Forged Steel Ball Valve Manufacturer in Surat

Price 1100 INR/ Unit

Forged Steel Ball Valve Manufacturer in Surat Specification

- Connection

- Socket Weld, Screwed, Flanged

- Channels

- Two Way

- Structure

- Ball Valve

- Pressure

- 150 to 800 Class

- Caliber

- Full Bore

- Material

- Forged Steel

- Power

- Manual

- Media

- Water, Oil, Gas, Steam

- Temperature of Media

- -20C to 200C

- Port Size

- 1/2 Inch to 4 Inch

- Flange

- ANSI, DIN, IS

- Finish

- Black Painted / Natural

- Application

- Industrial, Petrochemical, Refineries, Power Plants

About Forged Steel Ball Valve Manufacturer in Surat

Product Overview

Key Features

Focused on qualitative products and consumer satisfaction with our top-grade professionals' support, FlowBiz Exports manufactures and exports a wide gamut of forged steel ball valves from Surat, Gujarat, India.

Applications:

Oil Refineries

Chemical & Solvent Industries

Petrochemical Industries

Process Industries

Fertilizers

Gas Industries

Water Line Process

Steam Line

Power Plants and standard utilities

Precision Engineering for Demanding Applications

Our forged steel ball valves are engineered to provide dependable isolation in critical industrial processes. Featuring full bore design, manual lever operation, and a choice of PTFE or graphite seals, these valves ensure minimal leakage and long service life. With high corrosion resistance and fire-safe options, they are ideal for water, oil, gas, and steam across industries including refineries, petrochemicals, and power plants.

Comprehensive Testing & International Standards

Each valve is meticulously tested to API 598 standards to guarantee pressure and leakage integrity. Designed under API 6D and BS 5351, our products meet stringent global quality benchmarks. Multiple end connections-screwed (BSP/NPT), socket weld, flanged-offer installation versatility, and flange standards conform to ANSI, DIN, and IS for worldwide compatibility.

Versatility and Application Benefits

Suitable for media temperatures from -20C to 200C and pressures up to 800 class, our forged steel ball valves accommodate a range of port sizes from 1/2 inch to 4 inch. Their robust construction and full bore structure support smooth flow with reduced pressure drops, benefiting operational efficiency in demanding environments.

FAQ's of Forged Steel Ball Valve Manufacturer in Surat:

Q: How are forged steel ball valves manufactured and tested for quality assurance?

A: Forged steel ball valves are crafted from high-grade forged steel and assembled with PTFE or graphite seals for dependable performance. They undergo rigorous testing according to API 598 standards, ensuring robust pressure containment and minimal leakage before leaving our Surat facility.Q: What applications are best suited for these forged steel ball valves?

A: Our ball valves are ideal for industrial, petrochemical, refinery, and power plant applications. They handle a wide range of media, including water, oil, gas, and steam, making them versatile for high-pressure and high-temperature environments.Q: When should I choose a fire-safe design for my ball valve installation?

A: A fire-safe design is recommended when your application involves flammable media or operates in environments where fire risk is present. Our fire-safe ball valves offer enhanced safety by preventing leakage in the event of fire, safeguarding plant operations.Q: Where can your valves be installed in piping systems?

A: Our forged steel ball valves are designed for flexible installation, suitable for screwing (BSP/NPT), socket welding, or flanging (ANSI, DIN, IS) in a variety of pipelines, ensuring adaptability for both new constructions and retrofits.Q: What is the process of selecting the right end connection for a ball valve?

A: Determine your system's compatibility; use screwed ends for easy installation and removal, socket weld for permanent joints, or flanged ends when requiring easier maintenance. We offer all options to ensure seamless integration with your piping layout.Q: How does the choice of seal material (PTFE or graphite) benefit different applications?

A: PTFE seals provide excellent chemical resistance and low friction, ideal for general and corrosive service. Graphite seals perform well in higher temperature and pressure scenarios, offering enhanced durability in demanding applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Ball Valve Category

Trunnion Mounted Ball Valve Manufacturer in Surat

Price 2500 INR / Unit

Minimum Order Quantity : 1 Number

Media : Other, Water, Oil, Gas

Material : Other, Carbon Steel, Stainless Steel, Alloy Steel

Application : Petrochemical, Oil & Gas, Power, Water Treatment

Finish : Painted / Coated

Metal Seated Ball Valve Manufacturer in Vapi

Price 4300 INR / Unit

Minimum Order Quantity : 1 Number

Media : Other, Water, Oil, Gas, Steam

Material : Stainless Steel

Application : Industrial, Chemical, Petroleum, Paper, Food Industries

Finish : Polished

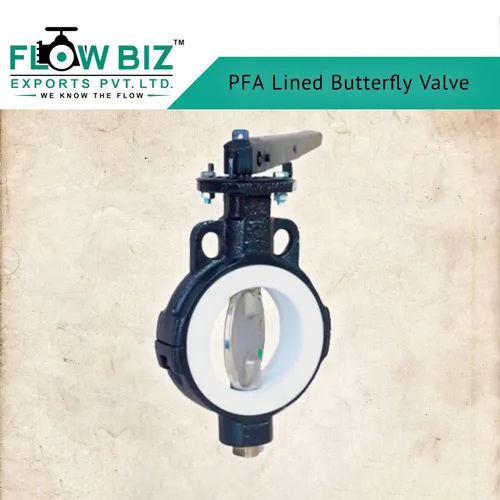

PFA Lined Butterfly Valve

Price 7800 INR / Unit

Minimum Order Quantity : 1 Unit

Media : Water

Material : Brass

Application : Industrial

Finish : Painted

Three Way Full Port Ball Valve

Price 890 INR / Unit

Minimum Order Quantity : 1 Unit

Media : Water

Material : Brass

Application : Industrial

Finish : Polished

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free