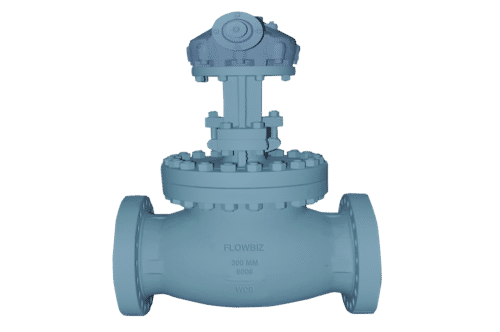

AUDCO (LnT) Make Globe Valve

Price 8000 INR/ Unit

AUDCO (LnT) Make Globe Valve Specification

- Sealing

- Metallic, Soft Seated

- Connection

- Flanged Ends

- Material

- Cast Steel, Forged Steel

- Power

- Manual (Handwheel Operated)

- Pressure

- PN16/PN25/PN40

- Media

- Water, Steam, Oil, Gas

- Working Temperature

- Up to 450C

- Port Size

- DN15 to DN300 (1/2 to 12)

- Surface

- Smooth, Anti-Corrosive Coated

- Shape

- Globe Pattern

- Application

- Industrial Pipeline Flow Control

- Color

- Silver Grey

- Body Material

- WCB / LCB / WC6 / SS 304 / SS 316

- Testing Standard

- Hydrostatic & Pneumatic as per API 598

- Disc Type

- Plug / Ball / Parabolic

- Operation

- Rising Stem

- Face-to-Face Standard

- ASME B16.10

- Packing

- Graphite / PTFE

- Service

- Suitable for Corrosive and Non-Corrosive Fluids

- Available Sizes

- 1/2" to 12" (DN15-DN300)

- Design Standard

- BS 1873 / API 602

- Flow Direction

- Unidirectional

- End Connection Type

- Flanged to ANSI B16.5 / Screwed

- Bonnet Type

- Bolted Bonnet

- Gland Type

- Renewable Gland Packing

- Leakage Class

- As per API 598

- Stem Material

- Stainless Steel

About AUDCO (LnT) Make Globe Valve

AUDCO (L&T) Make Globe Valve

Design Standard: BS 1873

Design Type: Globe Valve Bolted Bonnet Plug / Ball Type Disc

Size Range: 2 inches to 12 inches (50mm to 300mm)

Material of construction: WCB / WC6 / WC9 / LCB / LCC / CF8 / CF8M

End Connection: Flanged End / Buttweld End

Pressure Rating: ASA 150# to ASA 1500#

Testing Standard: API 598

Premium Construction for Durability

AUDCO (LnT) Globe Valves are constructed from a wide range of materials, including cast and forged steel, as well as stainless steel grades. The robust bolted bonnet and anti-corrosive surface coating extend the lifespan of the valve, even in aggressive industrial environments. Their silver-grey finish and renewable gland packing provide both aesthetic and functional longevity.

Versatile Compatibility and Sizing

Engineered for flexibility, these globe valves accommodate various piping needs with flanged (ANSI B16.5) or screwed ends, and sizes ranging from 1/2" to 12" (DN15-DN300). The rising stem, unidirectional flow, and customizable disc and packing options make them suitable for applications in water, steam, oil, and gas services.

Stringent Testing and Certification

Every valve undergoes thorough hydrostatic and pneumatic testing following API 598 protocols to guarantee dependable sealing and minimal leakage. Certified for usage with corrosive and non-corrosive fluids, AUDCO (LnT) globe valves consistently meet international quality and safety standards.

FAQ's of AUDCO (LnT) Make Globe Valve:

Q: How does the AUDCO (LnT) Globe Valve operate?

A: The valve features a rising stem mechanism controlled by a manual handwheel. This design moves the disc upward to allow flow or downward to restrict flow, providing precise control ideal for regulating fluid in industrial pipelines.Q: What industries can benefit from using this globe valve?

A: Due to its robust design and material versatility, the valve is suitable for industries like water treatment, oil & gas, chemical processing, steam distribution, and power generation, where accurate flow regulation and durability are essential.Q: When should you choose a globe valve with unidirectional flow and which media is it compatible with?

A: A unidirectional globe valve is ideal when flow control in one direction is essential for process safety. It is compatible with water, steam, oil, and gas, including both corrosive and non-corrosive fluids.Q: Where are these globe valves manufactured and supplied from?

A: AUDCO (LnT) globe valves are manufactured, exported, and supplied from India by leading valve producers, ensuring quality and timely distribution across global markets.Q: What is the testing process for this globe valve?

A: Each valve is subjected to hydrostatic and pneumatic testing as per API 598 standards. This ensures leak-tight performance, reliable sealing, and compliance with stringent industry requirements.Q: How do you select the suitable body and stem material for your application?

A: Selection depends on the fluid's corrosiveness, temperature, and pressure conditions. Stainless steel bodies and stems are ideal for highly corrosive media, while WCB or LCB options suit less aggressive environments. Consult application specifics for optimal material choice.Q: What are the key benefits of using a bolted bonnet and renewable gland packing?

A: A bolted bonnet provides enhanced strength and ease of maintenance, while renewable gland packing allows quick replacement, minimizing downtime and ensuring continuous, leak-free operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Globe Valve Category

Globe Valve Manufacturer in India - Flowbiz

Price 3000 INR / Unit

Minimum Order Quantity : 1 Number

Color : Silver

Surface : Other , Polished

Angle Globe Valves Manufacturer in Vadodara

Price 2000.00 INR / Unit

Minimum Order Quantity : 1 Number

Color : Blue

Surface : chrome Plating

Size : 1/2" to 12"

Usage : Industrial

Angle Type Globe Valve Manufacturer in Jamnagar

Price 700 INR / Unit

Minimum Order Quantity : 1 Number

Color : Silver

Surface : Galvanized

Size : All size

Usage : Construction

Globe Valve Manufacturer in Jamnagar

Price 800 INR / Unit

Minimum Order Quantity : 1 Number

Color : Gray

Surface : Powder Coated

Size : All size

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free