PTFE Lined Valve Manufacturer in Amreli

Price 5000 INR/ Unit

PTFE Lined Valve Manufacturer in Amreli Specification

- Control System

- Manual / Automated

- Valve Type

- PTFE Lined Valve

- Features

- Corrosion Resistant, Maintenance Free, Leak Proof

- Connection Type

- Flanged / Screwed / Wafer

- Material

- Ductile Iron / Carbon Steel / Stainless Steel

- Valve Size

- 1/2 to 12

- Voltage

- 24V / 110V / 220V (For Actuators)

- Sealing

- PTFE Lined

- Structure

- Two Piece / Three Piece Body

- Application

- Chemical, Pharmaceutical, Petrochemical Industries

- Type

- Ball Valve, Butterfly Valve, Plug Valve, Check Valve

- Power

- Manual / Pneumatic / Electric Actuation

- Pressure

- PN10 / PN16 / Class 150

- Media

- Acids, Alkalis, Solvents

- Port Size

- DN15 to DN300

- Temperature

- -29C to +200C

- Disc

- PTFE Lined / Stainless Steel

- Pin

- Stainless Steel

- Gasket

- PTFE / TFM / Gylon

- Operation

- Quarter Turn

- Handle Material

- Stainless Steel / Ductile Iron

- Inspection

- Hydrostatic & Pneumatic Tested

- Lining Thickness

- 3 mm Minimum

- End Connection

- ANSI B16.5 / DIN / JIS Standards

- Body Coating

- Epoxy Painted

- Design Standard

- ASME B16.34 / DIN

About PTFE Lined Valve Manufacturer in Amreli

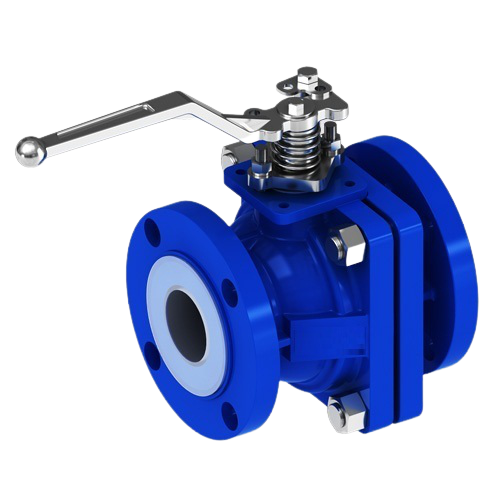

FlowBiz Exports brand PTFE Lined Ball Valves is a full port, two-piece split body design, bolted body construction with an integral ball and stem unit. Other features are DIN face-to-face, replaceable PTFE seat, bubble-tight shut-off, glandless design, maintenance-free, and full-flow efficiency.

A PTFE-lined ball valve is a type of ball valve that has a PTFE coating. The PTFE is a synthetic material known as polytetrafluoroethylene. The material prevents the core material from corroding under corrosive media. The ball valves come in different types as well.

Comprehensive Valve Engineering

Our PTFE lined valves are engineered to meet both ASME and DIN standards, ensuring robust performance and superior corrosion resistance. By utilizing advanced materials-like ductile iron or stainless steel with an epoxy-coated body and a seamless 3 mm minimum PTFE lining-these valves provide reliable service life in challenging environments. Quality inspection through hydrostatic and pneumatic tests guarantees impeccable durability and safety for critical applications.

Versatile Applications & Configurations

With a wide spectrum of valve types-including ball, butterfly, plug, and check valves-our solutions cater to chemical, pharmaceutical, and petrochemical sectors. From manual to pneumatic and electric actuation, and port sizes stretching from 1/2'' to 12'' (DN15 to DN300), these valves are designed for versatility. Choose from flanged, screwed, or wafer connections and benefit from tight sealing, leak-proof operations, and compatibility with aggressive media.

Advanced Control & Operation

Optimized for manual, pneumatic, or electric actuation, these PTFE lined valves offer quarter-turn operation and precision control for demanding systems. Their maintenance-free design, available with stainless steel or ductile iron handles and pins, reduces operational downtime. Automated models can be supplied with actuators suited for 24V, 110V, or 220V, providing flexible integration into modern control architectures.

FAQ's of PTFE Lined Valve Manufacturer in Amreli:

Q: How are PTFE lined valves manufactured to ensure chemical resistance and durability?

A: Our PTFE lined valves are fabricated with a robust base material-such as ductile iron, carbon steel, or stainless steel-and internally lined with a minimum 3 mm PTFE layer. This lining is resistant to most acids, alkalis, and solvents, ensuring long-term corrosion resistance. Each valve body is epoxy painted for additional protection, and all units undergo rigorous hydrostatic and pneumatic testing to guarantee their strength and leak-tightness.Q: What industries and media are PTFE lined valves suitable for?

A: These valves are ideal for chemical, pharmaceutical, and petrochemical industries. Their corrosion-resistant PTFE lining allows them to be used with highly corrosive fluids including acids, alkalis, and various solvents. The design also ensures suitability for applications where leakage and contamination cannot be tolerated.Q: When should you select a PTFE lined valve over a conventional valve?

A: PTFE lined valves are the preferred choice when handling aggressive or corrosive media that could rapidly degrade standard valve materials. Their superior chemical resistance and leak-proof performance make them essential in processes involving hazardous or reactive chemicals, especially where maintenance access is limited or downtime must be minimized.Q: Where are these PTFE lined valves typically installed within a process system?

A: These valves are commonly utilized at strategic points-such as isolation, control, and check locations-within pipelines transporting corrosive or hazardous media. Thanks to their diverse end connections (flanged, screwed, wafer), they easily integrate into international piping systems adhering to ANSI, DIN, or JIS standards.Q: What is the inspection and quality assurance process for these valves?

A: Each valve undergoes comprehensive hydrostatic and pneumatic testing to verify pressure integrity and operational reliability. The manufacturing process also complies with ASME B16.34 and DIN standards, ensuring dimensional accuracy, durability, and strict adherence to international quality norms.Q: How do PTFE lined valves benefit end users in terms of maintenance and longevity?

A: The non-stick, corrosion-resistant PTFE lining significantly minimizes wear and product buildup, leading to virtually maintenance-free operation. Their robust construction and advanced sealing technology ensure a long service life, reducing costs related to shutdowns, replacements, and unexpected leaks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in PTFE Lined Valve Category

PTFE Lined Plug Valve Manufacturer in Jamnagar

Price 700 INR / Unit

Minimum Order Quantity : 1 Number

Media : Other, Corrosive Fluids, Chemical, Water, Gas

Disc : Stainless Steel or Ductile Iron

Port Size : 15mm 300mm

Type : PTFE Lined Plug Valve

PTFE Lined Plug Valve Manufacturer in Surat

Price 1400 INR / Unit

Minimum Order Quantity : 1 Number

Media : Other, Liquids, Gases, Slurries, Acids

Disc : PTFE Lined Plug

Port Size : Full Bore

Type : PTFE Lined

PTFE Lined Butterfly Valve Manufacturer in Ahmedabad

Price 2000 INR / Unit

Minimum Order Quantity : 1 Unit

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS