Double Flange Damper Valve (Fabricated)

Price 6000 INR/ Unit

Double Flange Damper Valve (Fabricated) Specification

- Connection

- Double Flanged

- Valve Type

- Double Flange Damper Valve (Fabricated)

- Material

- Mild Steel / Stainless Steel

- Power Source

- Manual / Electric Actuator / Pneumatic Actuator

- Pressure

- Up to 6 Bar

- Media

- Air, Gases, Light Dust

- Working Temperature

- -10C to +180C

- Port Size

- 100mm to 1600mm

- Shape

- Round / Rectangular

- Operation

- Quarter Turn

- Mounting

- Between Flanges / Flanged Ends

- Body Construction

- Fabricated

- End Connection Standard

- Drilled to ANSI / BS / DIN

- Blade Type

- Single Flat Blade

- Seal Type

- Rubber / Metal to Metal

- Face to Face Dimension

- As per IS/ANSI Standard

- Size Range

- Custom sizes available

- Surface Finish

- Epoxy Painted

- Design Standard

- Custom / IS / ANSI

- Leakage

- Low Leakage Design

- Application

- HVAC / Pollution Control / Industrial Ventilation

About Double Flange Damper Valve (Fabricated)

Double Flange Damper Valve (Fabricated)

Damper Butterfly Valves are suitable for applications where the leakage is unimportant. Damper Butterfly Valve is also the best option for isolating damper for flue gas scrubbers.

FlowBiz Damper Butterfly Valves are lightweight, easy, rapidly actuated, and often inexpensive. The drive for a butterfly damper is also simple, requiring only 90 of motion.

Size Range: 8 inches to 80 inches (200mm to 2000mm)

PRESSURE/ TEMPERATURE:

WORKING RATING:5 KG/CM2

TEMPERATURE UP TO TO:1200 C

Precision Engineering for Industrial Demands

This valve is meticulously designed to meet the stringent requirements of industrial ventilation, pollution control, and HVAC systems. Its fabricated body, low-leakage construction, and adaptable sealing options deliver reliable performance in challenging environments. Operators benefit from easy installation and versatile mounting options, with sizes tailored to specific project needs.

Versatile Operation and Control

With a choice of manual, electric, or pneumatic actuation, the Double Flange Damper Valve can be seamlessly integrated into a variety of control systems. The quarter-turn operation delivers swift shut-off and regulation, ensuring process stability and responsive airflow management in all applications.

FAQ's of Double Flange Damper Valve (Fabricated):

Q: How does the quarter-turn operation benefit Double Flange Damper Valve users?

A: The quarter-turn mechanism allows for rapid opening or closing of the valve, enabling efficient control of media flow in HVAC and industrial systems. It simplifies operation and helps maintain desirable system parameters.Q: What types of media can this damper valve handle?

A: The Double Flange Damper Valve is suitable for air, gases, and light dust, making it ideal for use in ventilation, HVAC, and pollution control applications.Q: When should I choose rubber versus metal-to-metal sealing for my damper valve?

A: Choose a rubber seal for enhanced leak tightness in low-pressure scenarios, and opt for metal-to-metal seals when dealing with higher temperatures or abrasive media that require robust, durable sealing surfaces.Q: Where are double flange damper valves commonly installed?

A: These valves are typically mounted between flanges or at flanged ends in ducts and pipelines across industrial, commercial, and environmental projects throughout India and internationally.Q: What is the process for customizing the valve's size and configuration?

A: Customers can specify their required dimensions, shape (round/rectangular), material, and end connection standard (ANSI, BS, DIN). The manufacturer will fabricate the valve according to these specifications to ensure compatibility and performance.Q: How does low leakage design improve system performance?

A: Low leakage minimizes energy loss and prevents undesired media escape, improving system efficiency and reducing overall environmental impact.Q: What are the main benefits of using this valve for HVAC and pollution control?

A: The valve's adaptability to various media and mounting standards, robust construction, low leakage, and custom sizing make it an effective solution for ensuring efficient airflow, reduced maintenance, and reliable sealing in demanding industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Butterfly Valve Category

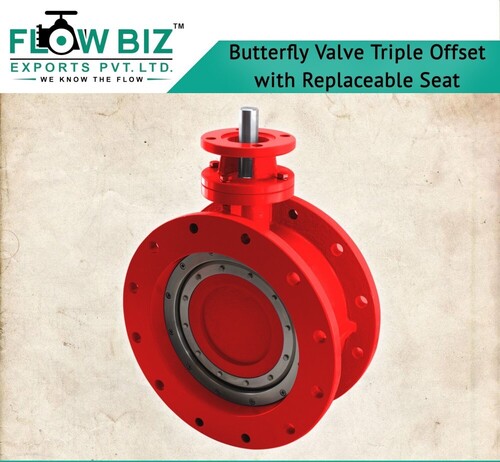

Triple Offset Butterfly Valve Manufacturer in Surat

Price 4000 INR / Unit

Minimum Order Quantity : 1 Unit

Shape : Round

Material : Cast Iron

Media : Water

Metal Seat Butterfly Valve Manufacturer in Surat

Price 2400 INR / Unit

Minimum Order Quantity : 1 Number

Shape : Round

Material : Other, Metal (Stainless Steel)

Connection : Other, Flanged

Media : Other, Liquid/Gas

Damper Valve

Price 8000 INR / Unit

Minimum Order Quantity : 1 Number

Shape : Round

Material : Other, Mild Steel

Connection : Other, Flanged

Media : Other, Air

Spherical Disc Butterfly Valve

Price 6000 INR / Unit

Minimum Order Quantity : 1 Number

Shape : Round

Material : Other, Cast Iron / Stainless Steel / Ductile Iron

Connection : Other, Wafer / Lug / Flanged

Media : Other, Water, Gas, Oil, Air, Chemicals

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free