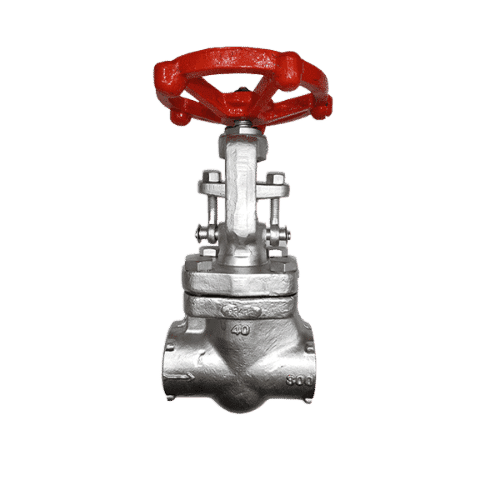

Globe Valves Manufacturer in Ahmedabad

Price 2500.00 INR/ Unit

Globe Valves Manufacturer in Ahmedabad Specification

- Connection

- Flange Type

- Usage

- Industrial

- Material

- Stainless Steel

- Power

- Manual

- Size

- 1/2" to 12"

- Media

- Water, Gas, Air

- Surface

- chrome Plating

- Shape

- Round

- Application

- Cooling Water System

- Color

- Silver

About Globe Valves Manufacturer in Ahmedabad

FlowBiz Exports has become a trusted name for Globe Valves mfg in India today. Our globe valves are excellent for stopping, starting, and regulating flow. We also thrive as one of the leading control valve manufacturers in India. Reliability and performance are the two fundamental concepts on which our butterfly valve mfg is based. We are the Ahmedabad valve manufacturer, selling and distributing a vast range of products to our national and global clients. ISI valves we supply meet the required quality standards. Our manufacturing units can produce valves that every industry demands and needs.

Special Features:

Rational structure, reliable sealing & sturdy

construction to ensure excellent performance.

Anti-friction bearings are provided in larger sizes and classes.

Sap globe Valves are heavy duty, outside screw & yoke type, bolted bonnet, rising stem with rising hand wheel.

Straight-through bore design assures streamlined, minimum turbulence, less erosion, lower pressure drop, & resistance to flow.

Deep stuffing box.

The seat rings are cylindrical bottom seated type having ample cross-section for strength and are provided with welded-in and threaded seat rings, which will be supplied on request an integral seat ring provided in SS valves.

Globe Valves are available in 150#, 300# & 600#.

Back Seat arrangement to provide isolation of Stuffing Box for On-Line serviceability

Excellent sealing against increased line pressure.

Premium Globe Valves for Industrial Use

Our stainless steel globe valves are engineered to deliver outstanding performance in demanding industrial environments. Featuring chrome plating and a sturdy round design, they offer remarkable resistance against corrosion and wear, making them ideal for cooling water systems. Available in sizes from 1/2" to 12" with flange connections, each valve guarantees a secure fit and minimal leakage, ensuring long-term reliability and efficiency.

Versatile Application & Quality Assurance

We cater to a diverse range of industrial requirements as a trusted exporter, manufacturer, supplier, and trader in India. Whether for water, gas, or air, our globe valves are built to excel. Each unit undergoes rigorous quality checks and meticulous chrome plating for enhanced durability. The manual operation facilitates easy maintenance and precise flow regulation across varied applications, ensuring optimal process performance.

FAQ's of Globe Valves Manufacturer in Ahmedabad:

Q: How are the globe valves from your Ahmedabad facility typically used in cooling water systems?

A: Our globe valves are integrated into cooling water systems to efficiently regulate the flow and pressure of water. Their precise design allows for accurate control, ensuring optimal cooling performance in industrial processes.Q: What are the main benefits of using stainless steel, chrome-plated globe valves for industrial applications?

A: Stainless steel with chrome plating provides exceptional resistance to corrosion, making the valves suitable for harsh industrial environments. This material combination extends the valve's lifespan and maintains reliable operation with water, gas, and air media.Q: When is a manual globe valve the preferred choice in an industrial setting?

A: Manual globe valves are best suited for applications where precise flow adjustment is needed and where full automation isn't essential. They allow operators to manually fine-tune the flow as per the process requirements.Q: Where can your globe valves be installed, and are they compatible with existing flange systems?

A: Our valves, produced in Ahmedabad, can be installed in any industrial setting requiring flange-type connections. Their design ensures compatibility with standard flange systems, facilitating straightforward integration into existing pipelines.Q: What is the process for ensuring quality and durability in your globe valves?

A: All globe valves undergo strict quality control, including material checks and chrome plating for enhanced surface protection. Each unit is thoroughly tested for pressure, leakage, and operational integrity before shipment.Q: How does the valve's round shape and flange connection benefit industrial installations?

A: The round shape enables uniform flow distribution, reducing turbulence and wear inside the valve. Flange connections ensure a robust, leak-proof joint, making maintenance and replacement more efficient in industrial setups.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Globe Valve Category

Needle Valve

Price 6000 INR / Unit

Minimum Order Quantity : 1 Number

Color : Silver

Surface : Other , Polished

Media : Other, Gas/Liquid

Angle Type Globe Valve

Price 6500 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Blue

Surface : Painted

Usage : Industrial

Media : Gas

Angle Type Globe Valves Manufacturer in Mumbai

Price 4000.00 INR / Unit

Minimum Order Quantity : 1 Number

Color : Silver

Surface : chrome Plating

Usage : Industrial

Media : Other, Water, Oil, Gas

Forged Steel Globe Valve Manufacturer in Kheda

Price 900 INR / Unit

Minimum Order Quantity : 1 Number

Color : Red & Silver

Surface : Powder Coated

Usage : Construction

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free