PTFE Lined Butterfly Valve Manufacturer in Vadodara

Price 2200 INR/ Unit

PTFE Lined Butterfly Valve Manufacturer in Vadodara Specification

- Valve Size

- 2 to 24 (DN50 to DN600)

- Valve Type

- PTFE Lined Butterfly Valve

- Connection Type

- Wafer / Lug Mounting

- Control System

- Manual Gear / Pneumatic / Electric Actuator options

- Material

- Body: Cast Iron / Ductile Iron; Lining: PTFE

- Features

- Corrosion-resistant, Maintenance-free, Low Torque Operation, Leak Proof

- Structure

- Wafer / Lug Type

- Sealing

- PTFE Lined with Bubble Tight Shutoff

- Voltage

- 220V / 415V (for actuator)

- Application

- Suitable for corrosive and aggressive chemicals in chemical, pharmaceutical, and petrochemical industries.

- Type

- Butterfly Valve

- Power

- Manual, Pneumatic, or Electric Actuation

- Pressure

- Class 150 / PN10 / PN16

- Media

- Corrosive Liquids, Acids, Alkalis

- Port Size

- DN 50 to DN 600

- Temperature

- -50C to +180C

- Disc

- Ductile Iron / Stainless Steel with PTFE Lining

- Pin

- Stainless Steel

- End Connection

- Wafer / Lug

- Testing Standard

- API 598

- Body Coating

- FBE / Epoxy Powder Coated for Enhanced Protection

- Face to Face

- As per ANSI, DIN, or BS Standards

- Operation

- Quarter Turn (90 Degree Operation)

- Working Pressure

- up to 16 Bar

- Gland Packing

- PTFE

- Mounting

- ISO 5211 Actuator Mounting Pad

- Design Standard

- API 609 / DIN EN 593

- Color Coating

- Epoxy Painted / RAL Shade as Required

- Shaft Material

- Stainless Steel AISI 410 / 304 / 316

About PTFE Lined Butterfly Valve Manufacturer in Vadodara

Key Features:

FlowBiz proposes the best-in-class range of our PTFE Seated Butterfly Valve for Corrosive Application.

We hold expertise in manufacturing and supplying a superior quality array of PTFE Seat Butterfly Valve. Our butterfly valves are fabricated by using premium quality raw material and advanced machinery in compliance with the set quality standards. Our these vales are also offered in various specifications to meet the client requirements. This array of PTFE Seat Butterfly Valve can be availed from us at reasonable prices.

Premium Protection and Endurance

Every PTFE lined butterfly valve is engineered for longevity and protection against corrosive media. The valve body features a durable FBE or epoxy powder coating, and internal PTFE lining ensures resistance to acids and alkalis. This advanced construction extends operational life and reduces maintenance frequency, making the valve a reliable choice for demanding industrial environments.

Compliance with International Standards

We manufacture our butterfly valves in accordance with ANSI, DIN, BS, API 609, and DIN EN 593 standards, ensuring global compatibility and quality assurance. Rigorous testing is conducted per API 598 standards for leak-proof performance. Customers can choose from a range of face-to-face dimension options and connection types to meet unique application requirements.

FAQ's of PTFE Lined Butterfly Valve Manufacturer in Vadodara:

Q: How are PTFE lined butterfly valves suitable for corrosive chemical applications?

A: PTFE lined butterfly valves deliver excellent resistance to corrosive liquids due to their chemical-resistant PTFE lining and epoxy-coated cast iron or ductile iron bodies. This makes them ideal for handling acids, alkalis, and other aggressive chemicals found in chemical, pharmaceutical, and petrochemical industries.Q: What international standards do your butterfly valves comply with?

A: Our valves comply with ANSI, DIN, BS, API 609, and DIN EN 593 design standards. Testing is conducted as per API 598, ensuring leak-proof and bubble-tight shutoff performance for demanding industrial conditions.Q: Where can PTFE lined butterfly valves be installed?

A: These valves are commonly installed in pipelines conveying corrosive liquids within chemical, pharmaceutical, and petrochemical plants. Their versatile wafer and lug mounting options, plus ISO 5211 actuator pads, simplify integration into new or existing systems.Q: What is the operational process for these butterfly valves?

A: The valves feature quarter-turn operation (90 degrees) for quick and reliable control. Manual gear, pneumatic, or electric actuators can be used, accommodating both automated and manual control systems in industrial settings.Q: What are the benefits of using PTFE lined butterfly valves over standard valves?

A: PTFE lined butterfly valves provide maintenance-free operation, low torque requirements, superior corrosion resistance, and leak-proof shutoff. These features enhance process safety and reduce the total cost of ownership over time.Q: What is the temperature and pressure range supported by these valves?

A: The valves operate efficiently across temperatures from -50C to +180C, and support working pressures up to 16 Bar, making them suitable for a wide range of demanding applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in PTFE Lined Valve Category

PTFE Lined Valves Manufacturer in Mumbai

Price 2500 INR / Unit

Minimum Order Quantity : 1 Number

Application : Fluid Flow Control

Temperature : 20C to 200C Celsius (oC)

Port Size : Standard Sizes Available

Disc : PTFE Lined

PTFE Lined Diaphragm Valve Manufacturer in Jamnagar

Price 800 INR / Unit

Minimum Order Quantity : 1 Number

Application : industrial

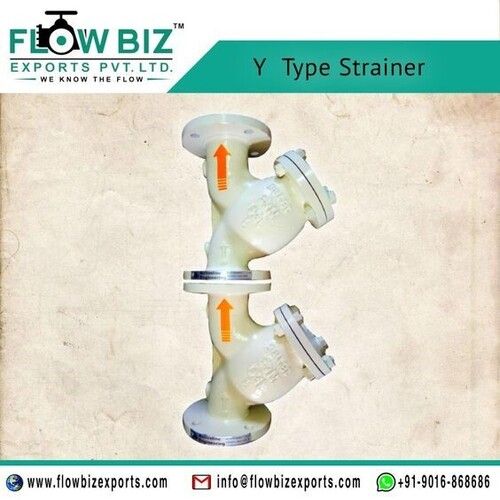

PTFE Lined Y Type Strainer Manufacturer in Gandhidham

Price 2500 INR / Unit

Minimum Order Quantity : 1 Number

Application : Process Industries likeChemical, Power, Refinery, Petrochemicals, Nuclear, Water

Temperature : Up to 200C Celsius (oC)

Port Size : Customized as per requirement

Disc : SS 304

PTFE Lined Valve Manufacturer in Kheda

Price 800 INR / Unit

Minimum Order Quantity : 1 Number

Application : Process Industries likeChemical, Power, Refinery, Petrochemicals, Nuclear, Water

Temperature : Up to 200C Celsius (oC)

Port Size : Customized as per requirement

Disc : SS 304

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS