Four Way Ball Valve 2

Price 3000 INR/ Unit

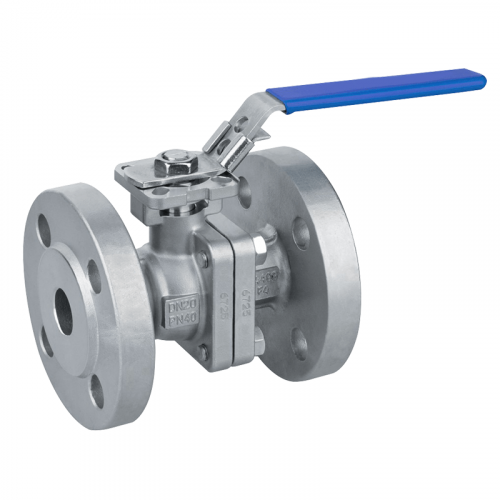

Four Way Ball Valve 2 Specification

- Pressure

- PN16, PN25, PN40

- Channels

- Four Way

- Connection

- Flanged

- Structure

- Four Way Ball

- Caliber

- Full Bore

- Material

- Stainless Steel

- Power

- Manual

- Media

- Water, Oil, Gas, Chemical

- Temperature of Media

- -20C to 180C

- Port Size

- 1/2 to 4

- Flange

- ANSI/DIN/JIS Standard

- Finish

- Polished

- Application

- Industrial, Chemical Processing, Water Treatment

About Four Way Ball Valve 2

FlowBiz Exports Pvt Ltd is a High Quality 4 way ball valve Manufacturer in Mumbai, Maharashtra, India. We are a leading manufacturer of 4 way ball valve in Mumbai and nearby areas.

4 Way Ball Valves are offered with L-L port or Double L Port and are manufactured with screwed ends. These valves are used when two right-angle diversions have to be done using one single valve. These valves will have two inlets and two outlets at any given time.

Advantages:

Multiple no of valves can be replaced by few no of valves.

Reduced Labor & Maintenance cost

Space saving

Flow diversion or Mixing can be more precise.

Features:

High Performance Ball Valve

Longer Life

Positive Shut off

Quick in Action

No Lubrication

Compact Design

Low Pressure Drop

Simplicity

Product Details:

Size - " to 2" (DN15 to DN50)

Class - 150#, 300#

Material - WCB, CF8M (SS316), CF8(SS304), Duplex SS, Inconel, Hastelloy

Port - Full Port

End connection - Screwed End (BSP / NPT)

Engineered for Reliability and Versatility

The Four Way Ball Valve 2 stands out due to its multi-directional flow capabilities and robust construction. Designed with a three-piece stainless steel body and full bore caliber, it manages a wide spectrum of media, including water, oil, gas, and chemicals. Its versatility is enhanced by flanged connections and the ability to mount on both panels and pipes. The polished finish adds corrosion resistance, making it suitable for harsh environments.

Superior Sealing and Easy Operation

With PTFE seats and seals, the valve ensures chemical compatibility and offers Class VI bubble-tight leakage protection for critical applications. It features a simple handle lever for quarter-turn manual operation, facilitating rapid and precise control. Maintenance is minimal thanks to the user-friendly design, supporting seamless operation in continuous industrial and chemical processing systems.

FAQs of Four Way Ball Valve 2:

Q: How does the Four Way Ball Valve 2 manage multi-directional flow?

A: This valve utilizes a full bore, four-channel internal structure, allowing for the controlled redirection of media in multiple directions. The quarter-turn handle lever enables users to quickly switch flow paths, making it ideal for complex piping systems requiring versatile flow control.Q: What materials are used in the construction of this valve?

A: The primary materials are stainless steel (SS 304 or SS 316) for the body and stem, and PTFE for the seats and seals. This combination ensures high strength, corrosion resistance, and compatibility with a wide array of industrial media including chemicals, oils, water, and gases.Q: When is this valve best suited for application?

A: The Four Way Ball Valve 2 is ideal for use in industrial, chemical processing, and water treatment facilities, especially where frequent redirection of flow is required, tight sealing is critical, and durability at high temperatures (up to 180C) and pressures (up to PN40) is needed.Q: Where can the valve be installed?

A: Thanks to its versatile mounting options, the valve can be installed on both panels and pipes. Its flanged ends comply with ANSI, DIN, and JIS international standards, making it adaptable for new installations or retrofits across various industries.Q: What is the maintenance process for this valve?

A: The three-piece construction allows for quick disassembly, making inspection, cleaning, or seat/seal replacement straightforward. Due to its robust materials and PTFE sealing, it requires minimal ongoing maintenance and provides easy cleanability.Q: How does the valve ensure leak-tight performance?

A: Equipped with PTFE seats and seals, the valve offers Class VI bubble-tight leakage performance, the highest industry standard for sealing. This feature is particularly beneficial in applications where any leakage could result in safety hazards or product loss.Q: What are the advantages of using the Four Way Ball Valve 2?

A: Key benefits include low maintenance, ease of cleaning, robust performance under challenging conditions, compatibility with various media, and compliance with international standards. Its versatility and reliability increase efficiency and process safety in complex flow networks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Ball Valve Category

High Pressure Ball Valve Manufacturer in Jamnagar

Price 800 INR / Unit

Minimum Order Quantity : 1 Number

Size : All size

Color : Silver

Material : Stainless Steel

Media : Other, Water, Oil, Gas

Single Piece Design Ball Valve

Price 1700 INR / Unit

Minimum Order Quantity : 1 Unit

Size : Different Available

Color : Silver, Black

Material : Stainless Steel

Media : Gas

Single Piece Ball Valve Manufacturer in Gandhinagar

Price 500 INR / Unit

Minimum Order Quantity : 1 Number

Size : Standard Sizes

Color : Silver

Material : Stainless Steel

Media : Water

Reduced Bore Trunnion Ball Valve

Price 3380 INR / Unit

Minimum Order Quantity : 10 Units

Size : Different Available

Color : Silver

Material : Brass

Media : Water

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free