Triple Offset Butterfly Valve Manufacturer in Gandhidham

Price 2000.00 INR/ Unit

Triple Offset Butterfly Valve Manufacturer in Gandhidham Specification

- Connection

- Flanged

- Usage

- Industrial

- Material

- Cast Iron

- Size

- 1/2" to 12"

- Power Source

- Hydraulic

- Pressure

- Medium Pressure

- Media

- Water, Gas , Air , Oil

- Working Temperature

- Medium Planck temperature ()

- Color

- Red

- Shape

- Round

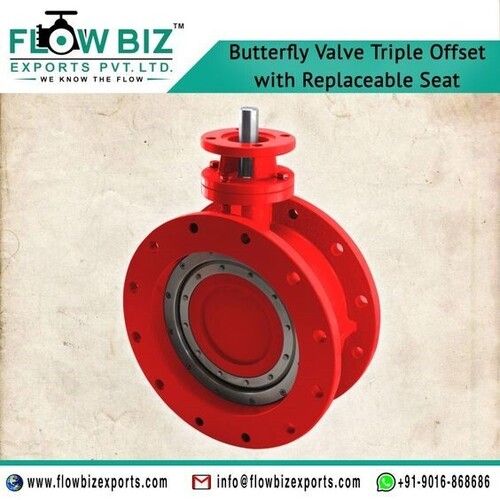

About Triple Offset Butterfly Valve Manufacturer in Gandhidham

The Triple offset butterfly valve has three separate offsets. Two balances are at the base, and the third offset is on the sealing surface, making a cone-like form of the disk and the seat. Triple offset valves are operated where a bubble-tight seal is needed, the method is under high temperature, and difficult sealing with zero leakage is required.

The first offset:is provided to the central axis of the sealing surface, in which the disc rotates 360 degrees around the middle axis to provide sealing by bending the soft seal, which results in total variance.

The second offset:refers to the part of the pole for the bores centerline. At the time of the procedure, it produces a cam activity to lift the seat away from the seal, resulting in friction during the first 10 degrees of opening and the last 10 degrees of closing.

The third offsetis the closing elements. Each sealing part is machined into a conical offset shape, which results in a right-angled cone. Throughout its working cycle, this ensures friction-free stroking. Connection is only made with the 90 angle functioning as an automatic stop at the last point of closing; this results in no over-travel of the disc seat.

When these three offsets are provided together, the Valve offers a continuous sealing surface, shows the tiniest wear between sealing surfaces, and provides long-lasting sealing throughout the Valves life. In addition, the bonding and binding of the disk are reduced, and less operating circulatory is needed as it has an optimized seating angle.

Classification by Connection Type:

Based on the connection, there are additional types of Triple offset butterfly valves.

- Wafer-type ends.

- Lug-type ends.

- Both flanged ends.

- Butt-welded types end.

Precision Engineering for Industrial Applications

Our triple offset butterfly valves are crafted with exceptional attention to detail, ensuring optimal sealing and minimal leakage. The advanced triple offset design guarantees excellent performance in demanding industrial environments, handling a range of media under medium pressure and temperature conditions, with hydraulic actuation for enhanced control.

Versatile Solutions from Gandhidham, India

As a trusted manufacturer, exporter, supplier, and trader, we provide round, red triple offset butterfly valves to customers across India and beyond. The flanged connections make installation straightforward, and the durable cast iron construction ensures longevity and reliable operation in various sectors.

FAQs of Triple Offset Butterfly Valve Manufacturer in Gandhidham:

Q: How does the triple offset design benefit the valves performance in industrial settings?

A: The triple offset design ensures tight shutoff and minimal friction during operation, which enhances sealing performance. This allows the valve to handle demanding industrial conditions reliably while minimizing leakage and wear.Q: What is the process for installing a triple offset butterfly valve with a flanged connection?

A: Installation involves aligning the valves flange with the pipeline, securing it with appropriate bolts, and ensuring proper sealing to prevent leaks. The flanged connection simplifies the process and facilitates easy maintenance.Q: When should I use this valve for medium pressure applications?

A: Our triple offset butterfly valves are ideal for medium pressure environments where loose sealing or excessive wear could compromise process integrity. Their robust construction and hydraulic actuation make them suitable for sustained industrial use.Q: Where can these butterfly valves be utilized within my facility?

A: These valves are versatile and can be installed in any section of your facility where water, gas, air, or oil flow needs precise control, such as in distribution lines, isolation zones, or system inlets and outlets.Q: What are the advantages of using cast iron material for this valve?

A: Cast iron offers high durability and corrosion resistance, making the valve suitable for rigorous industrial operations. Its strength ensures safe and reliable functioning even under medium pressure and varying temperature conditions.Q: How does the hydraulic power source improve valve operation and control?

A: Hydraulic actuation provides powerful and precise valve movement, allowing for smooth operation even in larger valve sizes. It also reduces manual effort and improves response time in critical applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Butterfly Valve Category

PTFE Lined Butterfly Valve Manufacturer in India

Price 3000 INR / Unit

Minimum Order Quantity : 1 Number

Power Source : Other, Manual, Pneumatic, Electric

Material : Other, PTFE Lined (Body: Ductile Iron/Cast Iron/Carbon Steel/SS 304/SS 316)

Butterfly Valve Manufacturer in Vapi

Price 3100.00 INR / Unit

Minimum Order Quantity : 1 Number

Power Source : Hydraulic

Material : Stainless Steel

Color : Blue

Size : 1/2" to 12"

Butterfly Valve Manufacturer In Narmada

Price 5000.00 INR / Unit

Minimum Order Quantity : 1 Number

Power Source : Manual

Material : Stainless Steel

Color : Blue

Size : Standard

Double Flange Fabricated Damper Valve Manufacturer in Jamnagar

Price 900 INR / Unit

Minimum Order Quantity : 1 Number

Power Source : Electrical

Material : Stainless Steel

Color : Silver

Size : All size

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free