Duplex Strainers Manufacturer in Vadodara

Price 1600 INR/ Unit

Duplex Strainers Manufacturer in Vadodara Specification

- Application

- Process Industries like-Chemical, Power, Refinery, Petrochemicals, Nuclear, Water

- Type

- Manual

- Media

- Water

- Port Size

- Customized as per requirement

- Temperature

- Up to 200C Celsius (oC)

- Disc

- SS 304

About Duplex Strainers Manufacturer in Vadodara

A duplex strainer or twin basket strainer is a kind of filter built into a fuel, oil, or water piping system, and it is used to clear large particles of dirt and debris.

The duplex strainer system usually consists of two separate strainer basket housings. The system also contains a valve handle between the two baskets to divert the liquid flow to one filter while the other is being cleaned. The valve will work automatically on some filters, and the strainer will perform a self-cleaning function.

Features:

- Optimum finish

- Best quality

Engineered for Versatile Industrial Use

Our Duplex Strainers are specifically designed for demanding industrial environments. They are ideal for applications that require uninterrupted filtration, thanks to their dual-chamber design which allows cleaning without process shutdown. Made of SS 304 and able to handle water at temperatures up to 200C, these strainers are suited for critical operations in chemical, power, refinery, nuclear, and petrochemical plants.

Customizable Solutions and Superior Performance

Every process has unique needs, which is why we offer customized port sizes to fit your system specifications precisely. Whether you are upgrading an existing setup or designing a new one, our team provides tailored guidance and robust manufacturing to ensure optimal flow rates and filtration efficiency. Our commitment to quality and customer satisfaction distinguishes us as a premier supplier in India and abroad.

FAQ's of Duplex Strainers Manufacturer in Vadodara:

Q: How do Duplex Strainers function in process industries?

A: Duplex Strainers operate by directing water through two parallel chambers fitted with SS 304 disc filters. While one chamber filters, the other can be cleaned or serviced, allowing for continuous operation in applications such as chemical processing, power generation, and petrochemicals.Q: What benefits do SS 304 discs offer in these strainers?

A: SS 304 discs provide excellent corrosion resistance, durability, and strength, making them well-suited for water filtration at elevated temperatures up to 200C. This ensures long service life and reduces maintenance frequency, even in aggressive industrial environments.Q: When should a manual Duplex Strainer be cleaned or switched?

A: Manual Duplex Strainers should be cleaned or switched when the differential pressure gauge indicates a rise due to clogging, or as part of routine maintenance schedules established based on the specific process and contamination levels in the media.Q: Where are your Duplex Strainers typically installed?

A: Our Duplex Strainers are installed at critical filtration points across chemical plants, power stations, refineries, nuclear facilities, and water treatment plants throughout India and for export globally. They are integrated upstream of sensitive equipment to protect operations from particulate contamination.Q: What is the process for customizing the port size?

A: We offer port size customization based on client specifications. After assessing your flow requirements and existing piping dimensions, our engineering team designs and fabricates the strainers to ensure seamless integration into your process system.Q: How are your Duplex Strainers used in refinery and power industry applications?

A: In refineries and power industries, Duplex Strainers are used to filter process water, cooling water, and various liquid streams. Their uninterrupted operation guards crucial equipment against blockages and wear, contributing to enhanced reliability and reduced downtime.Q: What is the main advantage of using Duplex Strainers for water filtration at high temperatures?

A: The principal advantage is their capability to filter water at temperatures up to 200C without pausing process flows, maintaining operational continuity and protecting valuable machinery even under demanding thermal stress.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in strainer Category

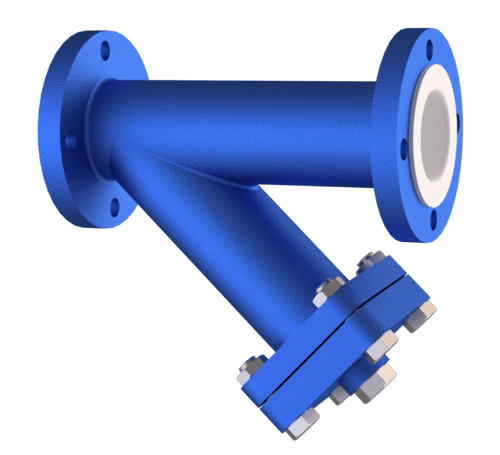

PTFE Lined Y Strainer Manufacturer in Kheda

Price 1500 INR / Unit

Minimum Order Quantity : 1 Number

Application : Chemical Industry, Pharmaceuticals, Water Treatment, Petrochemicals

Material : CS/SS with PTFE/FEP/PFA Lining

Media : Other, Liquids, Gases, Corrosive Fluids

Features : Corrosion Resistant, Low Pressure Drop, Easy Maintenance, High Chemical Compatibility

Conical Type Strainer Manufacturer in India

Price 4000 INR / Unit

Minimum Order Quantity : 1 Number

Application : Pipeline filtration in oil, gas, chemical, and water treatment industries

Material : Carbon Steel, Stainless Steel (SS304, SS316), Alloy Steel, Brass (as required)

Media : Other, Liquids and gases

Features : Easy installation, Low maintenance, Durable construction, High filtration efficiency

Duplex Type Strainer Manufacturer in Mumbai

Price 2000 INR / Unit

Minimum Order Quantity : 1 Number

Material : MS

Features : Good Quality

Basket Type Strainer Manufacturer in Gandhinagar

Price 800 INR / Unit

Minimum Order Quantity : 1 Number

Material : MS

Features : Good Quality

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free