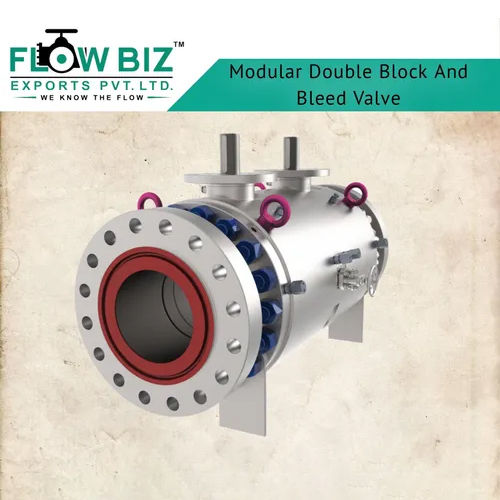

Double Block Bleed Plug Valve

Price 800 INR/ Unit

Double Block Bleed Plug Valve Specification

- Application

- Industrial

- Type

- Double Block Bleed Plug Valve

- Power

- Pneumatic

- Pressure

- High Pressure

- Product Type

- Double Block Bleed Plug Valve

- Color

- Blue

Double Block Bleed Plug Valve Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Week

- Delivery Time

- 5 Days

- Main Domestic Market

- All India

About Double Block Bleed Plug Valve

Double Block & Bleed Plug Valve

2 inches to 30 inches (50mm to 750mm) - 150 Class

Length: 2 inches to 24 inches (50mm to 600mm) - 300 Class

Length: 2 inches to 12 inches (50mm to 300mm) - 600 Class

Applications :

Blending Units

Product Isolation

Multi-Product Manifolds

Prover Loops

ards and customer specifications.

FlowBiz expanding plug valves are ideal for applications that require positiveshutoff, verifiable zero leakage and double block and bleed (DB&B) or doubleisolation and bleed (DIB) capability.

Range

Size 2 inch to 30 inch 50mm to 750mm 150 Class

Size 2 inch to 24 inch 50mm to 600mm 300 Class

Size 2 inch to 12 inch 50mm to 300mm 600 Class

Engineered for High-Pressure Industrial Needs

Our Double Block Bleed Plug Valve is meticulously designed to excel under high-pressure conditions commonly found in industrial settings. It ensures dual isolation and an essential bleed mechanism, providing superior safety and maintenance convenience during plant operations. The pneumatic power system equips users with easy and reliable control, even in the most challenging operational environments.

Trusted Solution Across Indian Industries

Sourced and manufactured by experienced Indian exporters and suppliers, this valve meets stringent quality and safety standards. Its widespread adoption across the country underscores its reliability and versatility. Our commitment ensures you receive a durable, long-lasting valve solution suitable for a broad range of industrial applications.

FAQ's of Double Block Bleed Plug Valve:

Q: How does a Double Block Bleed Plug Valve function in high-pressure applications?

A: The Double Block Bleed Plug Valve provides dual isolation by using two sealing seats and a central cavity that can be bled to release pressure. This is especially useful in high-pressure applications, offering enhanced safety during isolation or maintenance.Q: What are the primary industrial applications of this valve?

A: This valve is used in processes that require reliable isolation of pipeline sections for maintenance or repair. It is commonly found in oil and gas, petrochemical, and power generation facilities where high-pressure fluid handling is routine.Q: When should a Double Block Bleed Plug Valve be installed in a system?

A: Install this valve when dual isolation and positive pressure relief are paramount for safety or maintenance. It is typically used during plant commissioning, shutdowns, or any operation requiring secure blockage and depressurization.Q: Where are these valves typically supplied from in India?

A: We export, manufacture, supply, and trade these Double Block Bleed Plug Valves from India. Our network covers major industrial regions, ensuring timely delivery and support across the country.Q: What is the process for operating the pneumatic Double Block Bleed Plug Valve?

A: Operation is achieved pneumatically, allowing remote or automated control. The valve actuates with compressed air, ensuring smooth and rapid switching between open, closed, and bleed positions for efficient system management.Q: How is the valve maintained for long-term performance?

A: Regular inspection and periodic testing of the seals and pneumatic actuators are recommended. Bleed points should be checked for proper pressure release function, maintaining operational safety and valve integrity.Q: What are the key benefits of using this valve in industrial settings?

A: The valve's double block and bleed feature enhances operator safety and streamlines maintenance procedures. Its high-pressure capability and pneumatic operation ensure reliable, quick response, and reduced downtime in critical industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Double Block Bleed Valve Category

Double Block Bleed Valve Manufacturers in Jamnagar

Price 700 INR / Unit

Minimum Order Quantity : 1 Number

Power : Manual

Size : All size

Type : Double Block & Bleed

Product Type : Double Block Bleed Valve

Double Block And Bleed Ball Valve

Price 5400 INR / Unit

Minimum Order Quantity : 1 Unit

Power : Pneumatic

Size : Different Available

Type : Double Block And Bleed Valve

Product Type : Double Block And Bleed Valve

Audco Regular Pattern Plug Valve

Price 1200 INR / Unit

Minimum Order Quantity : 1 Unit

Power : Pneumatic

Size : Different Available

Type : Audco Regular Pattern Plug Valve

Product Type : Audco Regular Pattern Plug Valve

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free