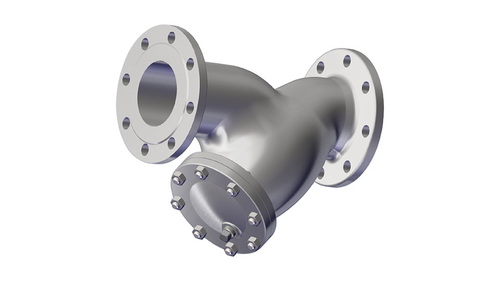

Strainer Manufacturers in Ahmedabad

Price 3000 INR/ Unit

Strainer Manufacturers in Ahmedabad Specification

- Features

- Durable construction Easy maintenance

- Connection Type

- Flanged

- Material

- Cast iron

- Control System

- Manual

- Valve Size

- 2 inches

- Structure

- Y-type

- Application

- Liquid filtration

- Sealing

- Rubber gasket

- Type

- Y-strainer

- Pressure

- Up to 10 bar

- Media

- Water Oil

- Port Size

- 2 inches

- Temperature

- Up to 150C

- Disc

- Perforated metal

- Pin

- Standard steel pins

About Strainer Manufacturers in Ahmedabad

FlowBiz Valves is a High Quality Strainer Manufacturers in Mumbai, Maharashtra, India. We are a leading manufacturer of Ball Valves in Mumbai and all nearby areas.

- SIZES: 15mm to 350mm

- TYPE: Weir, straight through, Basket, "y Type

- END CONNECTION : Conforming BS-5156 flanged to ANSI B-16.1 Class 125/150 lbs, DIN-3202-F1, PN-10/PN-16

- PRESSURE RATING ASA : 150 #, 300#, 600#

- WIDELY USED FOR: Sugar mill, Marine & Mining, Distillery Plant, Fertilizer Plant, Pulp & Paper mill, Industrial Chemical Piping, Oil, Gas, Petrochemical Plant, Textile and Process Industries, Thermal and Nuclear Power Plant

APPLICABLE STANDARD:

- Manufacturing Standard: ASME B16.34

- Inspection And Testing Standard: API 598

- Pressure-Temperature Rating: ASME B 16.34

- Flanged End Dimension: ASME B 16.5

- Butt Weld Standard: ASME B 16.25

- Face to Face Dimension : ASME B 16.10

Robust Construction for Versatile Applications

Our Y-type strainers offer durable cast iron construction with perforated metal discs, making them ideal for a range of liquid filtration requirements involving water and oil. Designed for pressures up to 10 bar and temperatures up to 150C, they provide reliable, long-term service. Enhanced with rubber gaskets and standard steel pins, they are suitable for industrial processes requiring optimal filtration efficiency.

User-Friendly Maintenance and Operation

These strainers are engineered for easy manual operation and simple maintenance. With their flanged connection and accessible structure, regular cleaning and component replacement become straightforward tasks, reducing downtime and maintenance costs. Their compact, user-centric design makes them a preferred choice across industrial domains.

FAQ's of Strainer Manufacturers in Ahmedabad:

Q: How do Y-type strainers from Ahmedabad manufacturers function in liquid filtration?

A: Y-type strainers use a perforated metal disc to remove debris and particles from water and oil as the fluid passes through the strainer body. This design protects downstream equipment and ensures a smoother filtration process.Q: What materials are used in these Y-strainers and why?

A: These Y-strainers are made from cast iron for the main body, with a perforated metal disc for filtration and standard steel pins. The choice of these materials ensures durability, resistance to corrosion, and efficient contaminant removal in demanding industrial environments.Q: When should I use a 2-inch Y-type strainer in my liquid handling system?

A: A 2-inch Y-type strainer is ideal for pipelines of the same nominal size, particularly where the filtration of water or oil is critical to maintaining equipment performance and protecting sensitive machinery from particulate damage.Q: Where can these Y-strainers be installed?

A: These Y-type strainers can be installed in various liquid transport systems, especially in industries located in Ahmedabad or across India. They are suitable for any system requiring reliable water or oil filtration at pressures up to 10 bar and temperatures up to 150C.Q: What is the process for cleaning and maintaining these strainers?

A: Maintenance is straightforward due to the strainer's accessible structure. Simply isolate the strainer, open the cover, remove the perforated disc for cleaning, replace the rubber gasket if necessary, and reassemble to restore optimal operation.Q: How does the manual control system enhance strainer usability?

A: A manual control system allows operators to easily inspect and maintain the strainer by quickly shutting off flow and accessing internal components, making it both efficient and user-friendly.Q: What benefits do these Y-type strainers offer over other designs?

A: These Y-type strainers provide superior durability, easy maintenance, high filtration efficiency, and adaptability to both water and oil. Their robust construction and flanged connections make them well-suited for industrial use, ensuring long-term reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in strainer Category

Conical Type Strainer Manufacturer In Jamnagar

Price 800 INR / Unit

Minimum Order Quantity : 1 Number

Material : Stainless Steel, Brass, Carbon Steel, as required

Features : Corrosion Resistant, Durable, Easy Installation

Usage : Construction

Color : Silver

Duplex Strainer Manufacturer in Surat

Price 4000 INR / Unit

Minimum Order Quantity : 1 Number

Material : MS

Features : Good Quality

Usage : Industrial

Color : Blue

Strainer Valve Manufacturers in Gandhinagar

Price 800 INR / Unit

Minimum Order Quantity : 1 Number

Material : SS

Features : Good Quality

Usage : Industrial

Color : Silver

T Strainer Manufacturer in Surat

Price 3000 INR / Unit

Minimum Order Quantity : 1 Number

Material : MS

Features : Good Quality

Usage : Industrial

Color : Blue

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free