ball Valve Manufacturers in Kheda

Price 1000 INR / Unit

Minimum Order Quantity : 1 Number

Application : Industrial

Material : Stainless Steel

Finish : Polished

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free