Diaphragm Valve Manufacturers in Mumbai

Price 2400 INR/ Unit

Diaphragm Valve Manufacturers in Mumbai Specification

- Connection Type

- Flanged

- Features

- Corrosion resistance compact design

- Valve Type

- Manual diaphragm type

- Valve Size

- Standard valve sizes

- Material

- Cast iron with rubber lining

- Control System

- Manual

- Sealing

- Rubber diaphragm seal

- Application

- Industrial fluid control

- Voltage

- Not applicable (manual operation)

- Structure

- Diaphragm valve structure

- Type

- Diaphragm valve

- Power

- Not applicable (manual operation)

- Pressure

- Medium Pressure

- Media

- Liquid gas

- Port Size

- Standard sizes available

- Temperature

- Up to 80C

- Disc

- Diaphragm-based sealing

- Pin

- Stainless steel

About Diaphragm Valve Manufacturers in Mumbai

FlowBizValves is a High-PerformanceDiaphragm ValveManufacturer in Ahmedabad, Mumbai, India. Diaphragm solenoid valves include a rubber diaphragm that forces up and down within the valve's body, moving to open and close against a problematic seat. In simple terms, the primary objective of a diaphragm solenoid valve is to contain the flow of fluids and gases.

Diaphragm valves are particle valves that use a liner as parts of the valve body rather than a diaphragm. The diaphragm is a pressure-responsive element that is entirely flexible and makes the power necessary to open, close or maintain the operation of the valve. Diaphragm valves can take fluids, gaseous fluids, and semi-solid media.

Reliable Manual Operation for Industrial Applications

Our diaphragm valves are engineered for manual fluid control, requiring no external power or voltage. This simplifies maintenance and reduces operating costs, making them suitable for a wide range of industrial processes where precise media flow is essential.

Corrosion-Resistant Design for Longevity

Constructed with cast iron bodies and protected by a rubber lining, these valves offer excellent resistance against corrosive fluids and gases. The stainless steel pin enhances structural stability, ensuring longevity and sustained performance in harsh operating conditions.

Versatile Connection and Application

Featuring standard flanged connections, these diaphragm valves are easy to integrate into existing systems. Their compatibility with various industrial liquids and gases, as well as medium pressure operation, broadens their application across multiple sectors.

FAQ's of Diaphragm Valve Manufacturers in Mumbai:

Q: How does a manual diaphragm valve operate in industrial fluid control systems?

A: A manual diaphragm valve uses a hand-operated mechanism to control the internal rubber diaphragm, regulating the flow of liquids or gases through the system without needing electrical power or automation.Q: What benefits does the rubber diaphragm seal provide in these valves?

A: The rubber diaphragm seal ensures tight closure, preventing leaks, while its flexibility resists wear and corrosion, offering superior sealing performance and a longer service lifespan, especially in aggressive or corrosive media.Q: Where can these diaphragm valves be used within industrial applications?

A: These valves are ideal for process industries such as water treatment, chemical processing, food and beverage plants, and pharmaceutical manufacturing, where reliable flow control for liquids and gases is required.Q: What is the installation process for flanged diaphragm valves?

A: Installation involves aligning the valve's flanged ends with the corresponding pipeline flanges, inserting the appropriate gaskets, and securing the assembly with bolts to create a leak-proof connection.Q: When should a diaphragm valve be preferred over other valve types?

A: A diaphragm valve is preferred when precise throttling or complete leak-tight shutoff is needed, particularly with corrosive, viscous, or abrasive media that might damage conventional valve mechanisms.Q: What are the advantages of using cast iron with rubber lining for the valve body?

A: Cast iron ensures solid structural support, while the rubber lining provides chemical resistance and protects the valve from corrosion, making it suitable for a variety of aggressive industrial media.Q: What maintenance practices ensure continued performance of manual diaphragm valves?

A: Regularly inspect the diaphragm for signs of wear or degradation, check the valve for leaks and ensure all bolts and flanges remain properly tightened to maintain efficient and reliable valve operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Non Return Valve Category

Non Return Valve Manufacturer in Amreli

Price 2000 INR / Unit

Minimum Order Quantity : 1 Number

Application : Industrial, Water, Oil, Gas

Type : Non Return Valve (NRV)

Media : Other, Water, Oil, Gas

Non Return Valve Manufacturer in Anand

Price 2000 INR / Unit

Minimum Order Quantity : 1 Number

Application : Water, Oil, Gas

Type : Non Return Valve

Media : Other, Fluid, Air, Gas, Water

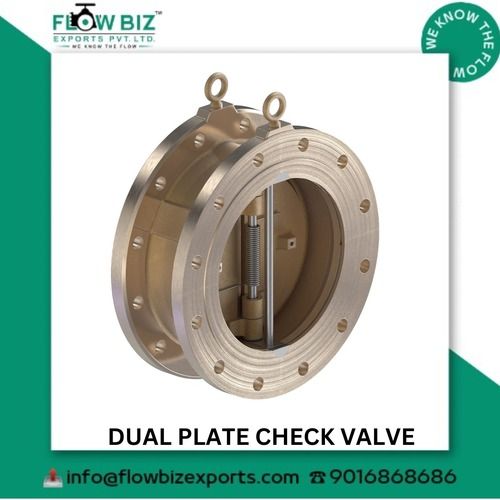

Dual Plate Check Valve

Price 500 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Blue

Application : Industrial

Type : Kirloskar Swing Type Foot Valve

Media : Gas

Audco L T Make Lift Type Non Return Valve

Price 497 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Black

Application : Industrial

Type : Audco L T Make Lift Type Non Return Valve

Media : Gas

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free