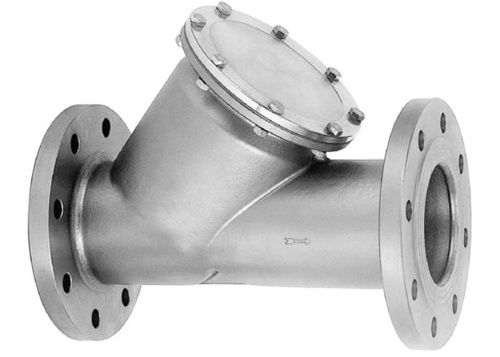

SPIRAX Marshall Y type Strainer

Price 6000 INR/ Unit

SPIRAX Marshall Y type Strainer Specification

- Bend Radius

- Not applicable for strainer

- Sealing Type

- Gasket Seal

- Yield Strength

- 240 MPa (Min)

- Tensile Strength

- 440 MPa (Min)

- Diameter

- As per pipe size (15mm to 300mm NB)

- Tolerance

- 0.5 mm

- Flexibility

- Rigid

- Thread Type

- NA for flanged; Screwed BSP/NPT on request

- Connection Type

- Flanged End

- Temperature Range

- -10C to 220C

- Coating Type

- Epoxy Powder Coated

- Product Type

- Y Type Strainer

- Material

- Carbon Steel

- Connection

- Flanged

- Shape

- Y-shape

- Standard

- AISI

- Surface Treatment

- Epoxy Coated

- Outer Diameter

- Varies with size (e.g., 110 mm for 2 NB)

- Section Shape

- Round

- Length

- Varies with size (e.g., 205 mm for 2 NB)

- Thickness

- 6 mm (average)

- Color

- Blue

- Warranty

- 12 months

- Usage

- Liquid, steam, and gas line filtration

- Rated Pressure

- PN16 / Class 150

- Material Grade

- ASTM A216 Gr.WCB

- Application

- Pipeline debris removal

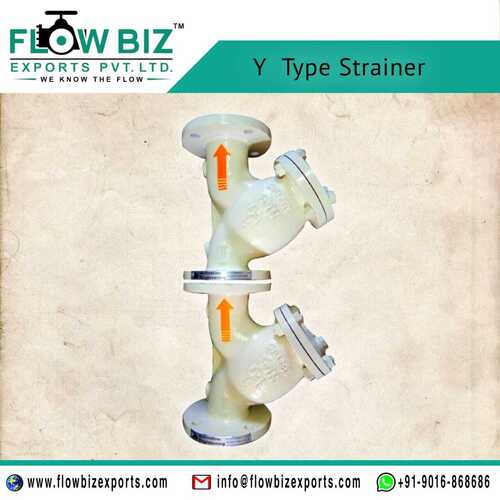

- Flow Direction

- Indicated by an arrow cast on body

- Screen Material

- Stainless Steel 304/316 mesh

- Blow-Off Connection

- Provided as standard

- End Connection Specification

- Drilled to ANSI B16.5 / DIN PN16

- Corrosion Resistance

- High due to epoxy coating

- Inspection & Certification

- Hydro tested at 1.5 times rating

- Operating Media

- Steam, Water, Oil, Air, Gases

- Mesh Size

- 40 to 60 mesh

- Installation Position

- Horizontal/Vertical (with flow downwards)

- Maintenance

- Easy removable cap for screen access

SPIRAX Marshall Y type Strainer Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 100 Per Week

- Delivery Time

- 1 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Standard

- Main Domestic Market

- All India

About SPIRAX Marshall Y type Strainer

SPIRAX Marshall FIG. 32 Strainers are available in Cast Iron, Cast Steel with stainless steel screen having 0.8 mm dia perforation as standard.

Available Sizes and Pipe Connections:

C.I. Fig. 32 Strainer - NB 40, 50, 80, 100, 150 & 200.

C.S. Fig. 32 Strainer - NB 40,50, 80, 100, 150, 200,250,300

Note: 1) For flanged strainers available in specific sizes/types of the strainer, please refer to tables 1 and 2.2)

Also available with IBR certificate on request.

Reliable Debris Removal for Pipelines

Engineered to efficiently capture and remove pipeline debris, the SPIRAX Marshall Y Type Strainer safeguards your system from clogging and damage. The indicated flow direction arrow and precise mesh screen optimize filtration for steam, water, oil, and gases.

Durable Construction and Corrosion Resistance

Built with high-grade carbon steel and epoxy powder coating, this strainer provides excellent corrosion resistance in demanding environments. The stainless steel mesh prevents material degradation, ensuring long-term reliability and maintenance ease.

Flexible Installation and Maintenance

The Y Type Strainer can be installed in either horizontal or vertical (downward flow) positions. Regular maintenance is simplified by an easy-to-remove cap that allows quick access to the screen, while the blow-off connection helps in hassle-free cleaning.

FAQs of SPIRAX Marshall Y type Strainer:

Q: How is the SPIRAX Marshall Y Type Strainer installed for optimal performance?

A: The strainer can be installed horizontally or vertically, provided the flow direction matches the cast arrow on the body and, for vertical installation, the flow should point downward. This ensures efficient debris capture and prevents blockages.Q: What types of media can be filtered using this Y type strainer?

A: This strainer is suitable for steam, water, oil, air, and gas lines, making it ideal for a wide range of industrial applications requiring debris removal from pipelines.Q: When is maintenance required, and how is the screen accessed?

A: Periodic inspection is recommended to ensure proper filtration. Maintenance is facilitated by an easy removable cap, providing straightforward access to the stainless steel mesh screen for cleaning or replacement.Q: Where should the SPIRAX Marshall Y Type Strainer be used?

A: It is designed for use in pipeline systems requiring reliable filtration, such as industrial, utility, or process lines. Its compatibility ranges from 15mm to 300mm NB diameters, allowing flexibility across varied installations.Q: What certification and quality assurance processes does the strainer undergo?

A: Each unit is hydro tested at 1.5 times its rated pressure, ensuring robust performance. Inspection and certification comply with industry standards, including AISI and ASTM specifications.Q: What benefits does the epoxy powder coating provide to the strainer?

A: The epoxy powder coating significantly enhances corrosion resistance, prolonging the service life of the strainer even under harsh operating conditions.Q: What are the advantages of the blow-off connection feature?

A: The standard blow-off connection allows for quick cleaning of the strainer without removal from the line, minimizing process downtime and maintaining optimal filtration efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Y Type Strainer Category

MS Fabricated Y Type Strainer

Price 5000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Color : As per request

Section Shape : Other

Material : Carbon Steel

Warranty : Yes

CI Y Type Strainer

Price 1000 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Section Shape : Round

Material : Iron

Carbon Steel Y Type Strainer

Price 1000 INR / Unit

Minimum Order Quantity : 1 Unit

Color : White

Section Shape : Round

Material : Carbon Steel

Warranty : Yes

Y Type Strainer

Price 2200 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Blue

Section Shape : Round

Material : Mild Steel

Warranty : Yes

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS