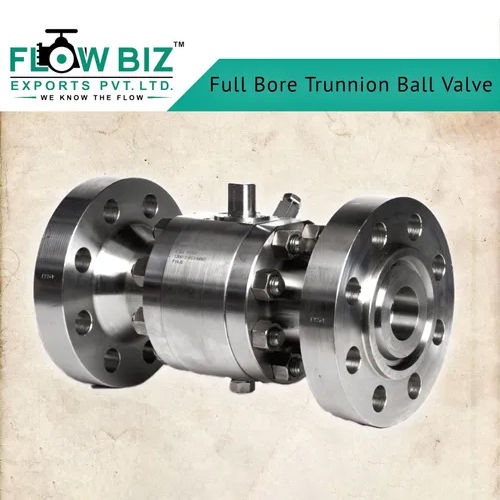

Ball Valve Manufacturer In Amreli

Price 1500 INR/ Unit

Ball Valve Manufacturer In Amreli Specification

- Pressure

- PN16 / PN25 / PN40

- Channels

- 2 Way / 3 Way

- Structure

- Ball

- Caliber

- High Flow

- Connection

- Flanged / Screwed / Socket Weld

- Material

- Stainless Steel / Cast Iron / Brass

- Power

- Manual

- Media

- Water, Oil, Gas

- Temperature of Media

- -10C to 120C

- Port Size

- 1/2 Inch to 12 Inch

- Flange

- ISI Standard / ANSI Standard

- Finish

- Polished / Painted

- Application

- Industrial / Commercial / Agriculture

- Operation

- Quarter Turn

- Size Range

- DN15 to DN300

- Handle Type

- Lever / Gear Operated

- Surface Treatment

- Anti-corrosive Coating

- Seal Type

- PTFE / EPDM / NBR

- End Connection Type

- Threaded / Welded / Flanged

- Testing Pressure

- Hydrostatic 1.5 times rated pressure

- Design

- Full Bore / Reduced Bore

- Body Material

- Forged / Cast

- Life Cycle

- 50,000 cycles (minimum)

About Ball Valve Manufacturer In Amreli

Introduction:

FlowBiz Export Private Limited is a renowned manufacturer and supplier of Ball Valve in Amreli, India.

What industries use ball valves?

Ball Valves:

They are also commonly found in ships' flowing systems, fire-safe protection services, and chlorine manufacturing industries. Ball valve Suppliers state that these valves can be used in various applications and markets, such as gas processing, transmission and storage, industrial, etc.

High-Performance Seal Types

Our ball valves feature premium seal options including PTFE, EPDM, and NBR. These materials ensure reliable, leak-free performance even under demanding conditions, supporting various media like water, oil, and gas. Each seal type is selected to maximize chemical compatibility and operational lifespan, contributing to extended valve life and consistent results across diverse industries.

Versatile Operation & Robust Design

Choose between lever or gear-operated mechanisms, both designed for quarter-turn action, enabling fast and easy flow control. Available in full bore or reduced bore configurations, each valve is engineered for minimal pressure drop and high flow rates. The valve body is crafted from forged or cast materials, providing excellent mechanical strength and stability even in harsh industrial environments.

Compliance and Surface Protection

Every ball valve manufactured is coated with anti-corrosive finishes and rigorously tested at 1.5 times the rated pressure to ensure safety and durability. Our products align with ISI and ANSI flange standards, making them suitable for broad installation requirements. The polished or painted finish further enhances longevity and appearance, ensuring that our valves maintain their performance and visual appeal over time.

FAQ's of Ball Valve Manufacturer In Amreli:

Q: How are your ball valves operated and what options are available?

A: Our ball valves can be operated manually using either a lever or a gear mechanism. The quarter-turn design allows for swift and precise control of flow, making them ideal for industrial and commercial applications requiring dependable shut-off and regulation.Q: What materials and surface treatments are used in manufacturing these ball valves?

A: We manufacture valves using high-quality stainless steel, cast iron, or brass, with each unit treated with an anti-corrosive coating. This combination ensures strength, durability, and corrosion resistance, making our valves suitable for demanding environments and various media types.Q: When should I choose full bore versus reduced bore ball valves?

A: Full bore ball valves are ideal when you need unrestricted flow and minimal pressure loss, commonly used in applications requiring efficient fluid or gas transfer. Reduced bore valves are suited for systems where controlled, lower flow rates are acceptable, offering a more cost-effective solution.Q: Where can these ball valves be installed and what media can they handle?

A: Our ball valves can be installed in industrial, commercial, and agricultural settings. They are designed to reliably handle water, oil, and gas media within temperatures ranging from -10C to 120C and pressures up to PN40, ensuring versatile use.Q: What is the testing process for your valves and how is quality assured?

A: Each valve is hydrostatically tested at 1.5 times its rated pressure to guarantee structural integrity and optimal performance. This rigorous quality control process verifies leak-free operation and compliance with relevant international standards before dispatch.Q: How long do your ball valves last and what maintenance is required?

A: Our valves are engineered for a minimum lifecycle of 50,000 operations. Routine maintenance, such as periodic inspection and cleaning, will help maximize service life. The robust design and high-quality seal materials minimize the need for frequent repairs.Q: What are the primary benefits of choosing your ball valves for industrial projects?

A: Our ball valves offer reliable, durable performance due to advanced sealing technology, robust construction, and secure anti-corrosive finishing. With versatile configurations, compliance with ISI/ANSI standards, and capability to handle harsh media and pressures, they provide a long-term, cost-effective flow control solution for many industries.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Ball Valve Category

Ball Valve Manufacturer in Sachin

Price 4000 INR / Unit

Minimum Order Quantity : 1 Number

Material : Stainless Steel

Finish : Polished

Application : Industrial, Chemical, Water Treatment

Media : Other, Water, Gas, Oil

Ball Valve Manufacturer in India

Price 2400 INR / Unit

Minimum Order Quantity : 1 Number

Material : Stainless Steel

Finish : Polished

Application : Industrial, Chemical, Oil & Gas, Water

Media : Other, Water, Gas, Oil

Metal Seated Ball Valve Manufacturer in Ahmedabad

Price 2000 INR / Unit

Minimum Order Quantity : 1 Number

Material : Other, Stainless Steel / Alloy Steel / Cast Iron / Carbon Steel (WCB, LCB, WC6, WC9, CF8, CF8M) / Duplex Steel

Finish : Anticorrosive Coating / Shot Blasted / Painted

Application : Chemical, Petrochemical, Power, Oil & Gas, Refinery, Pulp & Paper, Mining, Sugar, Steel Plants

Media : Other, Water, Oil, Gas, Steam, Slurry, HighTemperature Fluids

Stainless Steel Full Bore Ball Valve

Price 2500 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Finish : Polished

Application : Industrial

Media : Gas

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS