Wafer Type Damper Valve

Price 20000 INR/ Unit

MOQ : 1 Unit

Wafer Type Damper Valve Specification

- Material

- Cast Iron, Stainless Steel, Carbon Steel (Body and Disc)

- Valve Type

- Wafer Type Damper Valve

- Control System

- Manual Lever/Gear, Pneumatic Actuator, or Electric Actuator

- Valve Size

- DN50 to DN1200

- Connection Type

- Wafer Type Mounting between Flanges

- Features

- Lightweight Design, Compact, Quick Shutoff, Low Pressure Drop

- Voltage

- 24V, 110V, 220V AC/DC for Actuated Types

- Usage

- Industrial

- Structure

- Wafer Type, Circular Body, Centrally Mounted Disc

- Application

- HVAC, Ventilation, Industrial Process Control

- Sealing

- Soft Seated, Metal to Metal (Optional)

- Type

- Wafer Type Damper Valve

- Power

- Manual, Pneumatic, or Electric Operation

- Size

- Different Available

- Pressure

- 0.6 MPa to 1.6 MPa

- Media

- Air, Gases, Light Dust

- Product Type

- Damper Valve

- Port Size

- 50 mm to 1200 mm

- Color

- White

- Temperature

- Up to 200C (Depending on Material)

- Disc

- Mild Steel / Stainless Steel / Aluminium

- End Connection

- Wafer (Sandwiched Between Flanges)

- Shaft Material

- Stainless Steel

- Design Standard

- BS, ASTM, or Equivalent

- Body Coating

- Epoxy Coated or Painted for Corrosion Resistance

- Fire Safe Design

- Optional as per Application

- Maintenance

- Low Maintenance, Easy Disk Removal

- Service Life

- Over 50,000 Cycles under Standard Conditions

- Leakage Class

- Class III or IV (as specified)

- Drive Type

- Direct Mount, Bracket and Coupler for Actuators

- Seat Material

- EPDM, PTFE, or Metal

- Operation Position Indicator

- Available on Request

- Mounting Standard

- Compatible with ANSI, DIN, JIS Flange Standards

Wafer Type Damper Valve Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Week

- Delivery Time

- 5 Days

- Main Domestic Market

- All India

About Wafer Type Damper Valve

Wafer Type Damper Valve

Damper Butterfly Valves are suitable for applications where the leakage is not all-important. Damper Butterfly Valve is also the best option for isolating dampers for flue-gas scrubbers. FlowBiz Damper Butterfly Valves are lightweight, easy, rapidly actuated, and often inexpensive. The drive for a butterfly damper is also simple, requiring only 90 degree of motion.

Size Range: 11/2 inch to 20 inch

TEST PRESSURE:

TESTING: HYDRAULIC

BODY : 10KG/CM2

Leakage: 5per

Engineered for Endurance and Corrosion Resistance

This damper valve boasts a coated body-epoxy or paint-to maximize protection against corrosive environments. Designed for over 50,000 cycles and low maintenance, it suits demanding HVAC and industrial processes. The valve's lightweight, compact form factor ensures easy installation and minimal pressure drop.

Versatile Mounting and Operation

Compatible with ANSI, DIN, and JIS flanges, the wafer type damper valve fits seamlessly into varied piping systems. It supports a broad range of operation modes including manual, pneumatic, or electric actuators-offering flexibility for system upgrades and diverse industrial applications.

Precision Engineering and Trusted Standards

Built in accordance with BS, ASTM, or equivalent standards, this valve features precision-engineered seats (EPDM, PTFE, or metal) and stainless steel shafts for longevity. Optional fire-safe design and available operation position indicators cater to safety and process monitoring requirements.

FAQ's of Wafer Type Damper Valve:

Q: How does the wafer type damper valve resist corrosion in harsh environments?

A: The valve body is epoxy coated or painted, creating a protective barrier that shields against corrosion from air, gases, and environmental factors. This ensures durability and reliable performance, especially in industrial or HVAC installations.Q: What flange standards does the valve support for mounting?

A: This valve is compatible with ANSI, DIN, and JIS flange standards, allowing integration into a variety of piping systems commonly found in industries across India and worldwide.Q: When should I choose EPDM, PTFE, or metal seat materials for this valve?

A: Choose EPDM seats for general air or light dust, PTFE for chemical resistance, and metal seats for high-temperature or abrasive applications. Selection depends on the specific process media and operating conditions.Q: Where can the wafer type damper valve be used effectively?

A: Its design suits HVAC, ventilation, and industrial process control systems in environments handling air, gases, and light dust, with temperature capabilities up to 200C (depending on materials used).Q: What is the process for maintaining and servicing this valve?

A: The valve is designed for low maintenance. Its easy disk removal system allows for quick inspection and servicing, minimizing downtime and ensuring long service intervals.Q: How is the valve operated and controlled?

A: Options include manual lever/gear, pneumatic actuator, or electric actuator, with voltage choices of 24V, 110V, or 220V AC/DC for actuated types. Position indicators and brackets for actuators are available upon request.Q: What are the benefits of using this wafer type damper valve in industrial systems?

A: Key benefits include lightweight, compact design, quick shutoff, low pressure drop, and a long service life exceeding 50,000 cycles under standard conditions. Its versatile mounting and operation options enhance system flexibility and efficiency.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Damper Valve Category

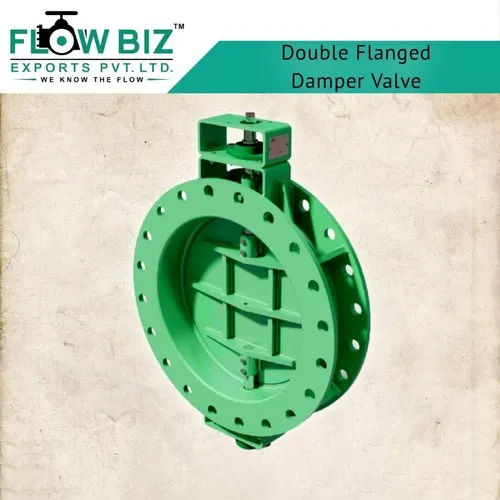

Double Flanged Wafer Damper Valve

Price 2100 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Industrial

Product Type : Wafer Damper Valve

Pressure : High Pressure

Media : Gas

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free