Basket Type Strainer Manufacturer in Jamnagar

Price 800 INR/ Unit

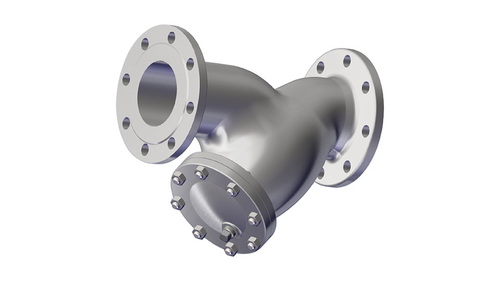

Basket Type Strainer Manufacturer in Jamnagar Specification

- Application

- industrial

- Usage

- Construction

- Size

- All size

- Media

- Water

- Color

- Green

Basket Type Strainer Manufacturer in Jamnagar Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 100 Per Week

- Delivery Time

- 7 Days

About Basket Type Strainer Manufacturer in Jamnagar

FlowBiz Advantages of Using Basket Strainers

Installing a basket strainer into a pipeline system ensures that equipment downstream is protected from unwanted and potentially damaging debris.

Choose a mesh size slightly smaller than the particles you wish to filter to ensure that any foreign particles are trapped in the basket. You will also want to consider other factors, like the temperature and pressure requirements and the type of liquid or gas passing through the basket strainer. Ensure your basket strainer is maintained by checking pressure periodically and scheduling regular cleanings. This small investment will have a lasting impact on downstream equipment.

Industrial Grade Filtration Solutions

Our basket type strainers are meticulously crafted to withstand the rigors of industrial environments. Their robust construction delivers exceptional durability and efficient filtration, making them essential for water treatment in construction and various other sectors.

Comprehensive Size Range

We offer basket type strainers in all standard and custom sizes. Whether your project demands compact units or large-scale filtration, our extensive range ensures you find the ideal fit for your application, enhancing both efficiency and reliability.

FAQ's of Basket Type Strainer Manufacturer in Jamnagar:

Q: How do basket type strainers work in industrial water applications?

A: Basket type strainers operate by allowing water to pass through a mesh or perforated basket, which traps and retains solid debris. This prevents unwanted particles from entering pipelines and equipment, effectively protecting your system from blockages and damage.Q: What is the manufacturing process for these basket type strainers?

A: We manufacture our basket type strainers using high-quality materials, precision engineering, and thorough quality checks. Each unit undergoes advanced fabrication and finishing processes, including a green protective coating, to ensure long-lasting performance and corrosion resistance.Q: When should a basket type strainer be used in construction or industrial settings?

A: Basket type strainers should be installed whenever solid particles in water could harm equipment, compromise processes, or reduce efficiency. Common scenarios include protecting pumps, valves, and heat exchangers during construction or ongoing industrial operations.Q: Where are your basket type strainers exported and supplied from Jamnagar?

A: As a leading manufacturer and exporter based in Jamnagar, India, we supply our basket type strainers nationally and internationally, serving clients in construction, water treatment, and diverse industrial sectors.Q: What are the major benefits of using your basket type strainers for water filtration?

A: Using our basket type strainers increases equipment lifespan, decreases maintenance downtime, and enhances system efficiency by reliably removing debris from water. The green finish also provides additional resistance to environmental factors.Q: How can I select the correct size and specification for my application?

A: Our team assists you in selecting the optimal strainer based on your flow rate, pipe size, debris load, and application requirements. With all sizes available, we ensure you receive a product tailored to your operational needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in strainer Category

T Type Strainer Manufacturer in Vadodara

Price 1700 INR / Unit

Minimum Order Quantity : 1 Number

Material : Carbon Steel, Stainless Steel 304/316, Alloy Steel

Features : Corrosion resistant, easy maintenance, robust design, high dirt holding capacity

Temperature : Up to 250°C

Strainer Valve Manufacturers in Gandhinagar

Price 800 INR / Unit

Minimum Order Quantity : 1 Number

Material : SS

Features : Good Quality

Product Type : Valve Strainers

Y Type Strainer Manufacturer in Rajkot

Price 800 INR / Unit

Minimum Order Quantity : 1 Number

Material : MS

Features : Good Quality

Product Type : Y Type Strainer

Pot Strainer Manufacturer in Surat

Price 2000 INR / Unit

Minimum Order Quantity : 1 Number

Material : MS

Features : Good Quality

Product Type : Pot Strainer

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free