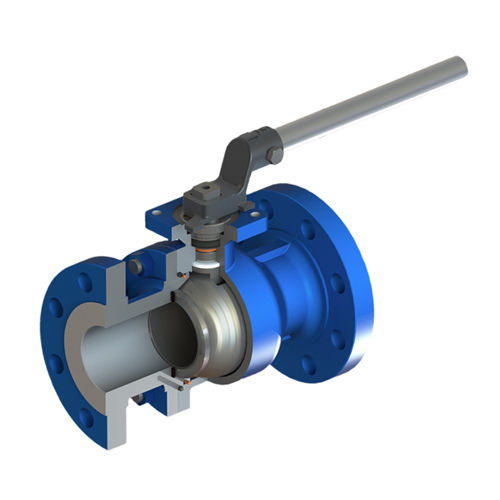

Ball Valve Manufacturers in Ahmedabad

Price 1500 INR/ Unit

Ball Valve Manufacturers in Ahmedabad Specification

- Material

- Stainless Steel

- Media

- Water

- Temperature of Media

- -40 DegreeF to 392 DegreeF Fahrenheit (oF)

- Flange

- Flanged End

- Finish

- Plain

- Application

- Air, Liquid , Gas

About Ball Valve Manufacturers in Ahmedabad

FlowBiz Exports is a leading ball valve manufacturer in Ahmedabad. Our ball valve mfg production unit has advanced technologies and the latest manufacturing methods. We hold all the latest testing capabilities; thus, our customers receive high-quality products from our valves mfg in Ahmedabad. Quality products at a competitive price are the trademark of our high-pressure valve mfg. Our production engineers can produce custom valves to suit our customers' business and application specifications. Therefore, we are the most demanded service of control valve manufacturers in India.

Special Features:

- Free floating ball design provides seat wear compensation and longer life.

- Provide fire safe design as per APO 607 / API 6FA / BS 6755-II with single point contact seat design.

- Blow out proof and Anti blow out stem construction.

- Micro-finished ball provides a positive seal.

- Straight through flow path for minimum pressure drop.

- Bi-directional flow.

- 90 (Quarter-turn) actuation.

- Wide selection of seat materials.

- Extended stem/extended bonnet design as per customers specific pipe line usage.

- Antistatic devices ensure electrical continuity between Body, ball & stem.

- Triple stem seal with accurate stem.

- Handle indicates flow direction.

- ISO 5211 top mounting pad for simplified gear / actuator in 150#, 300# & 600# as optional in only flanged end design.

- Variety of end connections.

Engineered for Wide Temperature Range

Our flanged end ball valves are specifically designed to function efficiently in extreme environments, withstanding temperatures from -40F up to 392F. This makes them an excellent choice for industries where thermal fluctuations are common, bringing reliable performance in demanding conditions.

Versatile Material Applications

Manufactured using high-grade stainless steel, these ball valves offer reliable corrosion resistance and longevity. Suitable for media including air, liquids, gas, and water, they support a wide array of industrial and utility requirements, ensuring compatibility and safety in various operational environments.

FAQ's of Ball Valve Manufacturers in Ahmedabad:

Q: How are flanged end ball valves from Ahmedabad beneficial for industrial applications?

A: Flanged end ball valves manufactured in Ahmedabad provide a robust sealing mechanism, corrosion resistance due to stainless steel construction, and reliable operation across broad temperature ranges. This ensures efficiency, minimizes leakage, and enhances safety in industrial settings.Q: What is the process for installing a flanged ball valve with a plain finish?

A: Installation involves aligning the flanged ends of the valve with the pipeline flanges, securing them with appropriate bolts, and ensuring proper gasket placement. The plain finish offers smooth integration and easy maintenance, resulting in efficient valve operation.Q: When should I choose a stainless steel ball valve for my application?

A: A stainless steel ball valve is ideal when the application demands durability, resistance to corrosion, and compatibility with various media such as air, water, gas, and liquids, especially within a temperature range of -40F to 392F.Q: Where can I find reputable exporters and suppliers of ball valves in India?

A: Ahmedabad is a well-known hub for ball valve manufacturers, exporters, suppliers, and traders in India. Reputable companies from this region offer products that meet international quality standards and can cater to domestic and global requirements.Q: What media can these ball valves handle, and are there any limitations?

A: These stainless steel ball valves are suitable for handling air, liquids, gas, and water. They are designed for versatility and safety, but suitability should always be confirmed based on specific pressure and chemical compatibility needs.Q: How does the temperature range affect the valve's performance?

A: The specified temperature range of -40F to 392F allows the valve to function reliably in both extremely cold and hot environments, ensuring flow control stability and sealing integrity even under fluctuating thermal conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Ball Valve Category

Metal Seated Ball Valve Manufacturer in Ahmedabad

Price 2000 INR / Unit

Minimum Order Quantity : 1 Number

Application : Chemical, Petrochemical, Power, Oil & Gas, Refinery, Pulp & Paper, Mining, Sugar, Steel Plants

Material : Other, Stainless Steel / Alloy Steel / Cast Iron / Carbon Steel (WCB, LCB, WC6, WC9, CF8, CF8M) / Duplex Steel

Temperature of Media : 29C to 425C

Media : Other, Water, Oil, Gas, Steam, Slurry, HighTemperature Fluids

PTFE Lined Ball Valve Manufacturer in India

Price 2000 INR / Unit

Minimum Order Quantity : 1 Number

Application : Chemical, Petrochemical, Pharmaceutical, Water Treatment

Material : Other, PTFE Lined (Body: Ductile Iron / Carbon Steel / Stainless Steel options available, Lining: PTFE)

Temperature of Media : 29C to +180C

Media : Other, Acids, Corrosive Liquids, Chemicals

Metal Seated Ball Valve Manufacturer in Jamnagar

Price 500 INR / Unit

Minimum Order Quantity : 1 Number

Application : Industrial

Material : Stainless Steel

3 way and 4 way Ball Valve Manufacturer in Vadodara

Price 2000 INR / Unit

Minimum Order Quantity : 1 Number

Application : Air, Liquid , Gas

Material : Stainless Steel

Temperature of Media : 40 DegreeF to 392 DegreeF Fahrenheit (oF)

Media : Water

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS